Photovoltaic cells are composed of many precise components, including electronic components, which require sealant for encapsulation protection. It is particularly important to choose the right adhesive. Among them, the performance of silicone right adhesive is particularly outstanding, so why choose silicone adhesive for PV modules?

Silicone adhesive sealant structure is relatively special, which has high thermal stability, works at high temperatures, the chemical bond will not be easily decomposed and broken, and mechanical properties will not change with the change of temperature; silicone is used in outdoor environments, will not be easily decomposed by ultraviolet rays and ozone; silicone's electrical insulation properties are very good, able to arc, voltage, corona, play good insulation, as far as possible to reduce the short-circuit and so on. The electrical insulation property of silicone is very good, can resist arc, voltage, and corona, play good insulation, and minimize short circuits and other accidents. In addition, the waterproof and moisture resistance of silicone adhesive is also good, can effectively block moisture and water, and will not affect the normal work of the components. Because of these properties, it is suitable for use in photovoltaic and other industries.

The following from 5 aspects of silicone in the application of photovoltaic components:

- What are the features of silicone materials?

- What is the composition of photovoltaic modules?

- How to apply silicone sealant in the photovoltaic module?

- How to apply silicone potting compound in the photovoltaic module?

- How to make silicone gel performance better?

1. What are the features of silicone materials?

Silicone-strong adhesives are widely used in many fields because of their excellent performance.

(1) Aging resistance

Its aging resistance is outstanding, which can resist the erosion of ultraviolet rays and ozone so that the silicone in long-term exposure to harsh environments can still maintain stable performance and does not easily cause aging and cracking when household repairs.

(2) Temperature resistance

Silicone has excellent resistance to high and low temperatures and can maintain its physical and chemical properties in extreme temperature changes, making it suitable for a variety of working environments from extreme cold to extreme heat.

(3) Electrical insulation

In terms of electrical insulation properties, silicone has high dielectric strength and maintains good insulating properties even in wet environments, making it an ideal insulating material for electronic and electrical equipment.

(4) Hydrophobicity

Silicones are extremely hydrophobic and do not easily adhere to moisture and grease on their surfaces, making them excellent in water- and oil-resistant applications.

(5) Inert

The biological inertness of silicone materials means that they are non-irritating to biological tissues and are not easily absorbed by living organisms, so they are commonly used in medical devices and implants to minimize the body's rejection of the materials. These combined properties make silicone a versatile and reliable material choice that is featured best-selling.

2. What is the composition of a photovoltaic cell module?

(1) Tempered Glass

Tempered glass is an important part of the PV module, its role is to protect the PV cell and provide light transmission, which can withstand large temperature differences between day and night and adverse weather conditions. The tempered glass needs to be characterized by high light transmittance (generally 91% or more) and ultra-white tempered treatment.

(2) EVA (Ethylene and Vinyl Acetate copolymer)

EVA is a hot melt adhesive used for bonding and fixing tempered glass and photovoltaic cell sheets. It provides bonding strength but also enhances the light transmission of PV modules. However, EVA exposed to air is prone to aging and yellowing, which can affect the light transmittance and power generation quality of the module. Therefore, the technical requirements for EVA in encapsulation are very high.

(3) Photovoltaic cell

The photovoltaic cell is the core material of solar photovoltaic modules, and its main role is to generate electricity. There are two types of mainstream cells on the market: crystalline silicon solar cells and thin-film solar cells. The former equipment cost is relatively low, but consumption and cell cost are high, and the photoelectric conversion efficiency is also high, suitable for outdoor sunlight power generation. The latter equipment cost is relatively high, but consumption and cell cost are low, photoelectric conversion efficiency is relatively low, but has excellent performance in low-light environments.

(4) Backplane

The role of the backplane is to seal, insulate, and waterproof, usually using TPT, TPE, and other materials. These materials must be able to resist aging to ensure the long-term service life of the PV module. The presence of a back sheet helps enhance the aging and corrosion resistance of the PV module.

(5) Aluminum alloy frame

An aluminum alloy frame protects the entire panel power generation system, playing a sealing and supporting role. Its strength and corrosion resistance is excellent, and it can effectively protect the photovoltaic module from the influence of the external environment.

The main role of the battery module installation frame: first, it can protect the glass edge of the component after lamination; second, it can combine with silicone edging to strengthen the sealing performance of the component; third, it greatly improves the overall mechanical strength of the battery module; fourth, it can facilitate the transportation and installation of the battery module.

(6) Junction box

The role of the junction box is to protect the entire power generation system, it plays a role in sealing and waterproofing the wires leading out of the PV module and ensuring the safety of the PV module system operation. The most critical part of the junction box is the diode, the choice of which depends on the type of cell within the module.

In the production of battery modules, in order to ensure the performance and efficiency of battery modules, the selection of the junction box should not only choose the specifications of the size of the junction box, load-bearing power, operating current and operating voltage, etc., but also take into account the contact resistance of the junction box itself and the heat dissipation performance, as well as the bypass diode in the junction box, the on-state voltage drop, the junction temperature, the coefficient of thermal resistance, and so on.

(7) Silicone adhesive

To prevent water and oxygen in the air into the solar photovoltaic module, the module in the silicon cell has oxidation, which results in a reduced conversion rate of silicon cells must be a photovoltaic module frame (i.e., the panel to the sunny side of the glass panels, the reverse side of the TPT boards and aluminum frames) gap using adhesive sealing with good weather aging performance; in the power converter box (i.e., the junction box) shell must also use sealant for adhesive sealing to protect the circuit board and extend the service life.

As a sealing material, silicone adhesives are used to bond the panel to the solar frame, as well as the junction between the component and the junction box.

Generally, silicone adhesive used for battery components has two kinds, one is neutral one-component silicone sealant, used for components and aluminum profile frame and junction box adhesive sealing:

① It has room temperature neutral curing and deep curing speed so that the surface of the components can be cleaned cleaning work after 3 hours;

② It has good sealing, and good adhesion to aluminum, glass, TPT, TPE backplane materials, junction box plastic, and so on;

③ The colloid is resistant to high temperature and yellowing, unique curing system, and has good compatibility with various types of EVA.

④ It can improve the ability of components to resist mechanical vibration and external impact.

The other is a two-component silicone thermal conductive adhesive, used for junction box potting. This silicone is a new type of thermally conductive insulating material synthesized with silicone:

① It has room temperature curing, fast curing, curing without heat, no corrosion, small shrinkage;

② It can be in a wide range of temperatures (-60 ~ 200 ℃) to maintain rubber elasticity, excellent electrical properties, and good thermal conductivity;

③ It is waterproof and moisture-proof, resistant to chemical media, resistant to yellowing, climate aging for more than 25 years;

④ It has good adhesion with most of the plastic, rubber, nylon, and other materials.

3. How to apply silicone sealant in the photovoltaic module?

PV sealant plays a vital role in the manufacturing and maintenance of PV modules. Its main role is to provide sealing and bonding for PV modules, to ensure that the internal components are not subject to moisture, dust, gas, and other environmental factors of erosion, so as to protect the solar cell slices and circuits, to extend the service life of PV modules.

(1) Silicone adhesive sealant is widely used in the photovoltaic industry because of its excellent chemical stability and mechanical properties. Silicone sealants have a very high tolerance to ultraviolet light, ozone, and extreme temperatures, can maintain its performance does not decline even for a long time outdoor use. This stability means that silicone sealant can maintain its sealing performance in a variety of climatic conditions, to prevent environmental factors on the photovoltaic module damage.

(2) In terms of mechanical properties, silicone sealant has good flexibility, and ductility, it can adapt to the photovoltaic module in the temperature change or mechanical stress under the action of small deformation, without brittle cracks or fall-off. This flexibility ensures a long-term good adhesion between the sealant and the component, improving the overall structural stability.

The protective effect of silicone sealants has been fully verified in actual cases. For example, in extreme environments such as seaside or desert photovoltaic power plants, photovoltaic modules using silicone sealants show lower failure rates and longer maintenance intervals. After several years of use of some PV modules, those using silicone sealants still maintain good electrical performance and structural integrity, while those poor quality sealants show corrosion, cracking, short shelf life, and other problems. If it needs to remove sealants when household repairs, we can use a sharp knife.

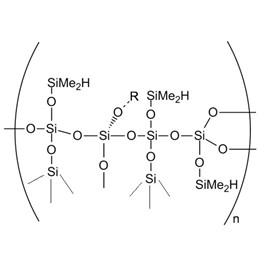

XJY-8207 S / M Hydrogen MQ Resin can be used as a raw material for silicone tackifiers used in silicone bonding sealants.

XJY-8206N Series Solution Type Methyl Vinyl MQ Silicone Resin is a colorless and transparent liquid resin, consisting of Vinyl MQ silicone resin and Vinyl silicone oil, which can be used for LSR, liquid addition molding silicone rubber, but also can be used for another two-component addition adhesive.

4. How to apply silicone potting compound in the photovoltaic module?

Silicones play a vital role in the application of PV potting compounds. PV potting adhesive is a key material used to encapsulate PV modules, and its performance directly affects the stability and service life of PV modules. The silicone material is widely used in the PV potting compounds manufacturing process because of its unique performance advantages.

(1) Silicone has excellent insulating properties. In the photovoltaic module, the potting compound needs to play a good insulating role to prevent current leakage and short circuit phenomena. The high-insulating properties of silicone materials ensure the safe and stable operation of photovoltaic modules.

(2) Silicone materials have excellent weathering and aging resistance. Photovoltaic modules are usually installed in outdoor environments and are subject to long-term erosion by natural factors such as sunlight, rain, wind, and sand. Silicone potting compounds can resist these harsh environments and maintain stable performance, thus extending the service life of PV modules.

(3) In addition, silicone materials also have good adhesive and curing properties. It can form a good bond with various materials in the photovoltaic module to ensure the sealing and stability of the component. At the same time, silicone potting compounds can form a solid colloidal structure during the curing process, providing strong support and protection for photovoltaic modules.

In practice, silicone potting compounds are widely used in the encapsulation process of photovoltaic modules. Through precise proportioning and construction techniques, silicone potting compounds can effectively fill the gaps and holes in PV modules, ensuring the integrity and sealing of the module. At the same time, it can also improve the impact resistance and seismic performance of PV modules, enhancing the reliability and safety of the modules.

XJY-8205 Powder Series Methyl MQ Silicone Resin is a solid powder resin that can be used as a reinforcing material for liquid silicone rubber. Adding MQ resin into the potting compound can enhance the high and low-temperature resistance and prolong the service life of the sealant. It is a solid and good bond to various materials, applied to many electronic components in the power supply and household repairs.

5. How to make silicone better performance?

Silicone is a polymer material with silicone as the main component, also known as silicone rubber. The silicone sealant is a single component, it is more convenient in construction (household repairs), and the main performance is to bond and fix the electrical components. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone resin products can meet the needs of the silicone adhesive field and support the provision of diversified customized solutions. Email address phone number please click contact us.