Silicones typically have a low environmental impact, while some grades of silicone are highly susceptible to degradation under extreme conditions. This limits the usefulness of silicones in high-performance application scenarios where demand is high. Recent trends in the silicone industry are reducing their environmental impact while diversifying their uses.

This article highlights modern silicone technologies such as silicone 3D printing, advanced adhesives, and functional coatings. In addition, new silicone formulations enhance resistance to extreme temperatures and pressures, expanding their potential for demanding high-performance materials.

- Advanced Adhesives & Sealants

- Additive Manufacturing

- High-performance Polymers

- Flexible Medical Dressing

- Functional Coatings

- Tailored Silicone

- Thermal Management

- Biocompatible Products

- Implant Imaging

For an in-depth study of the top silicone trends and startups, a sample of 568 startups and scale-ups from around the world was analyzed. This data-driven study provides innovative intelligence, outlining the top trends and 20 promising startups in the silicone industry.

1. Advanced Adhesives and Sealants

Most traditional adhesives and sealants are highly susceptible to adhesion, temperature resistance, and flexibility failures under extreme conditions. As a result, several startups are developing silicone-based adhesives and sealants to improve the performance of these materials. They offer stronger adhesion, higher resistance to high and low temperatures, and the ability to bend without losing adhesion. This makes them an effective solution for high-performance critical applications in the renewable energy, aerospace, and aviation industries.

DeepMaterial Develops Silicone Optical Adhesives

DeepMaterial is a Chinese startup focused on bonding and protecting high-end materials for semiconductors and electronics. Its silicone optical adhesives are characterized by flexibility, optical transparency, and strong adhesion to different substrates. It also ensures minimal distortion and accurate color reproduction and can bond materials such as polyethylene terephthalate or indium tin oxide.

In addition, it is resistant to environmental factors and mechanical stress, so it can be used to create durable, high-quality flexible screens. The startup also offers a range of materials for adhesive and film applications in areas as diverse as communication terminals and semiconductor packaging.

Medicud develops medical-grade silicone adhesives

Italian startup Medicud produces Dryum, a mechanically powered device for incisional negative-pressure wound therapy. It is a single-use, portable solution that utilizes a silicone adhesive for dressing changes and an advanced dressing material to enhance fluid drainage.

In addition, Dryum provides continuous negative pressure to promote the healing of surgical wounds. It provides a cost-effective and adaptable method for treating wounds of all sizes and shapes. For patients, Dryum ensures silent, comfortable healing while reducing the risk of infection.

NanoRial Technologies Develops Carbon Nanotube (CNT) Based Additive

Canadian startup Nanorial focuses on exfoliation technologies for the efficient dispersion of carbon nanotubes on a large scale. Its ANTIS-SIL carbon nanotube additive enhances the antistatic and conductive properties of various silicone compounds. The additive ensures ultra-low carbon usage in products, supports a wide range of colors and eliminates hot spots through uniform filler dispersion.

The startup's additive also enhances mechanical strength without significantly changing viscosity or density. In the silicone industry, it finds applications in conductive inks, coatings, adhesives, and silicone electrode materials.

2. Additive manufacturing

Silicon-based additive manufacturing is challenging due to its inherent slow production speeds and the complexities associated with gravity-influenced material deposition. To address this issue, the silicone industry has adopted hybrid manufacturing, VAT photopolymerization, direct ink writing (DIW), and free-form reversible embedding. These technologies have improved the printability of silicones, making them more suitable for mass production.

In addition, these advanced printing technologies utilize optimized material formulations and real-time monitoring and control systems. They increase production speeds, improve shape fidelity, and ensure consistent material deposition. These benefits pave the way for more reliable and efficient silicon-based additive manufacturing.

3Deus Dynamics develops a cloud warehousing platform

French startup 3Deus Dynamics is advancing 3D printing technology through its additive manufacturing process, dynamic molding. This method fuses 3D printing with injection molding to process injectable materials without chemical modification. The granular medium used in Dynamic Molding imparts functional properties to the final product, resulting in the creation of composite materials.

Additionally, Dynamic Molding enables rapid manufacturing, with speeds of up to 100 millimeters per second in the development of parts. The startup's printing method solves problems such as structural collapse during the printing process and enables the use of various injectable silicones without reformulation.

Lynxter Advances Multi-Material 3D Printing Technology

Lynxter is a French startup offering thermoplastic, ceramic, and silicone 3D printing. It integrates various processes to provide connectivity and adaptability. The startup's products include the S600D modular 3D printer, which has interchangeable tool heads and supports multiple materials.

The Lynxter S300X is the company's silicone and polyurethane 3D printer for medical and industrial applications. It also prints silicone elastomers with different Shore hardnesses and viscosities. Its 3D printing method reduces the number of manual interventions in the production of orthotics and prosthetics.

Prayasta 3D Inventions Offers Implant-Grade Silicone Printer

Indian startup Prayasta 3D Inventions utilizes advanced manufacturing technology to create soft tissue implants and prostheses. The startup's Silimac P250 3D printer prints implant-grade elastomers such as silicone to ensure reliable and continuous production. This industrial-grade 3D printer can run continuously over long production runs and can hold up to 14,000 mL of silicone per fill.

In addition, the printer maintains a sterile environment to produce high-quality products suitable for medical applications. The startup's implantable elastomer additive manufacturing (iEAM) technology is tailored for implantable silicone, facilitating the development of personalized medical solutions by adapting to each patient's requirements.

3. High-performance polymers

Many silicone-based materials and polymers are physically or chemically unstable and degrade over time. To address this issue, innovative products such as reactive silicone polyesters and branched silicones are being increasingly adopted. This also ensures that polymers retain their properties and functionality even in oxidizing environments.

This improvement extends the service life of silicone products and broadens their application scope in industries where oxidizing conditions are prevalent. This synergy opens up new potential for silicones in aerospace, chemical processing, and other areas where materials are subjected to mechanical stress and harsh environmental conditions.

Siloxene develops polysiloxane resin technology

Swiss startup Siloxene produces Q-T polysiloxane dendritic polymer resins, which are specialized for coatings, adhesives, and sealants. Its proprietary Q-T polysiloxane resin technology provides the foundation for high-performance materials and creates hydrophobic and amphoteric compounds for sustainable products.

The Q-T polysiloxane platform enhances performance by utilizing intricate chemical interactions at specific material interfaces. In addition, Siloxene's Q-T polysiloxane-derived raw materials and additives improve the cohesive strength of the adhesive resin matrix and the bond between resin and fiber.

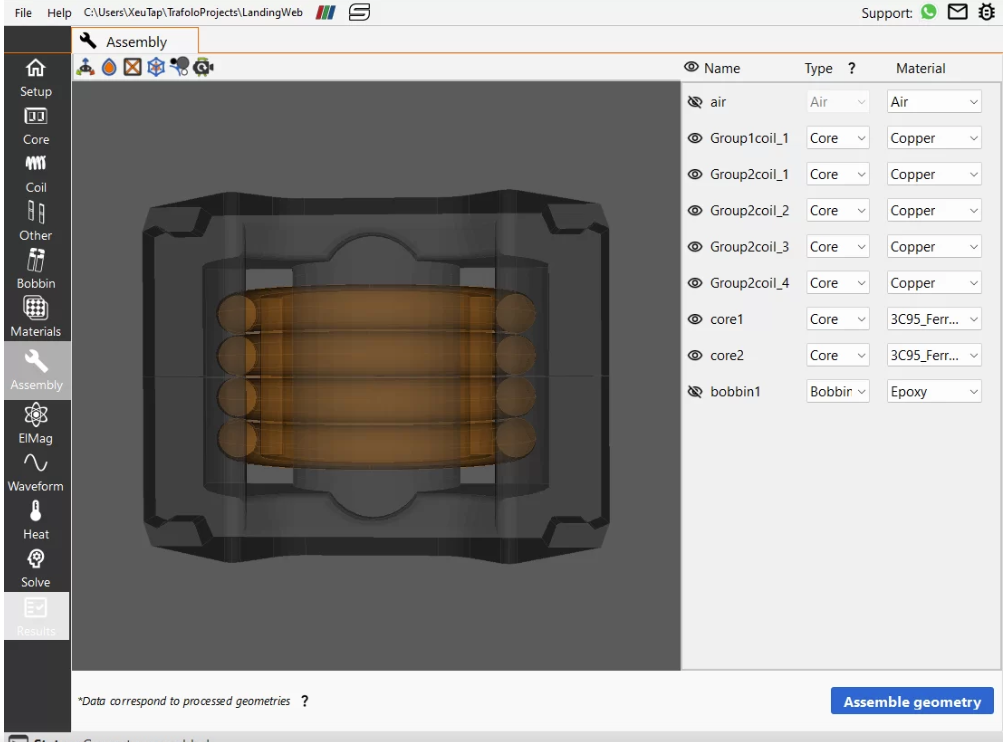

TRAFOLO Magnetics Offers Component Simulation

Polish startup TRAFOLO Magnetics specializes in the development of simulation software for magnetic component design, with a focus on high-performance silicon-based components. The startup's software is a three-dimensional finite element method (FEM) simulation tool customized for power electronics that integrates coupled electromagnetic and heat transfer solvers. For example, the software can simulate soft core inductors with boundary compounds such as silica gel.

In addition, the software provides a user-friendly interface with templates and examples. This helps to simulate the low-frequency electromagnetic behavior of transformers and inductors. TRAFOLO Magnetics' solutions enable engineers to leverage this technology to digitally test transformer models in a variety of configurations, geometries, and situations.

SiLIM Technologies Produces Amino Silicone Emulsions

Chinese startup SiLIM Technologies produces innovative silicone materials for high-performance applications in a variety of industries. Its amino silicone emulsions are polysiloxane materials with an oversized molecular structure that incorporate amino groups through emulsion polymerization. This results in products with improved smoothness, softness, and wash durability.

The introduction of hydroxyl groups further enhances the film properties and reduces the oil content of the product. Key applications for such emulsions include leather conditioners, fabric and fiber softeners, and shampoo additives. siLIM Technologies' products, including amino silicone emulsions, are used in automotive, electronics, healthcare, and construction applications.

4. Flexible medical dressings

Silicones are known for their biocompatibility and softness, but they can sometimes cause skin irritation or discomfort in long-term medical applications, especially when used on patients with fragile skin. By combining silicone with novel materials and technologies, the startup has created a dressing that both optimizes the inherent properties of silicone and minimizes potential irritation.

The dressing offers enhanced breathability, moisture management, and skin contour adaptation. This also ensures greater patient comfort and promotes faster wound healing without the drawbacks traditionally associated with silicone dressings.

Brella Health Brella Health makes flexible silicone bandages

U.S. startup Brella Health has introduced a bandage that addresses the challenges of wound dressing in clinical settings. Its product, Bubble, is a dome-shaped flexible silicone bandage used to pack wounds in hospitals.

The Bubble bandage solves the problems of insufficient adhesive integrity and skin breakdown associated with typical medical dressings, making it an effective alternative. The startup's approach to wound care reduces the need for dressing changes, resulting in less product waste and, lower risk of infection.

Pharmadome Creates a Wound Spacer-Shield

Pharmadome, an Italian startup, produces a silicone medical dressing that can be used as a wound spacer shield, made of hypoallergenic medical grade TPE. The perforated cup-shaped shield, called SIMOPOD, has a modular design that allows sections to be removed to accommodate different-sized wounds. Unlike traditional dressings, it serves as a protective barrier between the wound and traditional medical dressings, ensuring that the wound remains undamaged.

SIMOPOD's semi-rigid structure with special small holes creates a sterile environment that promotes natural drying and rapid wound healing. The design also facilitates adequate ventilation for the application of creams or ointments. In addition, its modular design makes it suitable for wide or irregular wounds.

5. Functional coatings

Silicone coatings are problematic in terms of their curing mechanisms and ability to provide sustainable, long-lasting protection, especially in harsh environments. Innovative technologies such as UV-curable silicone release systems address this issue. They are based on silicone acrylates and provide a more efficient curing process through a free radical mechanism.

In addition, the development of nano-silicone wax coatings offers a protective, transparent, and reversible solution. This facilitates the protection of delicate materials. These coatings ensure a long-lasting and consistent surface effect and also provide additional functions such as antimicrobial or enhanced UV resistance.

YUKA Performance Chemicals produces silicone-based surfactants

Turkish startup YUKA Performance Chemicals focuses on specialized surface modifiers for waterborne coatings. Its product DENSURF SM 102 enhances the wetting and spreading ability of coatings by reducing their surface tension. As a result, it prevents surface defects and ensures a smoother finish.

The chemical structure of DENSURF SM 102 consists of a polyether-modified polydimethylsiloxane, which provides unique properties for coatings. It can be used in architectural coatings, printing inks, and wood coatings.

Excellence Coatings Manufactures Easy-Clean Coatings and Additives

Excellence Coatings is a German start-up company specializing in anti-stick coatings. Its silicone surface additive Aversil 936 for EB coatings provides long-lasting easy-clean and tape release. The company's other products, Aversil 824 and 412, are silicone additives for UV coatings that reduce surface tension and provide permanent easy-clean effects.

The company's products vary in polymer structure and viscosity, allowing for cost-effective modification of coatings. Its coatings and additives are used in a wide range of applications, such as keeping surfaces clean.

6. Customized silicones

Common silicone formulations offer a wide range of properties, but may not meet specific needs, resulting in poor performance in particular applications. As a result, startups are customizing silicones by introducing specific functional groups or altering polymer chains to achieve desired properties.

Whether it is to enhance the biocompatibility of medical implants, electrical conductivity, or UV stability, these customized silicones ensure optimal performance in specific environments and applications.

ROMAKK Chemicals Offers Silicone Derivatives

ROMAKK Chemicals is an Indian startup producing customized silicone solutions. Its silicone derivatives improve the softness and elasticity of fabrics. They are also effective water repellents in the construction industry, protecting surfaces from environmental factors.

In addition, the company's defoamers prevent the formation of foam, which is critical in industries such as water treatment and textiles. Antifoam products come in a variety of forms, such as water-based products for water treatment, oil-based products for refineries, and powder-based products for detergents. The company's tailor-made silicone solutions meet the needs of different industries through their versatile applications.

UNIQ Chemicals produces silicone oils

Turkish startup UNIQ Chemicals produces silicone oils, which are necessary for emulsifying and manufacturing a variety of industrial products. Its AKSILOX RAF 210 is an activated amino-functional silicone oil designed for polyester (PES) fabrics. Another variant, AKSILOX RAF 440, is a non-hydrophobic silicone oil for all fiber types.

In addition to these products, the company's silicone fluids are available in different amine values and compositions to meet a wide range of requirements and ensure optimum performance. They can be used as base materials or as excipients with properties such as hydrophobicity.

7. Thermal management

A major challenge for all electrical systems is the lack of efficient and rapid heat dissipation. Silicone-based materials address these thermal challenges through innovative technologies such as the incorporation of thermally conductive fillers or improvements in the structure of the silicone matrix.

Such silicone products for thermal management dissipate heat efficiently, ensuring that devices maintain optimal operating temperatures. As a result, the service life of these components is extended and the risk of heat-related failures is greatly reduced.

ElastaPro offers solid silicone sheets

ElastaPro is a U.S.-based startup company that manufactures high-temperature grade silicone sheets. This sheet uses advanced heat stabilizer technology to provide higher temperature resistance. It also offers better electrical insulation and is suitable for seals and gaskets. Other features of this material include UV and ozone resistance, non-toxicity, and chemical inertness.

In addition, the sheet maintains extremely high tensile strength, elongation, and tear strength after being left in a high-temperature environment for several hours. As a result, ElastaPro sheets are effective in applications such as insulation panels, exhaust systems, and food processing that require higher temperature resistance than general-purpose silicones.

Aarkay Develops Silicone-Based Encapsulation Material

Indian startup Aarkay produces encapsulants for electronic devices. These encapsulants have a medium Shore A hardness, which facilitates rework in case of failure. In addition, the startup's silicone potting products have a medium viscosity to ensure easy flow and are available in various ratios.

The high thermal conductivity of the potting compounds ensures optimal performance, whether in LED lighting or electronic power supplies. In addition, silicone potting and encapsulation compounds are resistant to water, chemicals, shock, voltage discharge, vibration, physical damage, and flame.

8. Biocompatible Products

Certain silicon formulations can lead to adverse immune reactions or complications after long-term implantation in the body. Startups are addressing this issue by improving the synthesis process and introducing bio-friendly additives.

Biocompatible silicone variants enhance compatibility with biological systems, minimizing adverse reactions and ensuring safer and more effective use in products. This includes medical devices, implants, and other healthcare devices.

NK TECH Offers Flexible Prosthetics

NK TECH is a Polish startup that produces sockets for orthopedic surgery, focusing on post-amputation needs. The startup's product, Silint, serves as an internal soft prosthetic socket that works in conjunction with an external hard socket. It also provides a secure fit for an amputee's remaining limb to provide comfort and safety.

Another NK TECH product, PneumoSilint, allows precise socket sizing to accommodate fluctuations in residual limb volume. This is achieved by means of an air chamber in the silicone wall, which can be adjusted by means of a pump. The medical silicone ensures biocompatibility and prevents allergies and skin sensitization.The design of PneumoSilint also contributes to the stabilization of the prosthesis, enhancing motion control and safety.

Functional Restorations Offers Customized Breast Implants

U.S.-based startup Functional Restorations specializes in custom silicone and 3D-printed prosthetic restorations for people with missing or defective anatomy. The startup creates breast prostheses based on a woman's specific shape and skin texture to provide comfort and realism. By personally coloring the implants, they can be hand-painted to match the individual's skin tone.

The startup's prosthesis fabrication process includes a pre-surgical digital scan that captures accurate digital images of the breast anatomy prior to surgery. Additionally, Functional Restorations' digitally-assisted manufacturing technology helps create personalized prosthetic sculptures.

9. Implant imaging

In diagnostic imaging such as MRI or ultrasound, medical implants can sometimes create artifacts or obscure surrounding tissue. To address this problem, innovations in implant imaging technology incorporate specific markers or use advanced detectors to obtain higher-resolution images.

In addition, startups are developing implants that are more compatible with imaging technologies. These advances ensure clearer and more accurate imaging results. They enable healthcare professionals to monitor, diagnose, and plan treatment more effectively without the interference of traditional silicone-based implants.

AB-CT Advances Breast Diagnostic Imaging Technology

The German startup AB-CT offers diagnostic breast imaging through its product nu: view. It is a CT scanner for the breast utilizing spiral CT and photon counting technology. The product can also perform non-compression scans for women with implants.

Unlike conventional scintillation, nu: view utilizes a direct conversion detector made of cadmium telluride (CdTe). The technique offers high image resolution, low radiation dose, and short scanning time compared to current mammography.

The development of eco-friendly silicone derivatives reduces the environmental footprint during production and disposal. These green alternatives also maintain the high-quality standards expected of conventional silicones. In addition, innovations in the recycling and reuse of silicones have contributed to the development of a circular economy.

In addition, the combination of nanotechnology with silicones has enhanced the material's properties, from improved electrical conductivity to increased strength. The silicone industry trends and startups outlined in this report only scratch the surface of the trends identified during the data-driven innovation and startup scouting process.

Discovering new opportunities and emerging technologies and applying them to your business can go a long way toward gaining a competitive advantage, capitalizing on trends, and advancing together.