XJY-801 For Industry

Polymethylsilsesquioxane ( Spherical Silicone Resin Powder)

PIONEER IN SILICONE RESIN

XJY-801 spherical silicone resin is a widely used light diffusing agent. The difference in refractive index between spherical silicone resin and plastic base material can achieve the effect of light diffusion. Light from a single direction can be diffused into various directions inside the diffusion material with spherical silicone resin. At the same time, it can be used as a wear-resistant modified material. Due to the characteristics of silicone materials, spherical silicone resins also have related applications in personal care.

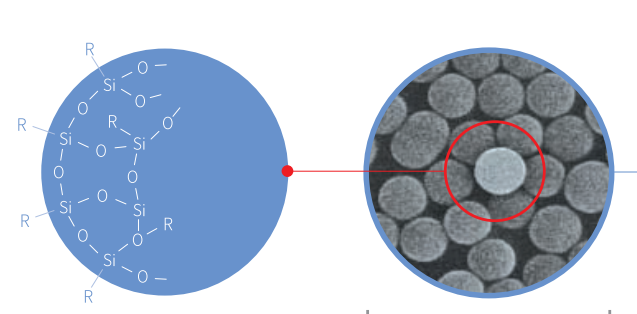

| Polymethylsilsesquioxane is a kind of silicone microspheres with a three-dimensional structure connected by the Si-O bonds, the polymer formed with hydrolysis and condensation. |  |

The chemical structure of the insoluble, non-melting tri-functional components of dense cross-linked curing resin. Polymethylsilsesquioxane silicone resin is a white powder, and when adding it to resins of different materials, it will be uniformly dispersed in the matrix as a fine transparent glass sphere. Through the difference in refractive index with different substrates, direct light source penetrating refraction, and the travel route of diffused light output is changed to achieve the purpose of uniform light and light transmission, make the led lighting be soft light and meet the requirements of haze value and light transmittance at the same time.

The silicone light diffuser is a kind of micron-scale silicone microsphere powder, which is mainly used for the light-diffusing effect of different refraction with PC, PMMA, PS, PP, camera flash to diffuse light. Its products are mainly used for LED light diffusers, the led light panel, lampshades, light diffuser materials and can provide a good balance between transmittance and diffusivity, good dispersion and stability, and can provide a variety of particle sizes.

The most important performance of PMSQ depends on haze and light transmittance. PC light diffusion agent is more suitable for 2um (XJY-8012) with the highest light transmittance and less haze, while TV light diffuser panel diffusion agent is matched with 1.3um particle size (XJY-80113). According to the different refractive index between the light diffuser panel and PMSQ, the light will change its route when passing the light diffuser panel to achieve the light diffusion effect.

1. Compared with inorganic light-diffusing agents, it has high diffusion efficiency, good compatibility with the matrix resin, good dispersibility, small specific gravity, low water absorption, good hydrophobicity, and more balanced light transmission and uniformity;

2. Compared with traditional acrylic light-diffusing agents, it has high light-diffusing efficiency, high brightness which can maintain ideal light transmittance, low addition amount so it is cost-effective;

3. Compared with the acrylic light diffusing agent, it has a better heat resistance and high-temperature resistance and has a longer service life of a lamp tube lightbox lamp shade.

| PC, also known as polycarbonate, can also be made into a light diffusing sheets such as lighting PC lampshades/tubes, lighting PC diffusers, PC tubes, etc. Since XJY-801 spherical silicone resin and polycarbonate have different light refractive indices, spherical silicone resin can be kneaded into polycarbonate, and composite material with a light-diffusing effect can be made. |  |

However, there are relatively many problems encountered in the use of PC light diffusers. The following three types of common problems are listed.

One is that the particle size distribution of Polymethylsilsesquioxane resin is wide, and some small particle sizes cause the light to diffract and transmit yellow light;

The second is that the water and residual alkali in resin cause the micro degradation of PC.

Due to the characteristics of silicone resin, the refraction is low, so it cannot provide high light transmittance. At present, it is generally used in combination with 801 with large particle size in the case of opaque lamp beads to ensure light transmittance; the second is It is used in combination with the light-diffusing agent of acrylic resin;

The reason is that the light diffusing agent itself has agglomerates, or under high-temperature conditions, due to the residual hydroxyl or alkoxy group of pmsq, it condenses and agglomerates to block the network.

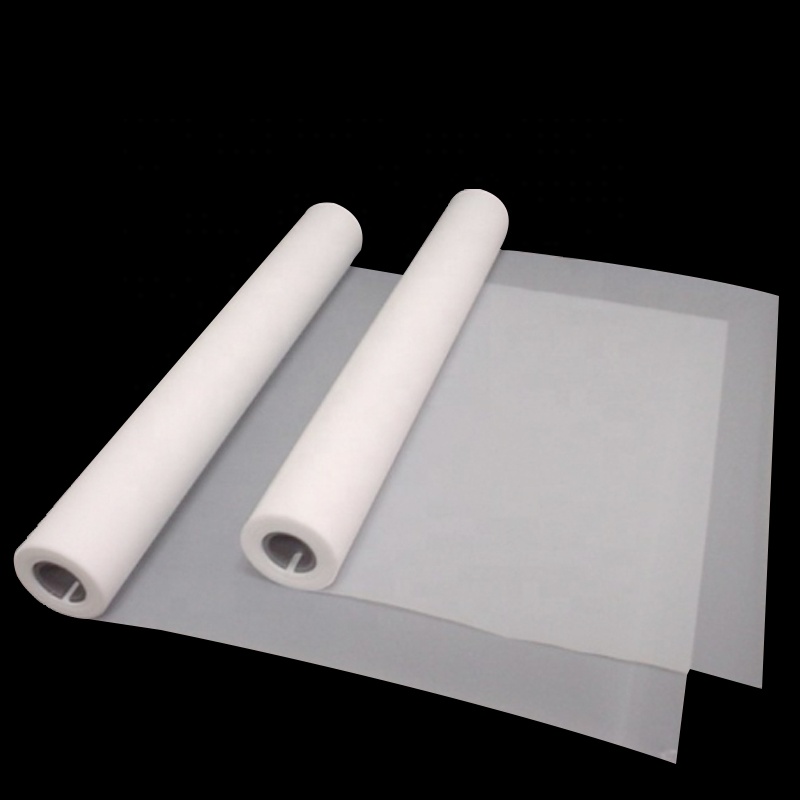

The PET light diffusion film production was prepared with silicone and polyacrylate light diffuser particles. Under the same addition amount, the particle size of the silicone light diffuser was larger, and the haze of the light-diffusing film was lower; the higher the addition of the same light diffuser, the higher the haze and the lower the light transmittance; with the increase of the stretching ratio, the haze of the silicone light-diffusing film decreased and the light transmittance increased. Silicone microspheres can greatly improve the haze of thin films while maintaining high light transmittance.

What is the MOQ of Polymethylsilsesquioxane?

For our existing regular in-stock products, the MOQ starts from 1 piece.

If you would like to customize a product with a specific specification, please contact us to determine the MOQ.

What is the capacity of Polymethylsilsesquioxane?

MQ resin powder line Capacity: 200 tons/m

VMQ silicone resin powder line Capacity: 100 tons/m

Do you offer a delivery service for Polymethylsilsesquioxane?

Of course, we are happy to provide our customers with a substitute shipping service.

We also offer a courier service with different prices and delivery times depending on your needs.

Your order will be delivered quickly and safely. Our professional team will also help with any urgent.

What is the sample fee for Polymethylsilsesquioxane?

Samples up to 1KG are free of charge, and shipping costs are paid on delivery.

For a large amount of sample cost, please contact us to discuss.

What kind of packaging is used for PMSQ?

Resin powder is usually packed in 25KG cardboard drums.

What is the lead time for production?

For our existing regular stock products, we usually need 7-15 days, the lead time may be longer for higher quantities, depending on the actual delivery date of the factory.

For custom products, please contact us to determine the exact lead time.

Do you provide warehousing services for my product orders?

We offer a professional 24-hour monitored warehousing service for every customer.

What are your payment terms?

For samples, 100% T/T in advance.

For orders: 50% TT in advance, 50% balance before shipment.

For large long-term orders, please contact us to discuss payment terms.

How long is the service life of PMSQ?

We use high-standard raw materials to produce silicone MQ resin and VMQ silicone resin, which usually last for 1 year in unopened conditions under indoor ventilation and dry conditions.

I would like to know more?