Silicone pressure sensitive adhesives (often shortened to silicone PSAs) are a small but critical part of the global pressure sensitive adhesive market. Whenever design engineering teams need pressure sensitive tapes that can survive high heat, moisture, sunlight, and aggressive chemicals, silicone pressure sensitive systems quickly become the preferred product category.

Compared with conventional acrylic- or rubber-based PSAs, a silicone heat resistant coating or tape can keep its adhesive properties across an exceptionally wide temperature range, while still offering good tack, cohesive strength, and clean removability from sensitive substrates without leaving residue. For many industrial applications, this combination of adhesion, cohesion strength, and durability simply cannot be matched by other PSA technologies.

- What Is a Silicone Sensitive Adhesive?

- Why Choose Silicone PSAs Over Acrylic or Rubber Systems?

- What is the role of MQ silicone resins in PSAs?

- Typical Applications for High Temperature Silicone Tapes

- Key Design Considerations When Selecting a Silicone PSA

- How to make Silicone Resins Matter in PSA Tapes?

1. What Is a Silicone Sensitive Adhesive?

A pressure-sensitive adhesive is designed to form an instant bond when light pressure is applied. The material is viscoelastic: soft enough to wet the surface and show good wetting characteristics, yet cohesive enough to hold together during use and be removed without destroying the substrate. When coated onto films, plastic films, polyester films, or papers and combined with suitable backings, it becomes the familiar range of tapes and labels used in everyday life.

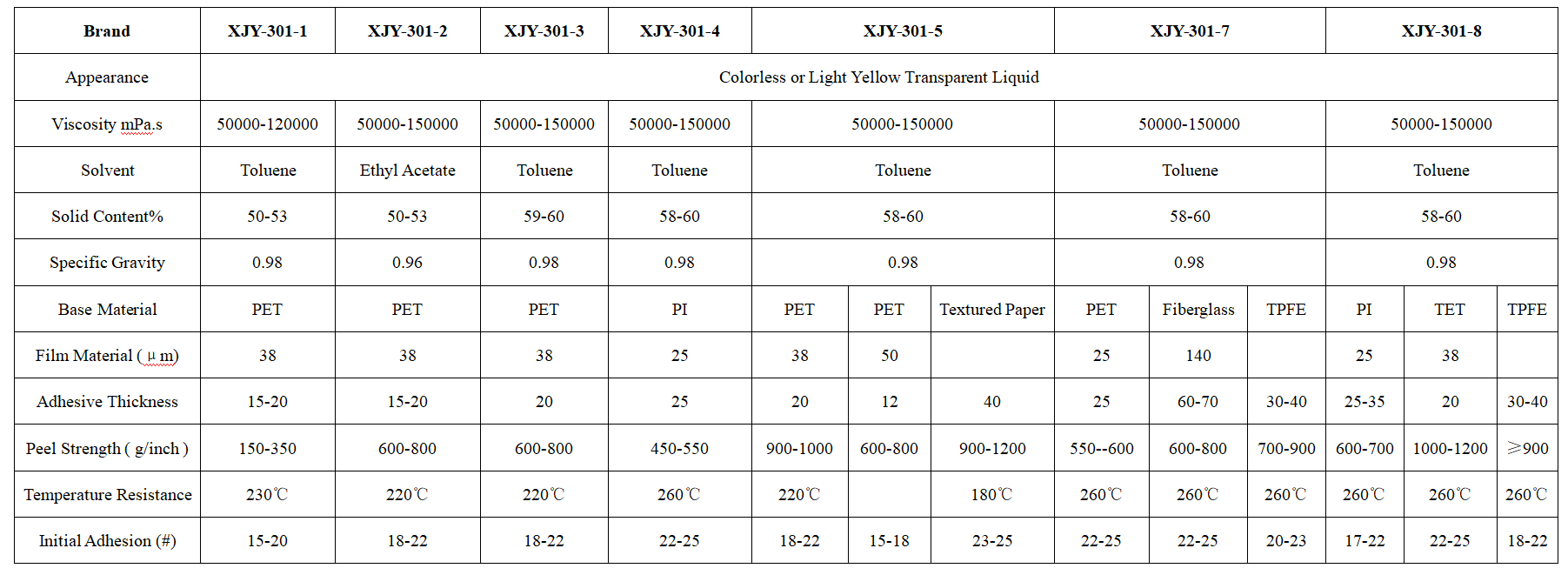

XJY-301 Silicone pressure-sensitive adhesives

It is made from the specific structure of silicone resin and high molecular weight polydimethylsiloxane in cooperation with organic adhesive, which is suitable for specific scene conditions.

Compared with natural rubber, it is characterized by heat resistance, high stability, good electric insulation, good transparency, high peel adhesion, and chemical resistance etc. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care, and mica tapes, splicing tapes, protective films, and other fields.

A silicone pressure-sensitive adhesive uses a silicone polymer backbone instead of a purely organic one. It typically combines:

a high-molecular-weight polydimethylsiloxane (PDMS) or related silicone polymer;

An MQ silicone resin that acts as a reinforcing and adhesion-promoting component within the formulated PSA system.

The Si–O–Si backbone of silicone gives the adhesive outstanding heat resistance and flexibility at both low and high temperatures. At the same time, the dense shell of methyl groups around the chain creates very low surface energy and very good wetting characteristics, allowing the silicone pressure-sensitive adhesive to wet and bond to many low-energy surfaces such as PTFE, fluoropolymers, silicone rubber, coated plastic films, and specialty coated metal surfaces. In practical tape manufacture, these PSAs are usually supplied as solvent-based products, often diluted with aliphatic solvent blends, then coated and cured in modern production sites around the world by manufacturers including global players such as Dow and many regional experts.

2. Why Choose Silicone PSAs Over Acrylic or Rubber Systems?

In standard label and packaging applications, acrylic or rubber PSAs are often chosen first because they are low in cost and easy to process. However, once the design needs high heat, extreme temperatures, long service life, or contact with aggressive chemicals, the difference in performance between silicone PSAs and organic systems becomes obvious.

(1) Wide service temperature range

Silicone PSAs maintain adhesion and flexibility from very low temperatures up to continuous high temperatures and short-term exposure to extreme temperatures. Where acrylic PSAs may become brittle in the cold and soften or flow at high heat, silicone PSAs stay functional, making them ideal for high-temperature tape, high-temperature masking tapes for powder coating, or insulation tapes near engines, ovens, kilns, and industrial furnaces. In these conditions, silicone pressure-sensitive adhesive systems help protect metal surfaces and other substrates without being destroyed by thermal cycling.

(2) Excellent chemical resistance and weathering

Silicone PSAs show superior resistance to oils, solvents, hot gases, mildew, fungus, and industrial contaminants. They also resist moisture, UV, sunlight, and outdoor weathering better than many organic PSAs. This level of chemical resistance and weathering protection safeguards the adhesive bond line in applications exposed to automotive oil, cleaning agents, or continuous moisture, helping to extend the service life of the tape and the components it is designed to protect.

(3) Adhesion to difficult substrates

Because of their low surface tension and very good wetting behaviour, silicone PSAs adhere well to a variety of low-energy substrates where conventional PSAs often fail: silicone rubber, fluoropolymer films, release liners, powder-coated metal surfaces, displays, and specialty coated glass. When a tape must achieve reliable bonding between two “difficult” materials—such as silicone sponge to a painted metal housing—silicone PSAs and MQ silicone resins provide the adhesive strength and anchorage required to meet demanding specifications.

(4) Clean removability and clarity

Well-balanced silicone PSAs can offer strong adhesion during service but still allow clean removability without residue once the job is done. This combination is highly valued in masking tapes for high-temperature coating processes, as well as temporary protection films on stainless steel, glass, and high-clarity displays where optical properties and clean surfaces are critical. Properly formulated systems provide a good set of properties: high peel and tack, high cohesive strength, and clean release from many coated surfaces and backings.

3. What is the role of MQ silicone resins in PSAs?

MQ silicone resins are specialty silicone resins built from M-units (R₃SiO₁/₂) and Q-units (SiO₄/₂). When blended with linear silicone polymers, the resin creates a three-dimensional network that significantly upgrades the adhesive’s mechanical properties.

In a silicone pressure-sensitive adhesive, an MQ silicone resin helps to:

Improve anchorage and cohesion strength – The resin acts as an internal silicone skeleton, so the adhesive resists cold flow and creep under load, increasing cohesive strength and long-term adherence to substrates.

Boost adhesive strength and tack – Adjusting the ratio of silicone polymer to MQ resin allows formulators to fine-tune peel strength, tack, and other adhesive properties for different surfaces, from coated polyester films to metal panels or papers.

Enhance heat resistance and cure behaviour – The highly crosslinked structure of the resin supports the adhesive at high temperature, assists the cure process, and helps it resist deformation and cracking over a wide temperature range.

Increase durability – MQ resins contribute to long-term stability under heat, moisture, sunlight, and biological attack (mildew or fungus), helping the adhesive system meet the most demanding industrial applications.

By choosing the right MQ silicone resin grade and ratio, and combining it with appropriate fillers and pigments, formulators can discover a wide variety of silicone PSAs—from ultra-soft, repositionable PSA tapes to very firm, high-strength masking tapes—each designed to meet a specific request from OEM customers.

4. Typical Applications for High Temperature Silicone Tapes

Thanks to the combination of adhesive strength, cohesive strength, heat resistance, and chemical resistance, silicone PSAs are used in many demanding applications where standard PSAs are quickly destroyed. Common examples include:

High temperature masking tapes for powder coating, e-coat, and other industrial coating processes on metal surfaces, where tapes must remain in contact with the substrate through the cure cycle and then remove cleanly.

Electrical and electronic insulation tapes, often based on polyimide or polyester backings and plastic films, are used in motors, transformers, coils, and printed circuit board manufacture. Here, silicone PSAs provide high dielectric strength, good wetting characteristics, and clean removability without residue.

Industrial and automotive tapes near engines, exhaust systems, kilns, heat exchangers, and industrial furnaces, where substrates may be exposed to oil, moisture, fumes, and fluctuating temperatures. Silicone PSAs protect sensitive components and maintain adhesion even after repeated heating and cooling.

Temporary protection films and papers on stainless steel, aluminium, glass, and electronic displays, which must be kept clean and scratch-free during fabrication and shipping. After delivery, the PSA film needs to peel away quickly without leaving adhesive content on the surface.

Specialty applications such as splicing tapes, labels, and bonding tapes for photovoltaic modules, where clarity, weathering resistance, and long-term performance are essential results of using silicone PSA technology.

In all these applications, the right combination of adhesive, backing, coating weight, and cure conditions enables silicone pressure-sensitive tapes to offer consistent performance, even when supplied from different production sites around the world.

5. Key Design Considerations When Selecting a Silicone PSA

When engineers and buyers evaluate a silicone PSA or high-temperature tape, several technical and practical factors should be considered to achieve the desired results and ensure the product will meet performance targets.

Operating temperature and environment – Define the continuous and peak temperatures, plus exposure to moisture, sunlight, mildew, fungus, oil, or industrial solvents. This helps determine the level of heat resistance and chemical resistance required from the PSA system.

Substrate type and surface energy – Identify whether the tape will be applied to steel, aluminium, glass, plastics, coated films, silicone rubber, or other low-energy surfaces. Different MQ resin levels and filler packages can be used to optimize adhesion and improve anchorage for each substrate.

Required adhesion, tack, and removability – Decide if the bond should be permanent or removable, and whether clean removability is critical. The polymer/resin ratio, solids content, curing conditions, and any addition of crosslinkers can be tuned so that the adhesive will set to the right balance of tack, peel, and shear.

Coating and converting process – Consider whether the silicone PSA will be coated as a solvent-based product, how it will be diluted, what kind of backings (films, papers, foams) will be used, and the overall manufacturing route. Proper process design helps minimise defects, improve clarity, and make the adhesive easier to use in high-speed industrial lines.

Working closely with a silicone PSA supplier and technical expert allows formulators to fine-tune details such as coating weight, cure temperature, and solvent choice (for example, aliphatic vs. aromatic) so that the final PSA tape is truly fit-for-purpose.

6. How to make Silicone Resins Matter in PSA Tapes?

As industries move toward higher performance, longer service life, and stricter environmental regulations, silicone pressure-sensitive adhesive systems based on MQ silicone resins are becoming more important than ever. They enable pressure-sensitive tapes and films that stay stable at high temperatures, resist moisture, mildew, fungus, and chemicals, bond low-energy surfaces, and still offer clean removability without residue when required.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone PSA field and support the provision of diversified customized solutions.

![]()