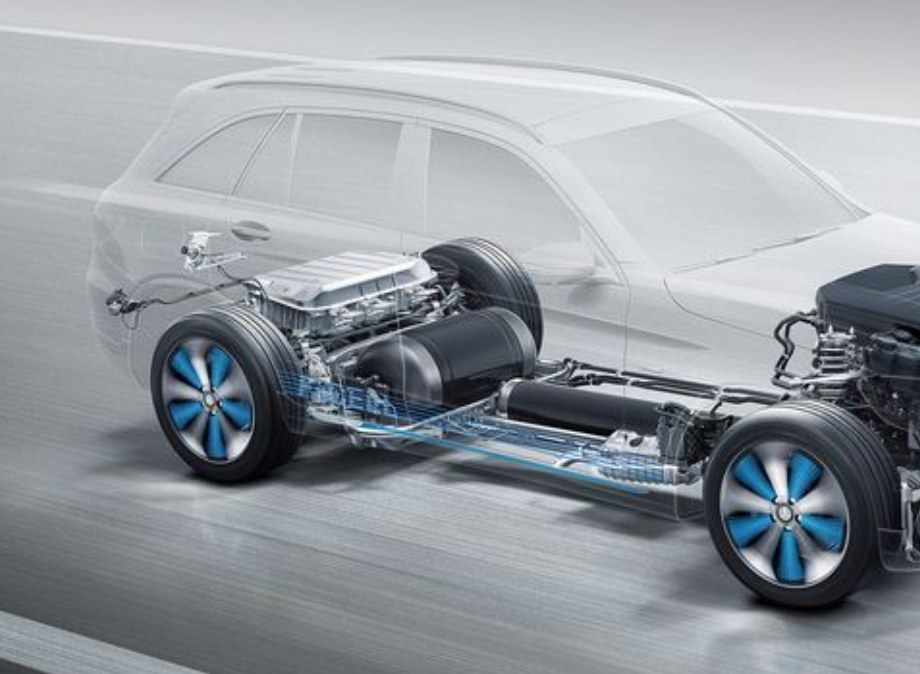

In recent years, the global market for new energy vehicles has continued to grow at a rapid pace, with the electric vehicle (EV), hybrid electric vehicle (HEV/PHEV), commercial electric truck, and urban rail transit sectors expanding continuously. According to a report by the International Council on Clean Transportation, global EV sales exceeded 16 million units in 2023, with the Chinese market maintaining its leading position, accounting for more than half of the global total.

Electric vehicle batteries, as core components, directly determine the performance, safety, and durability of the entire vehicle. Battery modules are increasingly developing toward higher energy density, faster charging, and greater intelligence, while also facing stricter environmental and safety challenges. Silicone can meet the electrical insulation requirements under high-voltage and high-current operations; extreme temperature changes, impacts, water exposure, and chemical corrosion; VE/EMC requirements and an 8-year/100,000-kilometer lifespan guarantee; and lighter-weight and higher cost-effectiveness material standards. In addition, as the demand for “car silicone” in the industry grows, automotive manufacturers are focusing more on using silicone materials for their excellent temperature resistance and reliable long-term protection.

There are seven aspects to introducing silicone resin:

- Why do electric vehicle batteries require silicone?

- What are the properties of silicone resin materials?

- What are the advantages of silicone resin in electric vehicle battery applications?

- What are the applications for silicone resins in power batteries?

- What is the value of silicone resin for electric vehicle powertrain systems?

- What is the application results analysis of car silicone?

- How to improve silicone applications for better performance in electric vehicles?

1. Why do electric vehicle batteries require silicone?

An electric vehicle battery system primarily consists of individual battery cells (cylindrical, prismatic, pouch), modules/packs (composed of multiple cells), a battery management system (BMS), high-frequency connectors, terminals, busbars, structural components of the cooling system, and housings. Each component requires high-performance materials to ensure system insulation safety (preventing short circuits, leakage, and creepage), structural stability (withstanding vibration, impact, and thermal expansion/contraction), and environmental protection (waterproofing, dustproofing, corrosion resistance, and flame retardancy/heat resistance). For these various parts, high-performance silicone materials are ideal, especially considering their compatibility with metal and plastic surfaces in the battery housing and electronic components.

Traditional materials such as epoxy resin and polyurethane (PU) tend to yellow, crack, absorb moisture, and age in high-temperature and high-humidity environments, leading to a decline in insulation performance and potentially causing thermal runaway or short circuits and fires. In addition, moisture intrusion into auto parts can lead to issues such as corrosion or even damage to sensitive electric or electronic components. Additionally, their sealing and mechanical protection properties are difficult to balance, limiting the battery system's longevity and high safety standards. Furthermore, these materials are heavy and have complex manufacturing processes, which are not conducive to automated production and sustainable manufacturing. Therefore, there is an urgent need for new silicone resins and silicone sealants that achieve breakthroughs in “safety, durability, lightweight, and environmental friendliness.” For instance, durable silicone products have been widely used in automotive applications ranging from interior parts, auto parts, to oil pans and even noise reduction accessories.

2. What are the properties of silicone resin materials?

Silicone resins are a class of high-molecular-weight materials with a Si-O-Si backbone structure, supplemented by organic side groups such as methyl, phenyl, and vinyl. The main chain is highly cross-linked, forming a three-dimensional network structure that confers the material with unique “rigid yet flexible” properties and strong resistance to vibration and cracks.

This class of materials exhibits multiple outstanding properties: high dielectric resistivity up to 10¹⁵ Ω·cm, resistance to extreme temperatures (-60°C to +250°C or higher) without deformation or aging; excellent flame-retardant performance, meeting UL94 V-0 standards, and passing flame-retardant certifications for automotive electronics in multiple countries; low water absorption and low moisture absorption, resistant to water vapor corrosion; adjustable mechanical properties, capable of achieving flexibility or rigidity, suitable for complex shape molding, dispensing, and potting, such as sealing windshields or auto electrical surfaces. Simultaneously, silicone materials are resistant to ultraviolet rays, ozone, and chemical corrosion, without yellowing or decomposition; low surface energy, with self-cleaning and anti-pollution properties—making it easy to clean and maintain details of automotive surfaces. Silicone materials can also be processed into environmentally friendly products with extremely low VOCs, free of heavy metals and halogens, meeting high safety and sustainable manufacturing requirements. These characteristics make silicone suitable for protecting a wide variety of car categories and forms, providing reliable protection for the vehicle engine, tires, oil pans, and other crucial components.

3. What are the advantages of silicone resin in electric vehicle battery applications?

(1) Electrical Insulation and Safety Assurance

High insulation performance effectively blocks high-voltage current leakage and prevents internal short circuits

Excellent creepage resistance and arc resistance, particularly suitable for high-voltage fast charging and high-current discharge scenarios

Strong breakdown resistance ensures long-term structural safety of the battery pack, protecting it from issues such as damage from gas build-up and ensuring the reliability of critical electronic components and rubber-based parts.

(2)Superior Heat Resistance and Flame Retardancy

Can withstand long-term exposure to battery operating or abnormal heating temperatures, preventing failure caused by high-temperature aging or shrinkage of structural parts

Leading flame retardancy rating (UL94 V-0), effectively containing thermal runaway spread and enhancing vehicle battery accident safety factors in all weather conditions.

Does not release harmful gases, protecting the occupants and rescue personnel's safety. The strong temperature resistance and protection features also reduce the risk of cracks or other forms of damage occurring inside the engine bay and other auto parts.

(3) Excellent Mechanical Protection and Sealing Defense

Strong vibration and impact resistance, suitable for daily road conditions and accident environments of electric vehicles

Flexible or rigid options available, compatible with wedge-shaped/curved/non-standard structural designs—ideal for a variety of accessories and ensuring width adaptability

Excellent sealing performance, effectively preventing dirt, dust, water, and salt fog ingress, suitable for complex usage scenarios such as water immersion, high humidity, and coastal environments. The sealant properties of car silicone have made it a product of choice for protection against moisture and oil in oil pans and other exposed categories of automotive components.

(4) Chemical stability and resistance to environmental corrosion

Resistant to acid-alkali corrosion and oil-based chemical contamination; silicone resin remains unaffected by electrolyte or road solutions over the long term

Resistant to UV radiation, ozone, and other environmental aging elements, extending the service life of the vehicle battery system and ensuring strong durability against noise, extreme weather, and routine wear.

(5) Lightweight and design flexibility

Adjustable molecular weight, lower density than traditional epoxy or PU, offering significant weight-saving advantages—beneficial for interior parts, engine covers, noise-dampening panels, and various forms of auto accessories

Supports various processes such as injection molding, coating, and potting, compatible with automation, and meeting manufacturers’ needs across various parts and product width requirements

Customizable performance based on spatial structure and mechanical requirements, enabling modular design and strong reliability across a variety of car forms and dimensions

(6) Environmental sustainability and regulatory compliance

Halogen-free, low VOC, and free of harmful plasticizers, meeting regulatory requirements for exports to Europe, the US, Japan, South Korea, and new energy vehicles

Compliant with RoHS, REACH, UL, and automotive electronics AEC-Q200 certification standards; supports recycling, enhancing environmental sustainability throughout the entire lifecycle—fitting Ford’s global environmental review standards and requirements for prepared auto parts manufacturers.

4. What are the applications for silicone resins in power batteries?

(1) Battery Module Encapsulation

Used for encapsulation protection between individual cells and modules, enhancing overall insulation and impact resistance—especially crucial in car applications where strong sealing is required.

Serves as a sealing material for module housings, achieving waterproofing, dustproofing, and corrosion resistance—protects surfaces and electronic components from moisture and environmental elements, and keeps automotive accessories clean and operational for a longer life.

Flame-retardant coating enhances safety redundancy and prevents fire spread in the vehicle.

(2) Battery Management System (BMS) Protection

Encapsulation of BMS circuit boards and integrated circuits, enhancing electrical insulation, moisture resistance, and chemical resistance

Effectively isolates external interference, improving the stability and reliability of BMS sensor detection—ideal for use in automotive electronic components

Flame-retardant silicone resin ensures the BMS system remains functional during thermal runaway; sealing properties protect against gas, vapor, and oil ingress at connection points

(3) Battery Terminals and Connection Point Insulation Sealing

Used for coating and dispensing on high-voltage terminals and connectors to prevent corrosion, tracking, and short circuits at connection points; also suited for vibration-prone auto parts, tires, and suspension-related categories

Flexible material adapts to thermal expansion and contraction, ensuring uniform stress distribution over the long term and preventing delamination, damage, or functional decline of automotive components

(4) PCB and electronic component encapsulation

Encapsulation and isolation for electronic control boards, sensor components, and power chips requiring precise control

Prevents moisture, dust, and salt fog intrusion that could cause electric failure, noise issues, or shortened product life

Ensures reliable electronic system performance under long-term high-temperature, high-humidity, and complex environmental conditions—also protecting interior parts and adding design value for automotive manufacturers

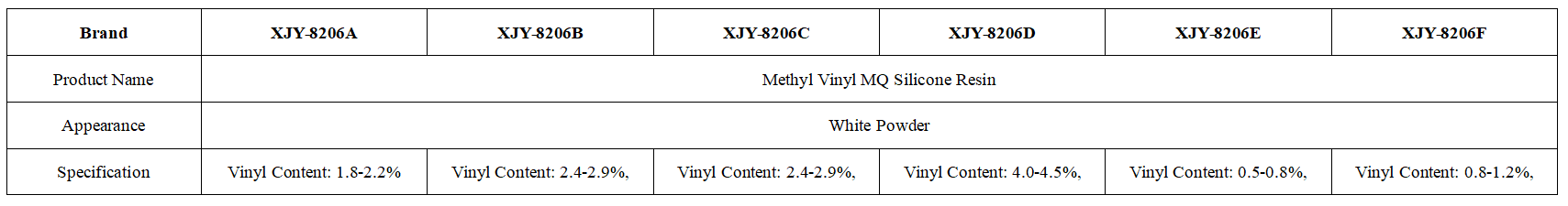

XJY-8206 Powder series methyl vinyl MQ silicone resin can be used to manufacture highly transparent and high-hardness VMQ silicone rubber, RTV silicone, and other LSR.

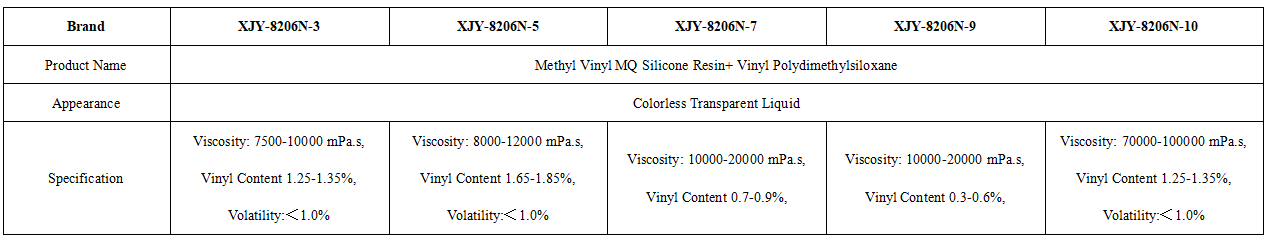

XJY-8206N Solution series methyl vinyl MQ silicone resin + vinyl polydimethylsiloxane can be used to make a two-component sealant.

(5) Thermal management and flame-retardant layer

Serves as a thermal interface material for battery packs to improve heat dissipation efficiency

Nano-filled silicone resin enhances thermal conductivity, assisting the battery module temperature control system and keeping the engine bay cooler

Flame-retardant layer isolation reduces the risk of thermal runaway propagation between components and allows for easy maintenance and repairs—ideal for a variety of auto parts and accessories where heat and gas management is critical

5. What is the value of silicone resin for electric vehicle powertrain systems?

(1) Enhances safety and longevity

Silicone resin used in battery packs and structures improves system insulation, reducing the risk of fire or explosion—an important detail for every car, automotive category, and application

Superior aging resistance supports the vehicle's “8-year/100,000-kilometer” lifespan guarantee, ensuring strong durability and reliability in all forms of electric automobiles and hybrids

Equivalently enhances battery module durability, positively supporting OEM manufacturing and brand reputation, and making it easier for manufacturers to pass global reviews and maintain long-lasting product life and protection for all car categories

(2) Reducing maintenance and quality risks

Long-term resistance to cracking and degradation reduces maintenance costs and after-sales risks—providing peace of mind for users and increasing the reputation of silicone product applications in car and battery systems

Rapid repair and re-coating capabilities support long-term maintenance throughout the battery lifecycle, keeping accessories, rubber components, and high-temperature auto parts protected

(3) Supporting OEM/ODM factory technology upgrades and differentiation

Compatible with various battery structures (cylindrical, prismatic, pouch, blade, etc.) as well as electronic and structural parts

Supports automated potting/coating/injection molding, improving production efficiency and quality consistency across a variety of manufacturers and global accessories suppliers

Customizable formulations provide OEMs with unique process advantages and premium product branding, supporting easy integration into all relevant car, automotive, and battery forms

(4) Meet global new energy regulations and access premium markets

Halogen-free flame-retardant/low-VOC products can easily pass global mainstream automotive electronics standards and review for Ford-class and other premium applications

Assist customers in gaining recognition in regions such as Europe, the Americas, Japan, South Korea, and the Middle East, as well as automotive categories related to engine, oil, and tire management

Support export compliance certification, enhancing international cooperation capabilities, and allowing a variety of silicone sealants and auto parts to be prepared for distribution to a global market

6. What is the application results analysis of car silicone?

Case Study 1: Domestic new energy passenger vehicle battery modules

A leading new energy vehicle manufacturer adopted silicone resin for battery module encapsulation, reducing insulation breakdown rates by 90%, thermal runaway incident frequencies by 60%, and vehicle failure repair rates by 30% year-over-year; obtained European UL and RoHS certifications, successfully exporting to the German and North American markets. This demonstrates the strong product performance and details that car silicone brings to automotive battery reliability and safety.

Case 2: Electric Bus and Truck Battery Systems

A large OEM factory applied organic silicon flame-retardant coatings to battery packs for electric commercial vehicles operating in extreme cold, high temperatures, and heavy loads, significantly improving temperature cycle endurance and noise isolation. After accidents, the coatings enable rapid sealing and repair, supporting the full lifecycle safety management of battery packs for autonomous driving, public transport, and various vehicle categories, as well as ensuring strong durability under vibration and difficult weather conditions.

Case 3: Application of Organic Silicon Resin Solutions in ODM Battery Factory Automated Production Lines

A globally renowned ODM battery equipment company has adopted Jiangxi Xinjia Yi's silicone resin solution, achieving a qualified rate of 99.8% on automated dispensing/encapsulation/coating production lines, shortening product delivery cycles, and enhancing customer loyalty through technological differentiation. Such car silicone applications help clean production processes, reduce issues, and make it easy to achieve global compliance for a variety of automotive accessory product categories.

7. How to improve silicone applications for better performance in electric vehicles?

Innovations in encapsulation and protective materials are driving significant upgrades in battery performance and safety. Silicone resins, with their unique molecular structure and superior performance, are increasingly becoming the preferred choice for global battery manufacturers and OEM/ODM factories. Compared to traditional materials, silicone resins excel in multiple performance metrics: Their insulation performance is exceptional (>10¹⁴Ω·cm), far surpassing epoxy resins (approximately 10¹³Ω·cm), polyurethanes (which degrade due to moisture absorption), and acrylics (which migrate easily); they have a wide temperature resistance range (-60°C to 100°C); they are environmentally friendly, halogen-free, and have low VOC emissions; they offer good process compatibility and support automated production, whereas traditional materials have limitations in terms of environmental friendliness and process adaptability. In addition, using high-performance car silicone products ensures that auto parts and surfaces are protected, reduces noise, vibration, and shrink problems, and delivers a variety of benefits for automotive applications—helping manufacturers maintain easy compliance, safety, and product reliability across all car forms and categories. How can product competitiveness be enhanced?

XJY Silicones is one of China's leading manufacturers of silicone MQ resins and VMQ silicones, with over 30 years of R&D and manufacturing experience in the organic silicon industry, as well as over 15 related patents and technical support. Our silicone raw material products can meet the needs of the car field and support the provision of diverse customized solutions.