With the rise of green building materials and high-performance coatings, improving the hydrophobicity, adhesion, and long-term performance properties of traditional materials has become a challenge. Especially in wood protection, achieving a “lotus-leaf effect” for durable, waterproof, and anti-fouling surfaces is essential. What are the advantages of silicone resin in waterproof coatings?

In the field of functional coatings and surface protection materials, silicone resins have become indispensable binders and film formers. Their unique siloxane backbone (Si–O–Si), combined with organic side groups, offers both the stability of inorganic compounds and the flexibility of organic polymers for a waterproof field. Whether used in pressure-sensitive adhesives, release agents, mold making, or heat-resistant coatings, silicone resin systems consistently deliver reliable performance and durability.

- Why Choose Silicone Resin?

- Innovative Applications in Wood Waterproofing and Anti-Fouling

- Simple Process for Making Silicone Resin Coatings

- Mechanism of Waterproof and Anti-Fouling Performance

- Extended Typical Applications

- Future Development and Industry Trends

1. Why Choose Silicone Resin?

(1) Unique Chemical Structure and Features

Silicone resins have a robust Si–O–Si network with exceptional thermal and chemical stability. Organic functional groups such as methyl, phenyl, or fluoroalkyl can be added to modify hardness, color, and flexibility, depending on the type and mix ratio.

This combination allows the resin to withstand extreme weather, UV light, and humidity while maintaining excellent film formation and adhesion.

(2) Outstanding Waterproof and Weather Resistance

Thanks to their low surface energy, silicone resins form a clear, dense film that protects surfaces from water, wax, dirt, and pollutants.

Unlike conventional coatings, these films resist cracking and fading, even under heat or outdoor weather conditions. Silicone coatings are also compatible with various substrates and safe for long-term use.

(3) Excellent Heat and Chemical Resistance

With strong Si–O bonds, silicone resins maintain stability under heat and chemical stress. They are ideal for high-temperature coatings, two-part epoxy systems, and industrial encapsulation materials that require resistance to extreme thermal cycling.

(4 )Superior Adhesion and Compatibility

Silicone resins adhere well to wood, metal, ceramics, glass, and concrete, forming durable films that resist peeling. Their economical curing process and easy application make them suitable for both small-scale and large-scale production settings.

(5) Fast Curing and Environmental Safety

Modern formulations can cure quickly at room temperature or under mild heat, allowing efficient production without compromising safety.

Low-VOC or solvent-free systems meet industry standards for environmental protection, making silicone resins a sustainable choice.

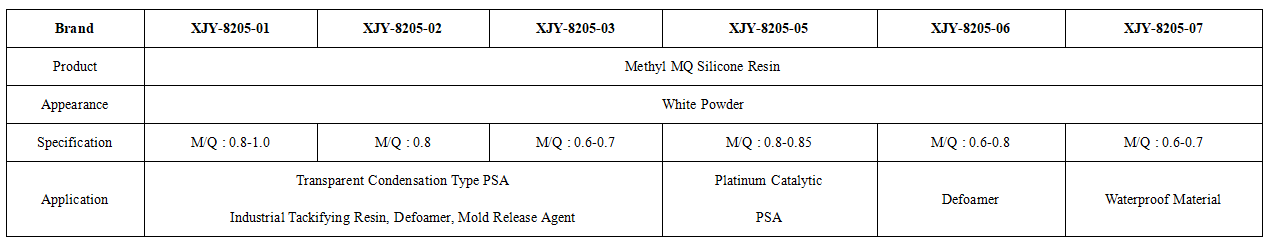

XJY-8205 MQ resin(Silicic acid, sodium salt, reaction products with chlorotrimethylsilane and iso-Pr alc..) is a co-hydrolysis product of tetraalkoxy silane (Q unit) and trimethylalkoxy silane (M unit).

MQ resin is widely used in waterproofing agents, and with good high demolding power in release agents for polyurethane processing.

2. Innovative Applications in Wood Waterproofing and Anti-Fouling

Natural wood is beautiful but prone to swelling, cracking, and mold growth due to moisture. By integrating silicone resin chemistry, manufacturers can develop coatings that create a water-repellent, self-cleaning surface.

The coating forms chemical bonds through dehydrogenation reactions, generating a highly durable silicone network. The result is a flexible yet strong protective film with superior waterproof and anti-fouling properties.

This innovation continues to expand into other applications, offering flexibility, long-lasting protection, and excellent weather resistance—essential for furniture, decking, and outdoor architectural elements.

3. Simple Process for Making Silicone Resin Coatings

Producing silicone-based coatings is straightforward and cost-effective. Below is a simplified guide to help you understand the general process (details may vary depending on product content and desired properties):

(1)Surface Preparation

Clean and dry the substrate to remove oil, dust, or contaminants. Smooth, dry surfaces ensure uniform coating adhesion.

(2) Mixing the Solution

Combine the silicone resin or hydrogen silicone oil with a vinyl siloxane resin and nano silica filler. Adjust viscosity by adding compatible solvents. A catalyst may be used to speed up the cure reaction.

(3)Application Method

Apply the coating through spraying, dipping, or brushing, depending on the product type and settings. The coating mixture should form a uniform layer on the surface.

(4) Curing and Film Formation

Allow the resin to cure under ambient temperature or mild heating. Once cured, the resin forms a durable, weather-resistant film.

(5) Final Check

Inspect the coating for clarity, gloss, and hydrophobicity. A properly applied silicone resin layer offers long-lasting protection and ease of maintenance.

This method requires no complex tools—just a variety of compatible ingredients and simple two-part systems—making it ideal for industrial production.

4. Mechanism of Waterproof and Anti-Fouling Performance

Silicone resins exhibit superior protection through both chemical and structural mechanisms:

Low Surface Energy Barrier

Hydrophobic groups minimize surface tension, preventing water or oil from wetting the surface. Droplets roll off easily, carrying dirt away.

Micro/Nano Structure Enhancement

The inclusion of silica creates a rough, layered structure that traps air pockets, reducing liquid contact and improving self-cleaning ability.

Strong Chemical Bonding

The Si–H and Si–O–C linkages provide firm adhesion, forming a flexible yet robust coating that maintains integrity in changing environments.

5. Extended Typical Applications

Silicone resin technologies are widely used across multiple sectors and industries due to their versatility and performance properties:

(1)High-Temperature Coatings

Methyl and phenyl silicone resins withstand temperatures above 300°C, commonly used in engine coatings, exhaust systems, and heat-resistant paints.

(2)Construction Waterproofing

Silicone resins and silane-based agents are applied to concrete and stone surfaces, protecting against moisture ingress while maintaining breathability.

(3) Release Agents and Defoamers

The low surface energy and chemical inertness make silicone resins perfect release agents and additives for rubber, plastic, and epoxy mold applications.

(4) Encapsulation and Adhesives

In electronics, silicone resin-based encapsulation materials provide insulation and protection against moisture and heat, often combined with epoxy systems for enhanced strength.

(5) Automotive and Aerospace Coatings

Silicone resin coatings protect vehicles and aircraft from UV light, salt spray, and pollution, offering lightweight, long-term protection with minimal maintenance.

6. Future Development and Industry Trends

As environmental standards evolve, silicone resins continue to drive innovation in modern coating technology. Key directions include:

Green Production: Development of low-VOC and water-based silicone formulations that are safer and more sustainable.

Multifunctional Systems: Integration of waterproofing, corrosion resistance, heat resistance, and self-cleaning into one product.

Smart Materials: Research into self-healing and temperature-responsive silicone hybrid resins for next-generation coatings.

Manufacturers in the Netherlands, Europe, and Asia are leading this movement, enhancing silicone resin technology with advanced testing, data monitoring, and flexible mix designs to ensure consistent quality and performance.

How to make waterproof performance better?

Silicone resin is not just a coating ingredient—it’s a high-performance binder that enables superior waterproofing, anti-fouling, and thermal stability across industries.

Its flexibility, fast curing, and broad range of compatible materials make it an ideal solution for both traditional and advanced industrial coatings.

As a professional silicone resin manufacturer, we provide tailored raw materials for:

Wood and architectural waterproof coatings

High-temperature industrial paints

Release agents, defoamers, and making molds products

Electronic encapsulation and adhesives

Our products are designed to deliver reliable performance, ease of use, and long-lasting durability—helping customers around the world choose the right product, achieve better results, and continue improving their production quality. Any weight or note, please view our web.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone waterproof field and support the provision of diversified customized solutions.

![]()