Chemical processing detergents play a vital role in daily life. However the production of foam often accompanies the cleaning process, this unwanted foam not only affects the cleaning effect but also may lead to equipment failure and even environmental pollution. Thus, the cleaning agent defoamer came into being, and silicone defoamers are indispensable. What is the washing silicone defoamer?

Silicone detergent defoamer is a Polyether-modified silicone defoamer. Compared with the traditional defoamer, it can maintain good stability in the system coexist with various additives for a long time in various industries, and does not react with other substances. Its high-temperature performance is excellent and is suitable for use in laundry detergent, laundry powder, cleaning agents, printing pulp, bleaching, dyeing, refining, all kinds of fiber with oil, papermaking, mechanical cutting, and other projects to control foam.

There are seven aspects for introducing silicone defoamers in washing:

- What is silicone defoamer?

- What is the silicone defoamer?

- Why do you need to defoam in washing?

- What cause foam in washing?

- What are the features of defoamer in washing?

- Why choose silicone defoamer in washing?

- How to make silicone defoamer performance better?

1. What is silicone defoamer?

Silicone-based defoamers are a powerful assistant in washing solutions, which can effectively eliminate excessive foam. They play an important role not only in the detergent but also in the cosmetic, food processing, and pharmaceutical industries. They are widely used in a wide range of applications, such as chemical, textile, cutting oils, food, etc., to provide an effective solution to the adverse effects of air bubbles on the production process and product quality.

Different from mineral oil defoamers, silicone defoamers eliminate foam in three main ways.

First, it has very low surface tension, making it difficult for the foam to form in a low surface tension environment. Secondly, it destroys the foam film and finally, disperses the foam, thus reducing the amount of foam.

2. What is the silicone defoamer?

There are many types of silicone defoamers with its characteristics. There are many types of silicone defoamers, including silicone oil type, emulsion type, solution type, and polyether modified type.

(1) Silicone oil-type defoamer with Polysiloxane as the main component has temperature resistance and chemical resistance and forms a uniform film layer on the surface of the liquid, hindering the formation and stabilization of air bubbles.

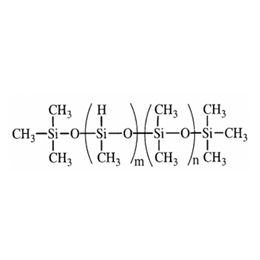

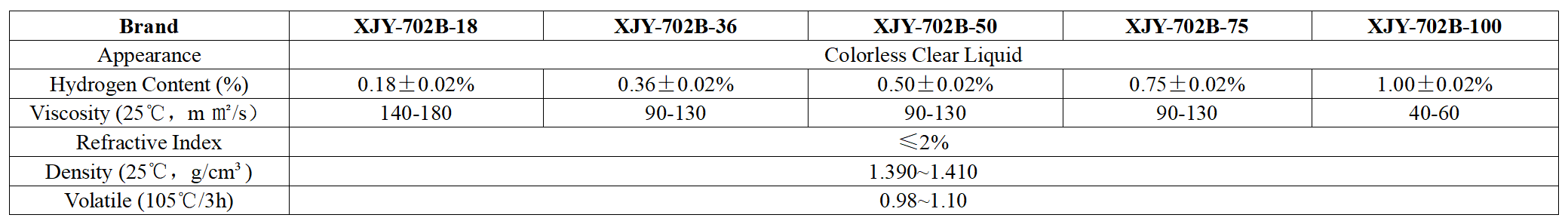

XJY-702 Methylhydrosiloxane/Dimethylsiloxane Copolymer is non-toxic and odorless, containing active Si-H groups. It can react with a double bond and hydroxyl groups under the action of a catalyst and is used as the basic raw material of foam stabilizers, antifoam agents, water-soluble silicone oil, and other products.

(2) Emulsion-type antifoam agent is the incarnation of silicone oil-type antifoam agent, which is made into an emulsion by an emulsifier, easy to disperse in liquid, and capable of rapid defoaming.

(3) Solution-type antifoam agent is dissolved silicone compound in solvent to form solution-type antifoam agent, which is suitable for the antifoam demand of solvent liquid.

XJY-8205 Powder Series Methyl MQ Silicone Resin is a solid food-grade powdered reactive silicone resin. The resin has excellent transfer resistance and water resistance, forming a long-lasting film, which is one of the raw materials of silicone emulsion antifoam agents in aqueous systems and can be used in food processing, coatings, water treatment, pulp and paper, metalworking fluids and other industrial applications for foam control.

(4) Polyether-modified defoamer is based on polyether-modified silicone compounds with a certain degree of high-temperature resistance and can be effectively defoamed in high-temperature environments.

These silicone defoamers can prevent the formation and stabilization of bubbles by forming a film on the surface of the liquid to eliminate bubbles. They are widely used in various industrial fields, such as chemical, textile, paper, food, etc., to solve the adverse effects of air bubbles on the production process and product quality.

3. Why do you need to defoam in washing?

In the industrial cleaning process, foaming is mainly due to the surface tension of water, when the mutual attraction between water molecules is stronger than the attraction between water molecules and air, bubbles will be formed and gathered to become foam.

The creation of foam may cause the cleaning equipment to run slowly or even shut down, as it may trigger the equipment's overflow sensor or cause mechanical failure. In addition, the foam carries away a portion of the cleaning agent, resulting in increased usage and potentially increased costs by increasing the number of cleaning cycles.

4. Why cause foam in washing?

Detergent foam may also be due to the surfactant in the product easily reacting with other reagents, degreasing agent in the proportion of chemicals and water deviation, and the temperature environment, these are the factors that lead to foam, foam for multi-void cleaning products such as fiber products foam is not easy to rinse clean, need to extend the rinse time, add rinsing costs, too much foam will even affect the lubricating effect of the machine to reduce the rubbing strength, instead of affecting the cleanliness. Strength, but affect the cleanliness, etc.

5. What are the features of defoamer in washing?

The anti-foaming agent plays an important role in washing, it is mainly used to reduce the foam generated during the washing process and to improve the washing effect and efficiency. The following are

(1) Reduce foam:

During the washing process, detergents such as laundry detergents are prone to produce a large amount of foam, and excessive foam will affect the washing effect and even lead to overflow of the washing machine. Adding the right amount of defoamer can effectively reduce the foam and maintain the stability of the washing process.

(2) Improve the washing effect:

Adding a defoamer can help the detergent to better contact the dirt and improve the washing effect. While reducing the foam, the defoamer will not affect the washing performance of the detergent but can enhance the cleaning effect.

(3) Preventing washing machine malfunction:

Excessive foam can lead to washing machine malfunctions, such as foam overflow and drain clogging. Adding a defoamer can effectively prevent these problems and protect the normal operation of the washing machine.

Antifoam agents are used in different types of washing, including home laundry, industrial washing, dishwashing, and so on. There are many types of defoamers, so you can choose the right product for different washing scenarios.

(5) Environmental friendliness:

Modern defoamers are usually environmentally friendly and will not pollute the water quality and the environment, in line with the requirements of greenwashing.

6. Why choose silicone defoamer in washing?

In general, the application of silicone defoamer in washing helps to improve the washing effect and protect the washing machine and the environment, it is an indispensable part of the washing process.

(1) Foam removal

During the washing process, detergents will interact with water molecules to form foam. Although foam visually gives a feeling of cleanliness, too much foam may cause some problems. For example, when washing clothes in a washing machine, if there is too much foam, it may cause the top of the washing machine to overflow or even interfere with the normal operation of the washing machine. In addition, too much foam can also lead to incomplete detergent removal and an increased likelihood of detergent residue on the clothes. Therefore, the role of washing silicone antifoam agents is to help control the generation of foam by regulating the foam generation of the detergent to ensure the normal operation of the washing machine and the improvement of the washing effect.

(2) Improvement in permeability and diffusivity

Foam in the detergent will reduce the contact area between the detergent and the dirt, affecting the permeability and diffusivity of the detergent, thus reducing the cleaning effect. Washing silicone defoamer can effectively reduce foam generation, increase the contact area between the detergent and the dirt, and improve the cleaning effect. Whether washing clothes, washing dishes, or cleaning the home, washing defoamer can help the detergent play a better role.

(3) Anti-static ability

In the washing process, the fiber surface easily accumulates static electricity, resulting in clothing or other items adsorbed dust and dirt. Washing silicone defoamer in the active substances can neutralize or reduce the generation of static electricity, effectively preventing the clothing adsorption of dust and dirt, to keep things clean and tidy.

7. How to make silicone defoamer performance better?

Silicone detergent defoamer plays a role in removing foam, improving detergent penetration and diffusion, and anti-static during the cleaning process. It can help to control the generation of foam, ensure the normal operation of the washing machine, improve the cleaning effect, and prevent the items from absorbing dust and dirt. In our daily lives, the correct use of washing defoamer can better utilize the function of detergents and make our lives cleaner and more comfortable. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the defoamer field and support the provision of diversified customized solutions.