Since its inception, silicone materials have been widely used in medical, light industry, cosmetics, and other fields for their excellent viscoelasticity, stability, and waterproofness. Silicone resins, modified silicone oils, silicones for washing, and powder treatments have developed rapidly in the cosmetics field. Among them, MQ silicone resins are used in many cosmetic applications and are usually used to form films to increase waterproofing and makeup-holding effects.

MQ silicone resin is a copolymerization product of tetraalkoxysilane (Q-unit) and trimethylethoxysilane (M-unit). Its excellent waterproofing and make-up-holding ability have led to its wide application as a film-forming material in the cosmetic field, and it is therefore very important to evaluate and select suitable MQ film-forming agents to improve the efficiency of formulation development.

There are six aspects to introducing mq silicone resin:

- What are MQ silicone resins?

- What affects the performance of MQ silicone resin?

- What are the film-forming agents?

- How to choose the film-formers?

- Why choose silicone film-forming agent?

- How to make silicone film-forming agents?

1. What are MQ silicone resins?

MQ silicone resin is a copolymerization product of functional groups: tetraalkoxysilane (Q unit) and trimethylethoxysilane (M unit). Generally speaking, it has a special double-layer tightly cross-linked spherical network structure, which makes it not only excellent in water resistance, thermal stability, and compatibility, but also long-lasting, safe, and non-irritating, and can improve the mechanical properties of products. Thus, it becomes one of the indispensable ingredients in color cosmetic formulations. However, due to the structural diversity of the hydrolyzed polycondensation products of functional silicone derivatives, the MQ silicone resins have different properties, which makes the screening and debugging in the formulation application very difficult. Taking trimethylsiloxysilicate as an example, different M/Q composition ratios can form different soft and hard silicone films.

2. What affects the performance of MQ silicone resin?

MQ silicone resin's film-forming property, film-forming time, hydrophobicity, perspiration and oleophobicity, air permeability, molecular weight, distribution status, and other properties of the intrinsic connection. The results show that the properties of MQ silicone resin are related to its molecular weight and distribution state. For MQ silicone resin-based film-forming agents with higher molecular weight and narrower distribution, the film-forming brittleness is high, hydrophobic-sweat-poor, air permeability is low, and the film-forming time is fast. And in the case of decreasing molecular weight and almost constant or broadened polymer dispersibility index, i.e., wider distribution, MQ silicone resin showed softer, better oleophobicity, average hydrophobicity and sweat resistance, longer film formation time, and higher permeability.

(1) The properties of MQ silicone resin are somewhat related to its molecular weight, size, and distribution state, i.e., when its molecular weight is larger, it exhibits brittle film formation, shorter film formation time, and lower air permeability. When the molecular weight is small, the MQ resin has low film brittleness, long film formation tim,e and high air permeability.

(2) When the molecular weight is in the range of 4,000~8,000 Da, the hydrophobicity and oleophobicity of MQ resin are both enhanced with the increase of molecular weight; when the molecular weight is around 8,000 Da, the hydrophobicity of MQ resin is low, and then enhances with the increase of molecular weight, while the oleophobicity decreases with the increase of molecular weight.

3. What are the film-forming agents?

3.1 Classification by solubility

Oil-soluble film-forming agent: can be dissolved in grease solvent, used in oily systems or formulations that need good compatibility with grease. Water-dispersible film-forming agent: can be dispersed in water, suitable for water-based or oil-in-water (O/W) type of sunscreen formulation system, is the most commonly used type.

3.2 Classification by chemical structure

(1) Vinyl pyrrolidone derivatives: good film-forming properties and skin affinity, good flexibility of the film after film formation.

(2) Acrylic acid polymers: fast film formation, film hardness, and wear resistance, and can be adjusted through the polymer structure to change the film performance.

(3) Organosiloxanes: excellent water resistance, breathability, and smooth touch, after the film, can give the skin a good sense of dryness and softness.

(4) Polyurethane: tough film, friction resistance, good adhesion to the skin, but also adjusts the flexibility and hardness of the film. (5) Polyester: stable film-forming properties, good compatibility with other components, can form a uniform and continuous film on the skin surface.

Different film-forming agents in the enhancement of oil-in-water sunscreen system performance show significant.

4. How to choose the film-formers?

Current long-lasting color cosmetics technology is mostly based on continuous covering “film-forming agents”, but there is a lack of universal formulation guidelines. The “soft” + “hard” formulation strategy focuses on the interactions between non-volatile components to understand that “soft” and “hard” inherent material properties of non-volatile blends can help predict and optimize the long-lasting performance of continuous layer.

If sebum is miscible with nonvolatile ingredients, it will reduce the “hard” “soft” ratio and weaken the binding of pigment to the skin; choosing ingredients with low miscibility with sebum will reduce the negative impact of sebum. Tips: When we choose the soft matching of film-forming agents, we can choose ingredients that are compatible with film-forming agents and less compatible with sebum, which can bring more durable makeup.

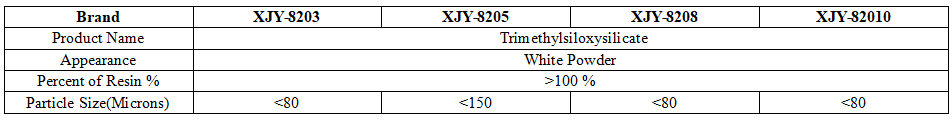

XJY-8203 Trimethylsiloxysilicate TMS

XJY-TMS mainly contains mono-functional Si-O unit (M unit) and tetra-functional Si-O unit (Q unit), structurally organic groups are attached to silicon atoms, and the whole shows a dense three-dimensional spherical structure. It is suitable for film-forming agents in various states, and can be used with super soft and hard films. XJY TMS powder can also be mixed with another organic solvent. The same amount of silicone TMS powder can have better film-forming ability than other components.

The film-forming agent with dry skin feel and hard texture holds makeup better than the film-forming agent with sticky skin feel and soft texture; the oil-soluble film-forming agent holds makeup better than the water-soluble film-forming agent; the film-forming agent holds makeup better than the oil with film-forming effect; the foundation formulated with low-viscosity silicone oil holds makeup better than the foundation formulated with high-viscosity silicone oil, and low-viscosity silicone oil is more suitable for the development of makeup-holding foundation.

5. Why choose silicone film-forming agent?

5.1 Excellent film-forming properties

Silicone film-forming agents can form a uniform, transparent, and strong film on the skin surface, which not only has good flexibility and ductility but also provides long-lasting protection.

This film is breathable, with a molecular spacing of 0.2-0.3nm, allowing a water vapor passage rate of ≥500g/(m²-24h), which can avoid problems such as smothering acne due to prolonged skin coverage.

5.2 Waterproof, anti-sweat, and durable

The film formed by the silicone film-forming agent has excellent waterproof and sweat-resistant properties, which can effectively prevent the loss of cosmetics after sweating or contact with water, ensuring that the makeup lasts.

In sunscreen products, it can assist in increasing the SPF value, reducing the amount of physical sunscreen added, while ensuring that the effect of sun protection in a variety of environments can remain stable.

5.3. Improve skin feel

Silicone film-forming agents have good lubricity and smoothness; their uniform distribution can significantly improve the smooth feel of cosmetics, making them softer and silkier, and enhancing the consumer experience.

It can also reduce the greasiness of the product, making the skin feel fresh.

5.4. Multifunctionality

In makeup products, silicone film-forming agents can help disperse color powder, improve the gloss and durability of the product, while achieving rapid drying and styling.

In skin care products, it can lock the water, prevent water loss, and have a moisturizing effect, especially for dry skin.

5.5. High safety

Silicone film-forming agent has a very low sensitization rate, tested by OECD 406, the sensitization rate is <0.03%, much lower than traditional ingredients such as lanolin (and is purer than natural appearance). It has safe chemical properties.

It also has good thermal and chemical stability, with a temperature range of -50℃ to 250℃.

5.6. Formulation flexibility

Silicone film-forming agent can be well compatible with a variety of other components (such as mineral oil, vegetable fats and oils), with a compatibility index > 0.95.

It can also be combined with other polymer materials through chemical modification to further optimize performance, such as with acrylic film-forming agents to enhance water resistance and oil resistance.

6. How to make silicone film-forming agents?

The silicone cosmetic film-forming agent market has shown steady growth in recent years. In the field of cosmetics, it has a wide range of applications, covering a variety of categories such as sunscreen, color cosmetic products, and personal care, and hair care products. Silicone film forming agent can also used in drug substance to keep water binding properties in yield tablets in drug delivery(wet granulation). How can we improve the competitiveness of our products?

XJY Silicone is one of the leading silicone MQ resin and VMQ silicone manufacturers in China. With more than 30 years of R&D and manufacturing experience in the silicone industry, more than 15 related patents and technical support, our silicone raw material products can meet the needs of the cosmetic field and support the provision of diversified customized solutions.

![]()