With the increasing refinement of color cosmetics and the demands of consumers, not only are color cosmetics required to have better efficacy, but they are also expected to provide good skin feel and have a pleasant appearance. Among them, silicone gel is being added more and more to makeup to increase the smooth skin feel, so what does silicone elastomer gel normally refer to?

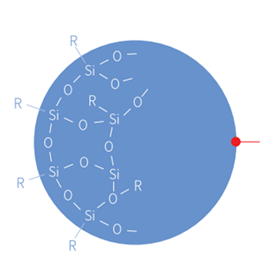

Silicone gel is an adhesive composed of silicone-oxygen chain links, which are formed when the side chains and other organic groups through the silicon atom are connected, and can be regarded as discrete cross-linked siloxane elastomer gel particles dispersed within a carrier fluid. Therefore, this is complex with components of inorganic structure and organic groups.

Let's talk more about it:

- Why use silicone elastomer gel?

- What is the chemical principle of silicone elastomer gel?

- What is the role of silicone elastomers in cosmetics?

- What determines the skin feel of a silicone gel?

- How to choose the solvent for silicone gel?

- What are the applications of silicone gel in color cosmetics?

- How to choose silicone elastomer gel?

1. What are the advantages of silicones for cosmetics?

In general, there are three different types of silicones: (1) silicone oils, (2) elastomers (3) resins.

Silicone polymers are a very diverse group of compounds that can be used in a variety of different types of formulations. The unique aesthetics they provide are the reason for their popularity in the formulation of color cosmetics and personal care products. Choosing the right polymer can provide formulations with.

(1) Lower surface tension

(2) Unique skin feel

(3) Film formation

(4) Reduced pigment migration

(5) Foaming of hydroalcoholic solutions;

2. Why use silicone elastomer gel?

For a long time, makeup has given the impression of being heavy and greasy. Although increasing the amount of organic oil improves the anti-moisture of makeup, it reduces the comfort of use and leads to an unnatural look. Makeup products with silicone gels have successfully overcome these shortcomings, although they still appear as oil or wax films.

It can be used as an effective rheological thickener for low-relative-mass siloxane fluids, and its addition to skin care and color cosmetic products provides both a mild initial sensation of low-relative-mass siloxane fluids and a film-forming sensation while maintaining the high viscosity of skin care and color cosmetic products.

(1) Tunable performance

Silicone elastomer gels can change the degree of cross-linking, silicon-hydrogen group content, catalyst amount, and other parameters to modify the performance of silicone gel. The fluidity, hardness, curing time, and other properties of the product can be regulated according to application requirements.

(2) Surface Spontaneous Adhesion

This natural bonding allows the gel to physically adhere to the surface of most common materials without the need to add adhesive additives or spray coating binders on the bonding surface before curing.

(3) Stable physical and chemical properties

Not much affected by temperature, this can be used in a wide temperature range (-60 ℃ ~ 200 ℃).

(4) Repeatable use

They have the characteristics of repeatable operation, repairable, high flexibility, etc., with an extremely low shrinkage rate.

3. What is the difference between a silicone elastomer and a silicone resin?

Liquid silicones are linear compounds that are not cross-linked. As such, they are liquid, and even at high viscosities, because the product structure is not crosslinked, they remain liquid and can flow significantly. This type of very high viscosity polymer is commonly referred to as silicone. Elastomers are polymers with a crosslinked structure that restricts the polymer's ability to rotate freely and prevents it from forming a stronger network. Due to the limited concentration of cross-linking groups, elastomers tend to restore their shape. As the crosslink density continues to increase, a stronger system is formed, called a silicone resin. As the cross-linking increases, the ability of the polymer to rotate freely decreases significantly, resulting in a stronger web structure. Compression of silicone resins produces debris, but they are restored to their original state.

4. What are the properties of silicone elastomers?

(1) Initial skin feel - dry, powdery skin feel

(2) Soft cushioning action - length of spreading time

“soft cushioning”/action time "soft cushioning “ If the mixture is applied to the forearm, the ”cushion" effect is the amount of mixture remaining between the fingers and the forearm. Cushioning is considered to be a combination of viscosity and resistance to flow.

(3) Final polymer skinfeel - dry, waxy skinfeel, short duration of action

(4) Other properties - anti-migration/encapsulation of color powder

4. What is the chemical principle of silicone elastomer gel?

Silicone compounds react to form a polymer cross-linking network, the cross-linking network is filled with solvent molecules in the gaps, and the resulting dispersion system is called the silicone gel, which is due to the interactions between the cross-linking network and the solvent to reflect the unique dry, silky skin feel. Silicone gel can provide a good skin feel. The mechanism is similar to the process of sponge water absorption, the crosslinked network of the silicone elastomer gel is dissolved by the solvent, and the solvent molecules fill the gaps between the crosslinked network, so that the application can provide the skin with lightness and smoothness of the solvent after the solvent has been absorbed or volatilized, and there is a sense of film formation related to the structure of the crosslinked network itself.

5. What is the role of silicone elastomers in cosmetics?

Some commonly used oil phase moisturizers, such as glycerin, produce a greasy feeling when added in high amounts to skin care and color cosmetics products, resulting in products that are not easy to distribute and spread on the skin; while panthenol or niacinamide produce a sticky feeling when added in high amounts to skin care and color cosmetics products.

In order to improve the spreadability and crispness of skin care and color cosmetic products, it is generally necessary to add silicone fluids of low relative molecular mass to give cosmetic compositions a dry, smooth, uniform touch and to increase visual luster. However, while the low relative molecular mass siloxane fluid imparts the desired properties to the composition, its volatile and low viscosity properties make it difficult to retain in the formulation, easy to separate, and may even flow uncontrollably through the skin during use, limiting its application in the cosmetic composition. If solution viscosity is increased and evaporative loss of volatile low relative molecular mass silicone oils is slowed by the use of common thickeners, the spreadability of the silicone oils may be reduced as well as leaving a severe slippery feel on the skin.

The silicone gel for cosmetics can be regarded as an effective thickening agent for low relative molecular mass silicone fluids, providing unique dry, silky, and other skin sensations, and thus becoming a very promising raw material for daily chemicals with good market application prospects.

XJY-804-M, INCI product name: Dimethicone/Vinyl Dimethicone Crosspolymer/ Trimethylsiloxysilicate/ Cyclopentasiloxane, is a silicone rubber elastomer gel dispersed in the Cyclopentasiloxane liquid system. This silicone elastomer is a regular sphere with excellent anti-slip properties, which can be applied to a variety of formulations and has good compatibility with other materials. In addition, dimethicone vinyl has excellent film-forming properties and has good applications in color cosmetics.

6. What types of silicone elastomers are available?

Elastomers, especially those modified by the addition of organofunctional silicone polymers, are powerful tools for altering the aesthetic properties of most personal care products. This approach provides cosmetic formulations with unique and diverse skin aesthetics. These aesthetics provide perceptible differences to the consumer, with the difference in elastomer being the only difference in the formulation. This study also demonstrates that silicone elastomers containing blends of organofunctional groups are useful aesthetic modifiers for skin care products.

Polymer A Parent Polymer

INCI Name: Cyclopenta Dimethicone (and) Dimethicone/Vinyl Dimethicone Crosspolymer

When the polymer is applied to the skin, the polymer is first placed on the index finger and then applied to the forearms, where it initially has a distinctly powdery and dry skin feel. At the beginning, the skin is obviously powdery and dry, and as it continues to be applied, there is a “cushiony” touch, because the action time is short, the “cushiony” effect disappears. Finally, a dry skin feel is achieved.

Other polymers with less than 1% silicone additives in the parent polymers show the same compatibility.

Polymer B: Alkyl organosiloxane additive in parent polymer

INCI Name: Cyclopenta dimethicone (and) polydimethylsiloxane/vinyl dimethicone crosspolymer (and) polydecene (and) cetearyl stearate polydimethylsiloxane/vinyl dimethicone crosspolymer

When the polymers are applied to the skin, the polymers are first placed on the forefinger, and then the forearm. When the polymer is applied to the skin, it is first placed on the index finger and then on the forearm. A powdery, dry skin feel is apparent at first, and as the application continues, a “cushiony” feel is achieved, with a longer “cushiony” effect than with Polymer A. The final waxy skin feel is achieved. Finally, a waxy skin feel is achieved. The change in skin feel is due to the presence of alkylidene silicones in the composition.

Polymer C Spreading additive added to the parent polymer

INCI Name: Cyclopenta dimethicone (and) polydimethylsiloxane/vinyl dimethicone crosspolymer (and) perfluorononyl dimethicone

When the polymers are applied to the skin, the polymers are first placed on the index finger and then on the forearm, where the skin sensation of a distinctly powdery dry skin texture is initially apparent, and then continues to develop with a “cushiony” skin sensation. As the polymer is applied to the forearm, there is a distinctly powdery, dry skin feel at first, and as the application continues, there is a “cushiony” feel, which lasts less time than Polymer A, with the “cushiony” feeling being shorter in duration. The final result is a smooth skin feel. The change in skin feel is due to the presence of alkylidene silicones in the composition.

Polymer D: Addition of MQ Resin to the Master Polymer

INCI Name: Cyclopentadimethylsiloxane (and) Dimethicone/Vinyl Dimethicone Crosspolymer (and) Trimethylsilanesiloxysilicate

When the polymers are applied to the skin, the polymers are first placed on the index finger and then on the forearms, where a powdery and dry skin feel is evident initially, and then, as the polymer is continued, a “cushiony” skin feel develops. A “cushiony” feel is initially apparent with a distinctly powdery, dry skin feel and continues with a “cushiony” feel, which is shorter in duration than polymer A. The final smooth skin feel is achieved. Finally, a smooth skin feel is achieved. The change in skin feel is due to the presence of alkylated silicones in the composition.

XJY-804-M, INCI Product Name: Dimethicone/Vinyl Dimethicone Crosspolymer/Trimethylsiloxysilicate/Cyclopentasiloxane is a silicone rubber elastomer gel dispersed in a cyclopentasiloxane liquid system.

7. What determines the skin feel of a silicone gel?

The skin feel of a silicone gel is determined by the interaction of the crosslinking network and the solvent. By combining different crosslinking systems and different solvents, it is possible to prepare silicone gels that provide a variety of skin feels, such as dry, silky, powdery texture, and moisturized, for skincare and cosmetic products.

The crosslinking system of common cosmetic silicone gels is generally formed by the silica-hydrogen addition of high relative molecular mass polysiloxanes containing Si-H bonds and compounds containing unsaturated hydrocarbon groups, such as dienes and diynes, under the action of a hydrogenated silanization catalyst. The formation of a three-dimensional crosslinked network by the silica-hydrogen addition reaction is characterized by the absence of by-products and the ability to accurately define the crosslinking points and the resulting network structure. The interaction between the crosslinked network and the solvent used determines the properties and skin feel of the silicone gel, but the structure of the crosslinked network has a greater influence.

8. How to choose the solvent for silicone gel?

The choice of solvent for silicone gels generally depends on the characteristics of the crosslinked network and the requirements for skin feel, but it is basically a matter of choosing between low relative molecular mass straight chain or cyclic siloxanes, organic solvents, and mixtures of low relative molecular mass straight chain or cyclic siloxanes and organic solvents.

The use of cyclic siloxanes as solvents in silicone gels provides a mild initial sensation and maintains the high viscosity of the product, but cyclic siloxanes are inherently low viscous and mobile, are not readily retained in the formulation, and have limitations in terms of performance or compatibility distribution. Linear silicone fluids, when used as solvents, can provide a different performance or compatibility distribution, but often require higher levels of silicone polymer crosslinking networks to obtain the desired viscosity through cyclic silicone, which not only increases cost but also tends to produce a negative "clumping" sensation on the skin.

9. What are the applications of silicone gel in personal care?

Silicone gel due to its unique sensory properties, reduces the viscosity of the formulation and increases the visual luster and powdery texture of the product, widely used in skin care products, hair care products, and makeup, especially in the color cosmetics in the application of trend is increasing year by year. Among the category segmentation:

The most used silicone gels in the color cosmetics market are liquid foundation, followed by lip glosses, pre-makeups, powders, eye shadows, multi-purpose makeups, concealers, blushes, eyebrow pencils, eyeliners, eye shadow, and so on.

In the skincare market, silicone gel is mainly used in face care products and neck care products, followed by sunscreen, eye care, body care, kits, hand/nail care, lip care, foot care, hair care, and others.

(1) Sun care

Excellent adhesion and skin-friendliness, effectively blocking UV radiation, AND increasing SPF and PA ratings.

(2) Liquid foundation

Excellent smoothness and spreadability, excellent makeup retention

(3) Anti-wrinkle cream

Excellent film formation and skin feel, long-lasting effectiveness

(4) Deodorant or antiperspirant

Appropriate silicone gels provide a smooth skin feel and reduce the likelihood of dehydration and shrinkage of the product.

(5) Cosmetics - lipsticks, lip glosses, BB creams, concealer sticks, etc.

Silicone gels containing MQ silicone resin and containing C18 or stearoyl side chain not only enable the formation of a high-strength continuous film with good adhesion after evaporation of the carrier solvent, improve the spreading performance of pigments and other particulate-type actives, and effectively reduce the agglomeration phenomenon of inorganic sun care in sun care products, but also have better anti-migration properties, which is conducive to its application in color cosmetic formulations.

![]()

10. How to choose silicone elastomer gel?

It is a unique cosmetic raw material that can provide a velvety soft cushion feeling and good spreadability, but also can play a role in moisturizing and hydrating, soft focus on the role of covering, both pliable, film-forming, and providing water resistance, widely used in skin care products, color cosmetics products. How to make your products more popular in the market?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone elastomer powders and elastomer gels can provide customized solutions according to your application needs (personal care products and color cosmetics).