Vinyl silicone resin has a good development prospect. In recent years, the production capacity of vinyl silicone resins has been expanding with technological advances, and the rapid development of downstream industries such as electronics and construction has also led to increasing market demand. In addition, environmental protection and sustainability have become the focus of the industry, and more high-performance, low-VOC, and biodegradable products will be developed in the future. How is vinyl silicone resin used in dentistry?

Vinyl silicone is a high-performance material that offers a number of significant advantages. First, it is highly resistant to heat and can remain stable in extreme environments, making it suitable for high-temperature scenarios( such as humidity and moisture, sunlight), such as aerospace. Secondly, it is chemically resistant to acids, alkalis, and solvents, effectively protecting electronics from external chemicals. In addition, it has good mechanical properties, which can significantly enhance the mechanical properties of silicone rubber, such as hardness and tensile strength.

There are 8 aspects to introducing silicone vinyl for the density field:

- What is vinyl silicone?

- Why use silicone rubber in dentistry?

- What is the synthesis method of vinyl silicone?

- What are the properties of vinyl silicone rubber?

- What is the industrialized preparation of vinyl silicone rubber?

- What is the application of vinyl silicone resin within dentistry?

- What is the future of vinyl silicone resin?

- How to make vinyl silicone better?

1. What is vinyl silicone?

There is a wide variety of functional silanes, including methacryloyloxy silanes, amino silanes, sulfur-containing silanes, vinyl silanes, epoxy silanes, and other silicone products. Vinyl silane, also known as vinyl siloxane, is an organic compound. Vinyl silane is a colorless, transparent liquid with an irritating odor, soluble in organic solvents containing benzene, ether, and alcohol, insoluble in water. Vinyl silane has a wide range of uses, including textiles, medicine, building materials, the chemical industry, and other fields as its main demand end.

The core structure(base polymers) of vinylsilane materials is that silicon atoms are connected with vinyl through a Si-C bond and oxygen. The double bond of the vinyl group gives the material its reactivity, while the siloxane skeleton provides thermal stability and hydrophobicity. In polymers (e.g., vinyl silicone rubber), the vinyl group acts as a cross-linking point to form a three-dimensional network structure by free radical reaction or platinum-catalyzed hydrogenation addition.

2. Why use silicone rubber in dentistry?

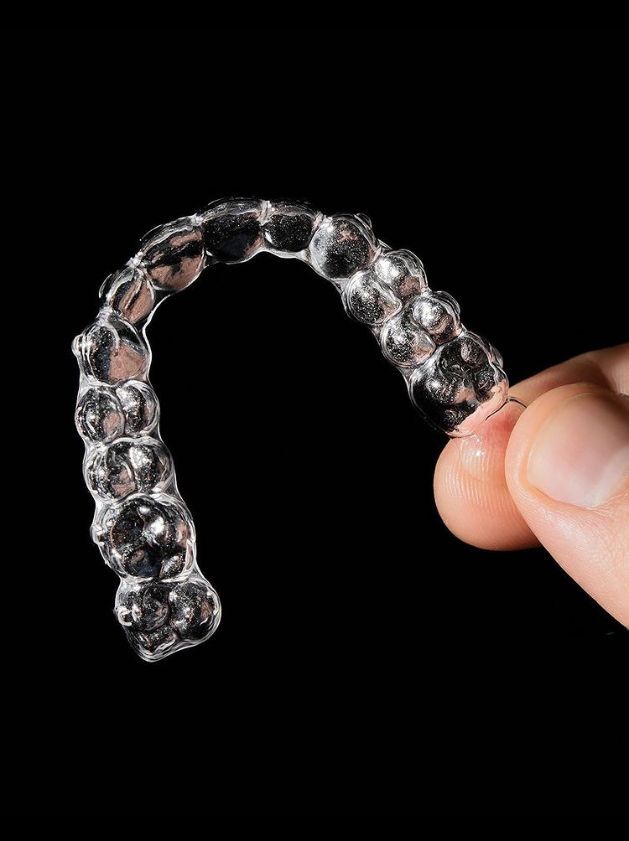

Silicone rubber impression materials have become one of the more desirable impression materials used in clinical practice due to their high strength, elasticity, accuracy, dimensional stability, and plasticity. Although it is widely used in the field of dentistry, but there are still some performance deficiencies: such as poor surface wettability, presenting a certain degree of hydrophobicity, affecting the impression material on the details of the hard and soft tissues of the oral cavity reproducibility; in addition, the existing silicone rubber material itself is not antibacterial this shortcoming will make the impression dry surface carries a large number of pathogenic microorganisms, cleaning is not good, becoming a source of cross-infection, so how to improve the hydrophilicity of the silicone rubber material and give it antibacterial properties is the current research hot spot, can improve proceeds.

3. What is the synthesis method of vinyl silicone?

(1) Direct synthesis:

Silane and vinyl halide coupling reaction (such as the Grignard reaction) in the copper catalyst to generate vinyl silane monomer.

(2) Hydrolysis and polycondensation:

Vinyl silane monomer is hydrolyzed under acidic conditions to produce silanol and then polycondensed into polysiloxane. The molecular weight and degree of branching can be adjusted by controlling the reaction conditions.

(3) Functionalization modification:

Introduction of vinyl in the polysiloxane chain through silicone hydrogen addition reaction, such as the use of hydrogen-containing silicone oil and vinyl cyclic reaction.

4. What are the properties of vinyl silicone rubber?

Decomposition temperature of up to 300 ° C or more (such as vinyl silicone rubber at 250 ° C still maintains elasticity).

(2) Mechanical properties:

Tensile strength 5-10 MPa, elongation at break 300-800%.

(3) Electrical insulation:

Volume resistivity > 10¹⁵ Ω-cm, dielectric constant 2.5-3.5 (1 MHz).

5. What is the industrialized preparation of vinyl silicone rubber?

(1) Raw material and process optimization

The production of vinyl silicone rubber requires high-purity vinyl cyclomers (e.g., D4Vi) and tetramethyldivinyl disiloxane. The use of a continuous fluidized bed reactor improves polycondensation efficiency and reduces the amount of platinum catalyst to less than 10 ppm, reducing costs.

(2) Crosslinking Technology Breakthrough

Peroxide Vulcanization: Dibutyl peroxide initiates free radical crosslinking for thick products.

Addition vulcanization: platinum-catalyzed silica-hydrogen addition, weed out by-products, suitable for precision electronic component encapsulation.

UV curing: new photoinitiators to shorten the curing time to seconds and reduce energy consumption by 70%.

(3) Green Manufacturing Trends

Bio-based silane feedstocks (e.g., SiO₂ from rice husks) and closed-loop recycling processes (e.g., supercritical CO₂ depolymerization) have become R&D priorities and FDA.

6. What is the application of vinyl silicone resin within dentistry?

XJY-9860/XJY-9866

Methyl Vinyl MQ Silicone Resin and Vinyl Silicone Fluid Solution

These additives are specifically designed to enhance the mechanical properties of addition-cured silicone elastomers.

XJY vinyl products consist of vinyl-functional silicone polymers and vinyl-functional MQ resins. This product combination is particularly suitable for the formulation of filler-free, transparent systems with high mechanical property requirements. In addition, it can significantly improve the mechanical properties of formulated systems containing fillers.

The introduction of vinyl functional groups can significantly increase the crosslink density of elastomers. In silicone elastomers, vinyl reacts with silicone hydrogen groups in an addition reaction to form a highly crosslinked network structure, which enhances the mechanical properties of the elastomer. This crosslinked structure enhances properties such as tensile strength, tear strength, and viscosities of the material.

● Good tensile strength, tear resistance

● High temperature resistance

● High transparency

● UV resistance, weather resistance

1. Highly transparent and hard VMQ silicone rubber,

2. Reinforcement filler for adding molded silicone rubber,

3. VMQ silicone rubber curing agent,

4. Low-hardness VMQ silicone elastomers,

5. Silicone gel

7. What is the future of vinyl silicone resin?

(1) Nanocomposite reinforcement: graphene/carbon tube doping increases tear strength by 3 times (Zhejiang University 2023 results).

(2) Smart response materials: pH-sensitive vinyl silicone for targeted drug release in the tumor microenvironment.

(3) Reversible crosslinked network: self-repairing material based on Diels-Alder reaction with 92% repair efficiency.

8. How to make vinyl silicone better?

Vinyl silicone resin also has high transparency and excellent optical properties with a high refractive index for optical applications. It has low volatility during the curing process, is not easy to produce bubbles, and apply excellent processing performance. In conclusion, vinyl silicone resin is soluble in a variety of solvents, easy to process and mix, a wide range of applications, which generally can be used for electronic potting adhesives, construction sealants, coatings, silicone pressure sensitive adhesive with good peel ability, and so on. Some products also have the advantage of environmental protection and non-toxicity, long shelf life, in line with modern environmental requirements. How to improve the competitiveness and fun of products? For more recommended care instructions and storing fun, please click our website address.

XJY Silicone is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, more than 15 related patents and technical support, silicone raw material products to meet the needs of the dental field to support the provision of diversified customized solutions and effctive speed.