Nowadays, the popularity of electronic devices has greatly facilitated our daily life, and the protection of electronic device screens has also become our daily life. Most of the electronic equipment process is a more delicate, multi-step process, high complexity of the parts gave birth to a lot of supporting industries, and pressure-sensitive adhesive materials in different areas play a pivotal role. Why are silicone pressure-sensitive adhesive solutions so popular?

Silicone pressure-sensitive adhesive series products, because of their good wettability, weather resistance ( in a wide temperature range), yellowing resistance, and non-residual adhesive properties, are ideal for the production of various types of electronic applications screen protectors, widely used in cell phones, tablet PCs, and other applications.

There are five aspects to introducing silicone psa:

- What is silicone psa?

- What are the advantages of silicone pressure-sensitive adhesive?

- How to use silicone PSA in the field of electronics?

- What are the specific applications of silicone psa?

- How to make silicone psa?

1. What is silicone PSA?

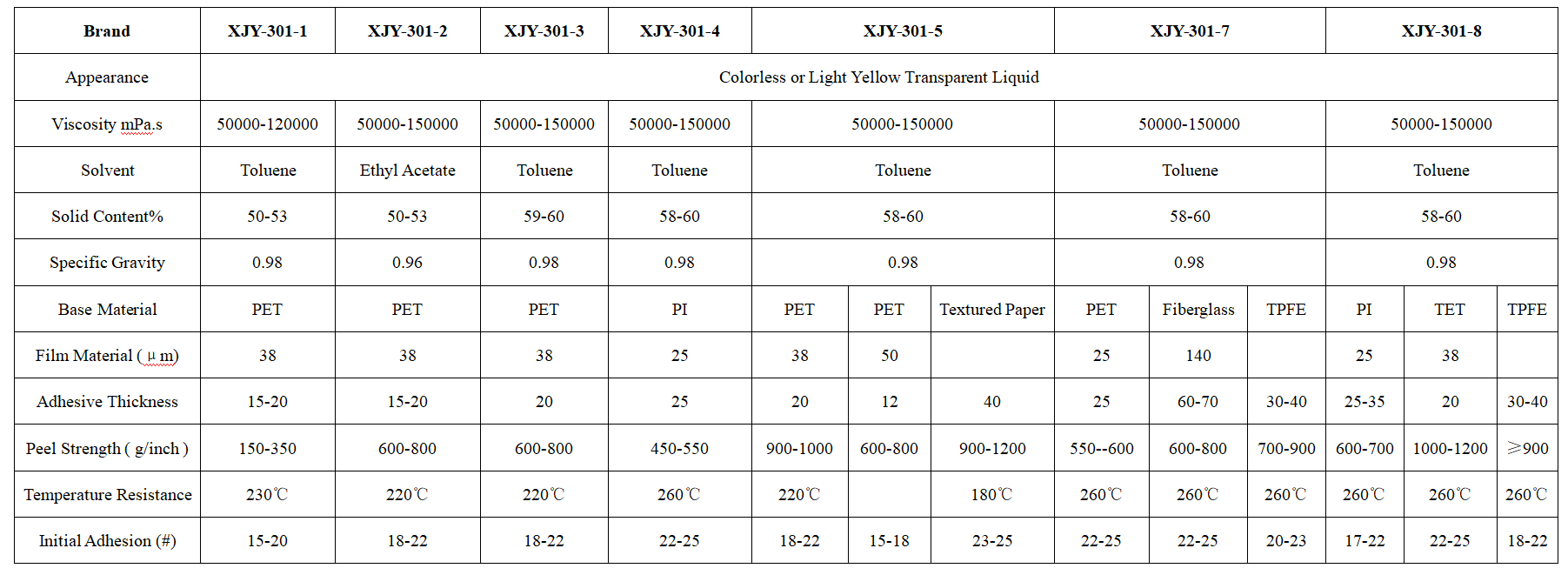

Silicone PSA generally refers to the silicone polymer as the main body of the pressure-sensitive adhesive, compared with the traditional acrylate pressure-sensitive adhesive, rubber-type pressure-sensitive adhesive. Silicone pressure-sensitive adhesive has good resistance to temperature, water, UV, aging, exhaust, etc., and is more suitable for outdoor environments. XJY silicone pressure sensitive adhesive has XJY-301, XJY-302 series products, which are platinum plus molding silicone pressure sensitive adhesive, heat curing, many substrates without primer treatment, peeling force can be done to achieve the requirements of the range of 0 ~ 1200g ( medium and comfortable) and have no residue or can remove with oil.

XJY-301 Silicone pressure-sensitive adhesives

It is made from the specific structure of silicone resin and high molecular weight polydimethylsiloxane in cooperation with organic adhesive, which is suitable for specific scene conditions.

Compared with natural rubber, it is characterized by heat resistance, high stability, good electric insulation, good transparency, high peel adhesion, chemical resistance, etc. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care, and mica tapes, splicing tapes, protective films other fields.

2. What are the advantages of silicone psa?

(1) Stable bonding force:

Silicone adhesive usually use high peel (1000g/in) and low peel silicone (1g/in) mixed, especially in the formulation of more than 100g/in, the high tack dosage of the subtle differences in the finished product peel force has a big impact on the stability of the poor, so the silicone pressure-sensitive adhesive, with a stable peel force, anchoring and aging performance is excellent, to solve the peel force is not controllable problem. XJY Silicone developed silicone pressure sensitive adhesive with silicone resin, 107 glue, and toluene solution with different ratios, which can realize different peel force levels intervals, to meet the customer's in a variety of occasions in the application of the requirements of use with convenience and flexibility.

(2) Good coating leveling appearance:

solvent-containing silicone itself contains toluene, coating method selection of micro-concave, anilox roller coating, comma squeegee, etc., all need a solvent to dilute to reduce the viscosity of the coating, good leveling appearance and the choice of solvent is related to the general use of mixed solvents (toluene/ethyl ester/butanone/gasoline/isopropyl alcohol, etc.).

(3) Good anchorage:

Silicone pressure-sensitive adhesives usually do not need primer treatment, in addition to special substrates and requirements. anchorage depends on the molecular structure of silicone products and the corresponding anchoring agent to cope with the downstream application of different materials and environments, to meet user requirements. Anchoring agent additive is not the more the better, adding too much will bring negative effects.

(4) Excellent air venting:

When laminating the tempered film of a cell phone, users would like the whole protective film to be able to expel air bubbles and finish the lamination quickly with a gentle press, which puts forward higher requirements for the air venting of the pressure-sensitive adhesive. New Jiayi silicone low-viscosity pressure-sensitive adhesive can realize the technical requirements of low viscosity and fast exhaust.

(5) High temperature and high humidity aging:

the complexity of the supporting industry chain of electronic products, facing harsh environments during transportation, such as hot summer/export containers, etc., which puts forward the requirements for the aging resistance of the pressure sensitive adhesive used, and the new Jiayi pressure sensitive adhesive series products have excellent high-temperature and high humidity aging resistance, with no adhesive peeling and no residual adhesive.

(6) Longer bath life:

Bath life is closely related to the structural composition of the silicone pressure-sensitive adhesive product itself, in addition to the formula and dosage order, temperature and humidity, solvent purity, adhesive flow state, impurity contamination, and so on.

(7) Low-temperature curing:

Normal recommendations for silicone pressure-sensitive adhesive curing, film surface temperature control at 150 degrees above, but for some thin substrates or temperature resistance is not enough, the formulation needs to be adjusted to achieve low-temperature curing, such as 100-130 degrees. Not recommended below 100 degrees curing, there will be poor curing, silicon transfer, large and unstable peeling force phenomenon.

(8) Less silicon transfer:

Silicone pressure-sensitive adhesive, silicon transfer, or residual glue will directly affect the surface properties of the protected object; the amount of silicon transfer depends on the molecular structure of the adhesive, the degree of online curing, and formulation design.

3. How to use silicone PSA in the field of electronics?

Pressure-sensitive adhesive is a kind of adhesive material that produces viscous flow through the action of slow and appropriate external force, realizes the close contact with the surface of the affixed object, produces intermolecular force, and realizes interfacial bonding, It also has high peel adhesion.

(1) In the field of wireless charging, pressure-sensitive adhesive tape helps to bond, fix, and protect the modules at the receiving end and the transmitting end for energy efficiency.

(2) In the field of display, optical pressure-sensitive adhesive is used in the screen for all kinds of optical materials bonding, so that in high temperature and high humidity conditions still maintains optical transparency, to ensure the clarity of imaging.

(3) On a variety of “delicate” electronic parts (such as the screen and its components) in the process of making and shipping process for protection, to prevent its transportation, the process may be caused by scratching and bumping, and damage.

Silicone pressure-sensitive adhesive is widely used in the preparation of a variety of electronic industry protective films for the transportation of precision parts, manufacturing, and use to provide a full range of protection.

4. What are the specific applications of silicone psa?

4.1 Glass process protection

Product features: adsorption, exhaust, dust, high cleanliness, no residual adhesive, high temperature resistance, anti-friction, and easy to tear.

Application scope: assembly line assembly, transportation, surface protection film.

4.2 Graphite protective film

Application features: strong adsorption, high stability, small tolerance, and no warping.

Application scope: disassembly, lamination, assembly, surface protection.

4.3 Foam protective film

Application features: strong adsorption, soft gel, stable aging.

Application scope: disassembly, lamination, support, positioning, assembly.

5. How to make silicone psa?

With the great development and application of artificial intelligence, big data, cloud computing, Internet of Things and other new generation of information technology, automotive electronic products come out in different layers, while the applied market requirements for auxiliary materials continue to work, in this context, the silicone light pressure-sensitive adhesive industrial market is expanding. Silicone PSA can also be used in personal care and the food industry because it can be used on skin. How to find the competitiveness of products formulated? Any error, please contact us.

XJY Silicone is one of the leading silicone MQ resin and VMQ silicone manufacturers set up in China, with more than 30 years of R & D and manufacturing experience in the silicone industry, with more than 15 related patents and technical support, silicone raw material products to meet the needs of the field of pressure-sensitive adhesives (also in silicone rubber field) to choose the provision of diversified customized results!

![]()