In recent years, with the continuous improvement of requirements for equipment safety and efficient operation in industries such as energy, chemicals, power, and metallurgy, the protection and functional upgrading of industrial pipeline systems have increasingly attracted attention. High-temperature pipelines, which are subjected to prolonged exposure to heat, chemical corrosion, moisture, and external impacts during operation, often face issues such as paint layer aging, peeling, cracking, and failure. These problems not only increase maintenance costs but also affect overall production safety and efficiency. The benefits of using silicone coatings for industrial pipeline protection include enhanced durability, superior resistance to harsh environments, and reduced maintenance needs.

As a highly integrated material combining organic and inorganic polymers, organosilicon methylphenyl silicone resin is designed for high-performance pipeline protection and often used as a core layer in high-performance silicone coatings. It stands out for its exceptionally high temperature resistance, excellent chemical inertness, superior adhesion, and weather resistance, making it the core raw material for the next generation of high-performance pipeline heat-resistant protective coatings. Such coatings are widely utilized not just for pipelines but for metal roofs, tanks, and automotive devices, providing enhanced protection against UV rays, ponding water, and other harsh elements.

There are six aspects to introducing silicone resin coating:

- What is silicone methylphenyl silicone resin?

- What are the requirements for pipeline heat-resistant coatings?

- What are the advantages of silicone resin coatings?

- What are appthe lications of heat-resistant coatings?

- What is are market prospect of silicone coating?

- How to enhance the performance of silicone coatings?

1. What is silicone methylphenyl silicone resin?

Silicone resins are a class of high-molecular-weight materials with a main chain of siloxane (Si-O-Si), where silicon atoms are bonded to organic groups (such as methyl or phenyl). Silicones are versatile polymers widely used in coatings, medical devices, and other applications due to their water resistance, thermal stability, and biocompatibility. Among these, methylphenyl silicone resins enhance thermal stability and improve resin toughness and adhesion through organic substitution of methyl and phenyl groups. Such resins form the key substrate for advanced silicone coatings.

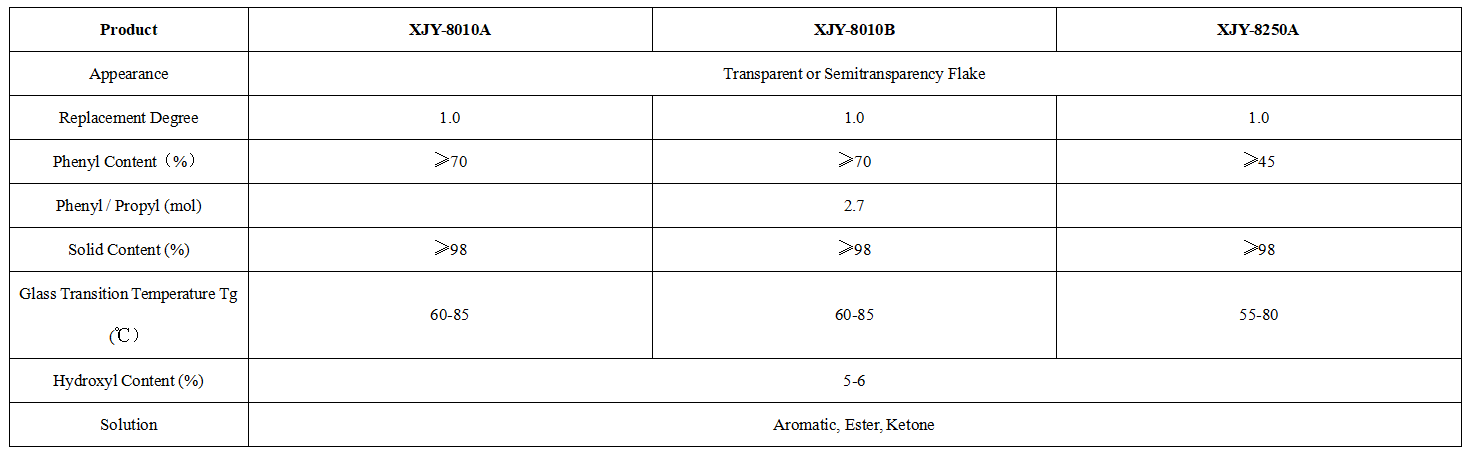

XJY-8010A/B/8250A Methyl Phenyl Silicone Resin

Methyl phenyl silicone resin can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat resistance, which hardly decomposes at 200℃ or even higher temperatures, and can be used to prepare all kinds of heat-resistant coatings, with heat-resistant insulation grade up to H class. Silicone resins have excellent weathering and UV resistance and can be used for powder and liquid coatings. Silicone resins have excellent weather resistance and provide all-around protection for equipment. Silicone resins have excellent weatherability and good adhesion. Silicone thin layers also have excellent weather resistance, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties.

The ratio of phenyl to methyl groups in methylphenyl silicone resin can be adjusted to suit different applications requiring thermal shock resistance and chemical stability. Methylphenyl silicone resins are often mixed with other additives to tailor their properties for specific uses. Its notable properties include:

A recent review of research highlights advances in the development and application of methylphenyl silicone resins in coatings and related technologies.

(1) Long-term heat and high temperature resistance:

Generally capable of withstanding operating temperatures ranging from 300°C to 600°C, with special formulations capable of withstanding even higher temperatures. This excellent resistance to heat makes such coatings suitable even for roof structures, metal chimneys, and building envelopes exposed to solar rays. After application, the coating may require several hours to fully cure and achieve optimal high-temperature resistance.

(2) Excellent weather resistance and corrosion resistance:

Provides highly durable protection against UV, oxidation, and chemical media such as acids and salts. The coating remains flexible and tough, absorbing impacts and preventing cracks.

In some cases, specific primers or surface preparations may be required to maximize corrosion resistance.

(3) Good adhesion and film-forming properties:

It can firmly adhere to the surfaces of metal, ceramic, concrete, fibers, and composite material pipes without complex substrate pretreatment, forming a seamless layer even around edges and seams.

Additionally, fabric reinforcements can be applied around penetrations to further strengthen the coating and help prevent leaks.

(4) Resistance to mechanical impact and thermal-cold cycling:

The coating does not crack or peel off, withstanding the “sudden temperature changes” typical of industrial environments.

2. What are the requirements for pipeline heat-resistant coatings?

(1) High-temperature stability

Industrial pipelines in sectors such as petrochemicals, power plant boilers, urban heating, and metallurgical equipment operate at temperatures ranging from 200°C to 600°C or higher. Traditional organic coatings (e.g., epoxy, polyurethane, acrylic) are often limited by temperature, tending to decompose, yellow, or fail above 150°C. A suitable silicone coating with excellent resistance to heat is a prerequisite for ensuring the long-term safe operation of pipelines. Proper curing of the silicone coating is essential to ensure it maintains its properties at elevated temperatures.

(2) Chemical Corrosion Resistance and Protective Capability

Various industrial media, such as acids, alkalis, salts, and high-temperature steam , can cause corrosion to pipelines, leading to premature failure or even safety incidents. Coatings with strong chemical resistance can significantly extend pipeline life and reduce maintenance and replacement frequency. Adding ceramic and nano additives and special pigments can further bolster resistance to elements and lengthen the warranty period.

(3) Excellent Weather Resistance and UV Aging Resistance

Outdoor pipelines are exposed to UV rays, wind, rain, and temperature fluctuations, requiring coatings with exceptional weather resistance and UV aging resistance. The presence of phenyl groups and special pigments within organic silicone coatings is crucial for counteracting damage from UV rays.

Advanced silicone coatings are also formulated to resist degradation from ultraviolet light, ensuring long-term durability.

(4) Excellent Adhesion and Safety/Environmental Performance

Pipeline surfaces may be made of carbon steel, stainless steel, aluminum alloy, ceramic, plastics, or other materials, requiring coatings with broad-spectrum adhesion. Additionally, silicone coatings are formulated to meet strict minimum regulations on VOCs, toxicity, and environmental impact.

3. What are the advantages of silicone resin coatings?

Silicone methylphenyl silicone coatings have become the “new standard” for pipeline heat protection due to their outstanding physical properties across multiple performance dimensions. A wide variety of silicone-based coating products are available to meet the needs of different industries, offering tailored solutions for applications in sectors such as roofing, electronics, marine, and medical devices.

(1) Exceptionally high temperature resistance and long-term protection

Methylphenyl silicone resin, thanks to its high-strength Si-O bonds and phenyl substitution, remains stable under high temperatures without decomposition or failure. This stability is also critical in silicone roof coating for metal roofs, where ponding water and UV rays stress traditional roof systems.

(2)Superior corrosion resistance and chemical resistance

The organic silicone backbone structure inherently possesses extremely high density and chemical inertness, effectively protecting against chlorides, sulfides, and nitrogen oxides. Its hydrophobic nature locks out moisture, reducing leaks and drainage issues, extending the life of the substrate.

(3) Durable Weather Resistance and UV Aging Resistance

Methylphenyl silicone coatings contain additives and pigments that provide robust UV and ozone protection, enabling an outdoor exposure lifespan of 15+ years with minimal weathering or aesthetic deterioration. This makes them increasingly utilized to restore and replace older coating systems.

(4) Excellent Adhesion and Flexibility

These coatings remain flexible to absorb expansion, contraction, and vibration, adapting to metal pipes and concrete structures, and forming seamless, strong adhesion even at seams, penetrations, and edges.

(5) Easy Application and Environmental Performance

Methylphenyl silicone resins and associated coatings can be sprayed, rolled, or brushed, and are compatible with a variety of methods, including heat-cured or ambient-curing approaches. They emit low VOCs, contain no harmful heavy elements, and fully comply with environmental standards.

For optimal adhesion, silicone coatings should be applied to clean, dry surfaces.

(6) Exceptional Reflectivity and Energy-Saving

Reflective silicone coatings (enhanced by special pigments and resins) can reflect UV and solar rays, reduce heat buildup, and help save money on energy costs by maintaining lower surface temperatures.

4. What are the applications of heat-resistant coatings?

(1) Power Plants and Thermal Pipelines

A protective coat is applied to metal supercritical steam pipelines, boiler flue ducts, and thermal networks, where silicone coating provides a robust layer of protection that can serve for decades even in harsh heat and weathering conditions.

(2) Petrochemical and Natural Gas Transmission Pipelines

In the petroleum, ethylene, and LNG sectors, silicone coatings demonstrate superior performance in corrosion and high temperature resistance, and are widely applied in critical projects worldwide.

(3) Urban Central Heating and Boiler Chimneys

Silicone roof coatings and pipe coating are often specified in city heating networks and boilers thanks to their cost-effectiveness, seamless installation, and long life cycle. Silicone roof coatings are also used for building envelopes and roof structures to provide durable, water-resistant protection and energy-saving benefits.

(4) Food, Pharmaceutical, and Fine Chemical Pipelines

The non-toxic, odorless, and flexible nature of silicone coating makes it ideal for high-purity gas and fluid lines where safety and hygiene standards are paramount.

(5) Marine Applications for Ships

Silicone coatings are widely used on ships to protect hulls and marine structures from biofouling and corrosion. These coatings help prevent marine growth, improve cruising performance, and extend the service life of ship components.

5. What is the market prospect of silicone coating?

(1) Global Market Size

According to Grand View Research and MarketsandMarkets, the silicone coating market for high-temperature applications is growing rapidly, projected to exceed USD 10 billion by 2028. This growth stems from the increased adoption across building, automotive, roof, and pipeline systems wishing to extend life and save on maintenance. One key advantage of silicone coatings is the ability to easily apply additional layers, allowing for simple renewal of protection and extension of warranties.

(2) China and Emerging Markets

Driven by policy and a strong building sector, China’s market for silicone-based coatings (including pipeline and roof applications) is surging, as systems demand longer warranty, increased life, and improved protection against moisture, heat, and chemicals.

(3) Technological Innovation and Supply Chain Upgrades

Advances in nano additives, eco-friendly resins, and intelligent monitoring (for seams, penetrations, and leaks) will empower a new era of “smart silicone coatings,” ensuring maximum performance and difference for global systems.

6. How to enhance the performance of silicone coatings?

Methylphenyl silicone coatings, with their excellent resistance to heat, weather, and corrosion, along with strong adhesion and environmental compatibility, are the ideal choice for restoring and protecting critical substrates across industrial pipelines, roofs, and building systems that face harsh outdoor elements. With ongoing innovation in additives, methods of spray and curing, and sustainability, their position in the market will only strengthen.

XJY Silicone is one of China's leading manufacturers of organosilicon MQ resins and VMQ organosilicones, with over 30 years of R&D and manufacturing experience in the organosilicon industry. Xinjiayi provides high-quality raw materials for silicone coating and silicone roof coating solutions, serving a wide array of industries and offering custom formulations to meet all your application requirements.

If you have a specific request or want to learn the difference that world-class silicone coating can make in your systems, contact Xinjiayi Silicone for expert technical assistance.

![]()