Silicone textile usually includes lubricant, fabric finishing agent, defoamer,and anti-adhesion agent for yarn and textile machinery. Silicone plays an important role in improving the quality and technology of textiles.

1. Silicone Textile: fabric finishing agent

Although synthetic fiber has many excellent advantages, it feels rough and hard, which affects the visual effects, tactile effects, and performance of the fabric. Therefore, it is necessary to finish the fiber and textile. Silicone fabric finishing agent has good comprehensive properties, which can not only meet the requirements of wear resistance, tear resistance, wrinkle resistance, straightness, and no ironing, but also soft, elastic,and super smooth, so it is widely used.

![]()

![]()

- Anti-wrinkle and iron-free finishing of silk fabrics and silk knitwear

The finished silk knitwear has softness, thickness, smoothness, high elasticity, and wrinkle resistance. Its application range includes anti shrinking and wrinkle-resistant finishing of silk, the soft finishing of silkworm silk, the soft finishing of triacetate/nylon imitation silk fabrics, non-ironing finishing of silk knitwear, etc.

- Super washability and relief finishing of woolen fabric

The outstanding advantage of silicone fabric finishing agent is that there is no chemical degradation in the process of finishing, at the same time, pilling is reduced, dry cleaning is resistant, and the finished clothes still keep the original softness of the fabric, achieving the effect of super washability or "relief". It can be used in shrink-proof finishing of the woolen sweater and finishing of thin wool blended textiles.

- Water-repellent finishing of the fabric

After various fabrics are treated with a silicone waterproofing agent, the following effects can be obtained: waterproof, bulky, soft, breathable, elastic, washable, anti-wrinkle, and can also increase the abrasion resistance, tear-resistance, and smooth handle of the fabric, improve its sewing performance. It can be used for water-repellent finishing of vinylon canopy canvas, polyester/cotton fabric, nylon silk, etc.

- Used as soft finishing of polyester chemical fiber fabric

After finishing, it can make the fabric feel soft, smooth, crisp, elastic, and full to a certain extent, which can greatly improve wrinkle resistance, tear-resistance, and air permeability. It can be used for soft finishing of pure polyester knitwear, yarn-dyed polyester/viscose medium, and long fabrics, etc.

2. Silicone Textile: coating on nonwovens and fabrics

Using silicone as a softener for non-woven fabrics is not only strong and soft but also easy to cut and sew. It can also reduce the surface tension of the resin binder, make the resin evenly spread on the surface of the fiber, and improve the utilization rate of the binder. Silicone fabric coating can improve the elongation and elongation recovery of knitwear, improve the abrasion resistance and shrinkage resistance of the fabric, has pressure rail resistance, and can produce an elastic hand-feel memory, which can promote the fabric to return to a certain balance position during wearing and after washing.

![]()

![]()

![]()

3. Silicone Textile: sanitary finishing of textiles

Sanitary finishing is also called anti-bacterial, anti-odor, anti-corrosion, and anti-mildew finishing. Silicone quaternary ammonium salt has the advantages of long-lasting antibacterial effect, safety and reliability, and wide antibacterial range. It can achieve the best antibacterial and antifungal properties by sanitary finishing and has excellent deodorant performance. It has excellent effects on antifungal and deodorization finishing for socks, sweaters, underwear, sportswear, carpets, household daily necessities, protection and decoration of ancient cultural relics, disinfection of medical surgical scalpels, etc.

4. Silicone Textile: defoaming during printing and dyeing

Silicone defoamer has the characteristics of low dosage and good effect. At the same time, it is harmless to biology, can reduce pollution, has no effect on other additives in the dyeing bath, and does not affect the colorfastness, Therefore, it has attracted more and more attention. Silicone defoamer can be used in four forms: silicone oil, silicone oil mixture, silicone oil solution, and emulsified silicone oil, which can be divided into non-aqueous phases defoaming and water phase defoaming in the application. It can be used for defoaming in dyeing, washing, bleaching, surface treatment, desizing, resin finishing, printing and dyeing, printing and dyeing solvent recovery, dry cleaning, jet dyeing, mercerizing, non-woven fabric and carpet production in the silk industry, bleaching and dyeing industry, and knitting industry.

![]()

5、Silicone Textile: lubricant and anti-sticking agent

Silicone compounds have extremely low surface tension, which can evenly wet the surface of synthetic fibers, or form a film on the surface, and have good thermal stability, less weight loss, and can reduce the generation of carbon powder and waste oxygen, thereby reducing air pollution. Besides, silicone can still maintain its lubricity when heated, which can reduce the parking time. Therefore, silicone has been widely used in the textile industry as a lubricant and anti-sticking agent for yarn surfaces and printing and dyeing machinery.

XJY Silicones

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

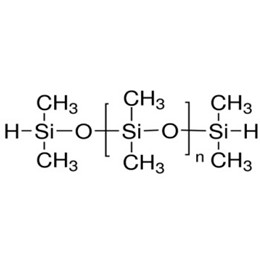

We manufacture and customize XJY-706 (1,1,3,3-Tetramethyldisiloxane (TMDSO)) and XJY-707 (Hydride Terminated Polydimethylsiloxane) can be applied to the Silicone Textile. Our manufacturing, R&D, and sales services obtained the ISO9001 certificate.

![]()