The role of the potting compound is to encapsulate the adhesive into the electronic product after curing the physical protection of the product, the potting compound is similar to the formation of amber, and can prevent electronic products due to wet weather caused by short-circuiting; in complex assemblies to provide stronger protection against chemical attack; in challenging environmental conditions to provide resistance to mechanical shock and vibration; and hidden high-tech circuits contain intellectual property rights and so on. The development of the modern industrial system has led to a variety of sealant materials, the current market is divided into three main categories of materials, epoxy resin potting compounds, polyurethane potting compounds, and silicone potting compounds. However, why began to choose to use silicone sealant on more than one occasion?

Epoxy resin potting adhesive is suitable for use at temperatures not exceeding 180 ℃, and is less flexible; polyurethane potting adhesive for electronic products urethane resin and polyurethane potting adhesive both mechanical strength and flexibility, a working temperature of 125 ℃. The nature of such products in the silicone resin and epoxy resin potting adhesive between is an economical alternative.

Silicone potting compound to organic polysiloxane as the base resin, with fillers, catalysts, and other functional additives composed of potting material, with excellent stability, water resistance, weather resistance, and UV resistance, and in the subsequent curing easy to mold, safe, and environmentally friendly non-polluting and other advantages. The silicone resin is also the most temperature-resistant potting adhesive in a product, with a working temperature of up to 200 ℃. These properties make silicone potting compounds in many fields has been widely used.

Let's talk more information about it:

- The definition of potting

- Silicone potting compounds

- How to make silicone potting compounds?

- What factors should be considered when using silicone potting compounds?

- What are the typical applications of silicone potting compounds?

- XJY silicone -the silicone potting compound raw materials preferred supplier

1. The definition of potting

1.1 What is potting

Potting is at room temperature or under heating conditions, through mechanical or artificial methods, the liquid compound is poured into the device with electronic component and circuit, and cured into a polymer insulating material with excellent performance.

1.2 How many kinds of potting

Potting is divided into two types: local potting and overall potting.

(1)Local potting refers to the potting of high-power devices, so that they are connected to the heat sink through thermally conductive potting silicone rubber material so that the heat generated is quickly transferred to the heat sink.

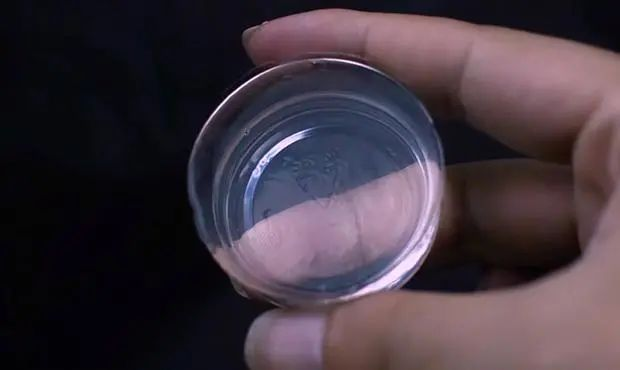

(2)Integral potting is the potting of all components inside an electronic product so that the heat generated is rapidly diffused and directly emitted to the external environment. When used, the two components are mixed and defoamed, then loaded into the required parts and vulcanized into a soft pliable rubber elastomer.

2. Silicone potting compounds

2.1 What is silicone potting compound

Silicone potting compound (also known as thermally conductive silicone potting compounds) refers to a class of electronic potting compounds made of soft pliable silicone rubber, including single-component silicone potting compounds and two-component silicone potting compounds.

The use of different components of the product scope and the use of the field has a great difference:

(1)The main advantage of the single-component potting compound is that it can be used directly, without defoaming, the operation is more convenient;

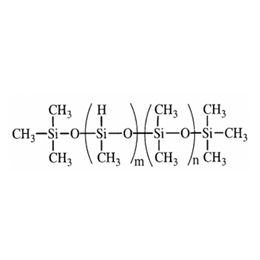

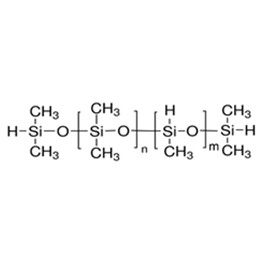

(2)Two-component silicone potting compound due to the need to mix the liquid base adhesive and catalyst or crosslinking agent, so it is generally used for insulating encapsulating materials or airtight shock-absorbing materials. (XJY-702 Low hydrogen silicone oil/711 Hydrogen terminated methylhydrogensiloxane dimethylsiloxane copolymer can be used as a crosslinking agent for a two-component organosilicon potting compound.)

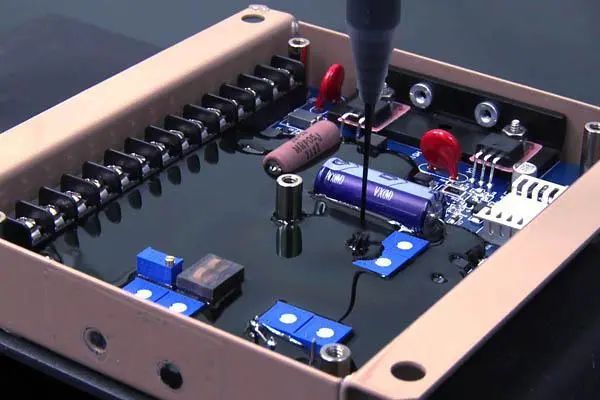

One of the common thermal conductivity potting adhesives is generally two-component. The two components are mixed and defoamed, then potted to the required parts and vulcanized into a soft pliable rubber elastomer. In addition to the function of heat dissipation and insulation, these products also have the function of shock absorption and three-proof. Currently widely used in LED power supply, light bulb built-in power supply, electric vehicle battery component and charging pile power module, as well as some electronic equipment bonding irrigation. Seals, play a role in heat dissipation, sealing and shock absorption.

2.2 What are the advantages of silicone potting compounds

Silicone material potting adhesive not only has more excellent modification ability and electrical insulation ability than epoxy resin, but resistance to hot and cold shock is also quite excellent, can withstand -60 ℃ ~ 200 ℃ of hot and cold shock, does not crack, and maintain elasticity, there is to improve the moisture-proof performance of the electronic component, because of the elastomer after curing, so potting in the electronic components, but also play a very good anti-impact ability, resistance to outdoor Outdoor UV and atmospheric aging performance is also very good.

(1)After potting, it is easy to clean up and dismantle, so that the electronic components can be repaired and the repaired parts can be re-injected with a new potting compound.

(2)Silicone can maintain the original physical and electrical properties in a variety of working environments, resistance to ozone and ultraviolet degradation, and playing a good stability performance.

(3)Silicone has stable insulating properties, can effectively prevent environmental pollution, is cured to form a soft pliable rubber elastomer, in a wide range of temperatures and humidity, and can effectively eliminate the effectiveness of the impact and vibration produced.

(4) Silicone can be effective protection of some electronic devices or sensitive circuits, in the device of electronic modules, its structure and shape is to play a protective role.

3. How to make silicone potting compound

3.1 What is the formula for the preparation of silicone potting compound

According to the different curing mechanisms, silicone potting compounds by the condensation and addition of two systems.

(1) Two-component condensation type

Generally in a vacuum kneading machine, a certain proportion of 107 silicone rubber, alumina, magnesium hydroxide and other functional fillers at a certain temperature for a certain period of time, and then a certain amount of viscosity of vinyl silicone oil, high-speed shear disperser stirring for a certain period of time to prepare component a. Crosslinking agent, catalysts and other residual components according to a certain amount of stirring to prepare the component B.

(2) Two-component molding

Two-component is a certain amount of vinyl silicone oil, platinum catalyst, and functional fillers in a vacuum kneading machine fully mixed into component a, vinyl silicone oil and hydrogen-containing silicone oil mixed with the functional fillers, inhibitors and viscosity enhancers uniformly mixed in a vacuum kneading machine to make component B. (XJY-8206N VMQ silicone resin can be added as a base adhesive for two-component additive molding.)

Compared with other silicone potting compounds, add molding silicone potting compound has no by-products during curing, small shrinkage, good adhesion, can be hardened at room temperature or heated fast curing and a series of advantages, therefore, high-performance electronic potting typical applications in a wide range of fields.

3.2 What is the process of applying silicone potting agent manually

A. Stirring: use, please stir evenly A, and B (stirring bar can not be shared), so that the slightly precipitated filler is evenly dispersed in the glue.

B. Weighing: A agent and B agent are taken in the ratio of 3:10 by weight, A agent and B agent are mixed and stirred well after mixing.

C. Oxygen removal: the mixture should be vacuumed (≤ -0.1Mpa) to remove the air bubbles (the equipment of the glue filling process in the machine pipeline under the state of fully closed, the mixture does not need to deoxidize).

D. Pouring: Pour the adhesive into the parts to complete the potting operation (potting should be kept dry and clean the surface of the parts and mixing containers before, and it is recommended that the pouring device in the 70-80 ℃ baking 1 ~ 2 hours).

E. Curing: Cure the potted product at room temperature.

Precautions

When the two-component silicone potting compound is being constructed, it is necessary to mix the AB component separately, and then put the B component into the A component and mix it fully again. If there is uneven mixing in any process, it will lead to poor quality of the hardened product, and even change the performance of the upper and lower layers of the hardened product.

3.3 What are the advantages of the potting agent bonding method

Silicone potting compound fast curing can be achieved after sealing, bonding, waterproofing, shockproofing, electrical insulation, heat-resistant, flame-retardant, etc., to form a soft pliable rubber for the protection of sensitive component. To achieve this mechanical strength performance, the quality and construction process have great requirements. When using silicone potting compounds, both manual and mechanical potting can be used. Experienced users will choose manual bonding, if not necessary will not use machinery to bond.

(1) The advantage of manual bonding is that the pressure is more widely distributed. In the casting process, the stress distribution of the potting adhesive is wide, which is stronger than mechanical bonding; at the same time, the bonding strength and stability of the adhesive are improved, better performance is achieved, and it is more economical and cost-saving.

(2) Compared with mechanical bonding methods, hand bonding is less costly and not slower. It can bond to a wide variety of materials, resist corrosion and protect from the elements. It does not expand rapidly even at high temperatures and can work well.

(3) There are no strict requirements for bonding materials. When using potting adhesive, in addition to the base surface needing to be processed in advance, it can also be bonded with materials that are not so easy to bond.

3.4 How to solve the problem of potting adhesive not curing

3.4.1 Why does the potting compound not cure

(1) The electronic scale is not accurate enough, resulting in incorrect AB agent content. When the A agent is too much and the B agent content is too little, fast curing will not happen properly.

(2). The curing time is not long enough and the next step is rushed. Or the curing temperature is too low so that the adhesive can not be fully cured. Especially in winter, the temperature is low and the curing time needs to be extended.

(3). Adhesive has expired, after the shelf life may be quality change, and can not be used normally. Check the expiration date before use, do not use expired products.

(4). In the process of use, it may be in contact with compounds such as nitrogen, phosphorus, or sulfur, and may also be in contact with unsaturated polyester or polyurethane products, resulting in "poisoning".

3.4.2 How to solve

(1) Regularly calibrate the electronic scale, accurately weigh the AB components, and then mix.

(2) In winter, the adhesive can be preheated or heated to cure.

(3) Handle the adhesive according to the shelf life and use products with a shelf life to avoid waste.

(4) Keep the working environment safe and away from products that will react with silicone potting compounds.

(5) Store according to the instructions in the manual and keep good ventilation.

3.5 How to avoid air bubbles

(1) It is recommended to use products with low viscosity and long operating time so that air can be expelled before the material cures.

(2) Keeping the curing temperature below 45℃ to avoid too high a temperature that prevents air bubbles from being discharged.

(3) Determining the solidify ratio to regulate the cure speed. The amount of curing agent as well as changes in ambient temperature and humidity have a great influence on the curing speed. Increasing the amount of curing agent will accelerate the cure reaction. Therefore, the curing speed can usually be regulated by increasing or decreasing the amount of curing agent. The generally recommended dosage is between 10:0.8 and 10:1.2 (mass ratio). If it is necessary to change the ratio, it should be applied after a simple experiment of changing the mixing ratio.

4. What factors should be considered when using organic silicone potting compounds

(1) The pressure situation. This parameter is very important, related to the ability to resist external forces and the length of service life. Most silicone sealants have good stress distribution and can withstand a certain range of pressure with little problem.

(2)The environment of use. Whether there is corrosion, humidity, etc., are able to effectively resist these external factors, so that the adhesive works properly.

(3) In addition, the performance of the material must be considered to see if the silicone soft pliable rubber and substrate can be bonded together. The substrate should be effectively treated beforehand to remove impurities or polished to improve bonding strength.

5. What are the typical applications of silicone potting compounds

5.1 Applications of silicone potting compound in electric power

Silicone potting compound has good thermal insulation performance, a low coefficient of thermal expansion; waterproof performance can make the curing gel, prevent the entry of condensation water; corrosion resistance to ensure long-term operation in the acid, salt environment; excellent aging resistance to make its service life of fifty years. Therefore, widely used in cable accessories insulation, moisture sealing, environmental protection, anti-corrosion, encapsulation, and bonding.

5.2 Applications of silicone potting compound in automotive electronics

Silicone potting compound is used on a variety of control modules, and electronic equipment as a whole for potting to meet the basic requirements of dampproof, dirt, and corrosion resistance. Silicone's typical applications in automotive electronics include bonding and sealing agents, potting adhesives, gels, insulating coatings, thermally conductive adhesives, and other materials. These materials are used for the protection of engine control modules, ignition coils and ignition modules, powertrain modules, brake system modules, exhaust emission control modules, electrical systems, lighting systems, various sensors, connectors, power supplies, and more. Silicone potting materials are used on various control modules for overall and generalized potting of device typical applications that need to meet the basic requirements of dampproof, dirt and corrosion resistance.

5.2.1 How thermally conductive silicone keeps car battery temperature stable and safe

The power battery field of thermal conductivity encapsulation forces the battery system to the outside world to transfer heat in three ways: heat conduction, convection heat transfer, and radiation heat transfer. That is to say, in a limited environment, the main way of heat transfer between the battery cell and the outside world is heat conduction. At present, there are four main cooling methods for most new energy vehicles: direct cooling, air/water mixed cooling, low-temperature radiator cooling, direct air cooling, etc. The above cooling methods utilize heat conduction to transfer heat from the battery cell to the outside world.

The above cooling methods utilize heat conduction to transfer heat from the electric core to the cooling region quickly and efficiently, and ultimately achieve cooling at the cooling operating temperature. In this heat dissipation process, thermally conductive silicone is the bridge for heat transfer between the power battery system and the cooling area. Most of the heat from the battery is transferred to the cooling area through the thermally conductive silicone. Therefore, the efficient heat transfer of the thermally conductive silicone gel is very important.

Thermally conductive silicone gel has insulating properties while conducting heat. Since the raw material of thermally conductive silicone is composed entirely of insulating materials, it harmlessly adds a very good advantage, namely, its own insulation, which can effectively prevent the battery monomer in the automotive battery system from generating a strong voltage due to excessive current, which can damage the normal use of the power battery system, and avoid failures such as short circuits. Heat dissipation and cooling through heat transfer means longer battery life. When the power cell is under effective heat transfer and cooling, it always maintains a constant and proper temperature. The service life of the diaphragm and the electrolyte inside the battery will be greatly extended, and the battery will last longer.

5.3 Application of silicone materials in the power supplies industry

With the continuous development of social and economic development, in order to ensure the performance of power supplies equipment in the typical applications of the stability and durability of the major industries, to eliminate the natural environmental factors (wet weather, salt spray, dust, vibration, heat, etc.) on the power supply equipment, resulting in reduced reliability of the equipment, the power supply industry put forward more stringent requirements. Silicone is a typical technology-intensive, high value-added product, because of its unique wet weather, hydrophobic, electrical insulation, high and low-temperature resistance and other excellent performance, in the field of power supply industry has been widely developed and applied.

5.4 Applications in the manufacture of transportation tools

Silicone potting compound is not only good water resistant, but it also has lubricant resistance. It can be used in water as the medium of the system, and can also be used in the lubrication system. Especially in the field of transportation tool manufacturing, can often be used, and transportation equipment has a very good bond sealing.

Mainly used in automotive engines, windshields, door and window frames, reflectors, exhaust pipes, lights, instruments, containers, trunks and other equipment susceptible to water spray molding gaskets and adhesive seals. Silicone sealant has excellent water resistance and lubricant resistance and can be used in pumps, water tanks and other water-based systems, as well as engines, gearboxes, cam boxes, transformers, hydraulic systems and other lubricating oil as the medium of the system.

5.5 Building energy saving

Silicone potting sealant in the building doors and windows curtain wall typical applications mainly includes insulating glass secondary sealing, curtain wall structure, weather sealing and doors and windows waterproof weather sealing three aspects. The quality of silicone sealant not only affects the safety of the entire building door, window and curtain wall structure but also affects whether the building meets the requirements of energy saving and environmental protection.

6. XJY Silicone - the silicone potting compound raw materials preferred suppliers

Silicon potting compound not only has cold resistance, thermal shock resistance, and resistance to ultraviolet radiation but also has high light transmittance, low moisture absorption, and insulating properties. With the continuous development of society, silicone potting compound is gradually being widely used. How to make your products occupy the market faster?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our hydrogenated silicone fluids and vinyl silicone fluids are available in low-viscosity or customized viscosity solutions according to your typical applications requirement specifications (adhesives/potting compounds/sealants).