As we entered the 20th century, motor technology continued to evolve. Permanent magnet motors, with their high efficiency and high power density, began to gain prominence in fields such as aerospace and electric vehicles. Meanwhile, with the development of electronic technology and control theory, variable frequency speed control motors emerged. These motors can flexibly adjust their speed according to load requirements, significantly improving motor operational efficiency and energy-saving effects, and are widely applied in equipment such as air conditioners and fans. What are the advantages of silicone resin in motors?

Silicone resin offers numerous significant advantages. First, it exhibits exceptional heat resistance, with weight loss of only 2%–8 % even after 24 hours of heating at 250°C, far outperforming other common organic resins. Second, it boasts superior electrical insulation properties, maintaining high insulation resistance and low dielectric loss across a wide range of temperatures and frequencies. Additionally, silicone resin has excellent weather resistance and chemical resistance, does not yellow easily even under intense UV radiation, and possesses water repellent properties, salt fog resistance, and mold-resistant properties. It also has strong resistance to acids, alkalis, and other chemicals and is not easily corroded. These advantages make silicone resin widely applicable in various fields such as electronics and electrical engineering.

There are three aspects to introducing silicone resin:

- What are the advantages of silicone resin?

- How are silicone resins applied in motor systems?

- How can silicone MQ resins be improved?

1. What are the advantages of silicone resin?

With its unique molecular structure, it demonstrates outstanding comprehensive performance and has been widely adopted in industrial applications. The following analyzes its core advantages from a materials science perspective:

(1) Excellent thermal stability

Silicone resin can operate stably at high temperatures of 200-250°C for extended periods and can withstand short-term temperature peaks of up to 300°C. By incorporating heat-resistant reinforcing fillers, its temperature resistance limit can be extended beyond 800°C. This property makes it highly effective in high-temperature equipment protection applications, such as coatings for industrial furnace interiors and components in automotive exhaust systems.

(2) Enhanced environmental resistance

The material's stability stems from a dual protective mechanism: the high bond energy of the Si-O chemical bond (452 kJ/mol) effectively resists free radical reactions triggered by UV radiation; the low absorption characteristics of methyl groups in the molecular structure for UV light spectra (<95% transmittance in the <300 nm wavelength band) ensure that the coating maintains durability for over 20 years under outdoor exposure conditions. It has now become the preferred solution for photovoltaic module encapsulation materials.

(3) Smart Dielectric Properties

Within the temperature range of -50°C to 200°C, the dielectric constant remains stable at 2.8–3.2 (1 MHz), with a dielectric loss tangent ≤0.001. Even in a high-humidity environment of 95% RH, the volume resistivity remains at the 10¹⁵ Ω·cm level. This wide-range stability makes it indispensable in applications such as 5G base station insulation encapsulation and high-voltage motor winding protection.

(4) Wide temperature range adaptability

Through copolymer modification technology, the glass transition temperature can be controlled within the range of -120°C to +150°C. Modified resins used in Arctic research equipment maintain an impact strength retention rate of >85% at -80°C while simultaneously meeting short-term thermal load requirements at 150°C. This extreme environment adaptability has been applied to spacecraft external protection systems.

(5) Controllable wetting performance

By adjusting organic groups (R/Si = 1.2–1.8), a gradient water repellent surface with contact angles of 110°–150° can be achieved. For different application scenarios, building curtain wall coatings achieve self-cleaning functionality (contact angle > 140°), while medical device coatings are designed with moderate wettability (contact angle 90° ± 5). However, surface grafting modification is required for high-temperature steam environments (>120°C).

(6) Selective Permeation Structure

The unique free volume fraction (FFV ≈ 0.15) confers excellent gas permeability selectivity to the material. The CO₂/CH₄ separation coefficient reaches 35 (30°C, 1 MPa), outperforming traditional polymer materials in biogas purification membrane applications. In the medical field, oxygen permeability can reach 5000 Barrer, providing an ideal substrate for silicone-based dressings.

(7) Interface control capability

Surface tension as low as 21 mN/m (25°C), a 40% reduction compared to conventional resins. Adding 1–3% organosilicon additives to coating systems can reduce system viscosity by over 30%, achieving a mirror-like flow leveling effect (surface roughness Ra < 0.1 μm). This property plays a critical role in semiconductor packaging materials and precision electronic coatings.

(8) Chemical Protection Matrix

Forms a three-dimensional crosslinked network structure (crosslink density 300–500 mol/m³), maintaining chemical stability across a pH range of 1–13. After 1,000 hours of salt spray testing, the coating adhesion retention rate exceeds 90%. A specially developed solvent-resistant formulation can withstand strong polar solvents such as DMAC and NMP, and has been applied in the field of lithium-ion battery separator coating.

This material system is evolving toward functionalization and intelligence. Recent research achievements include self-healing organosilicon elastomers (healing efficiency >95%) and photothermal responsive coatings (solar energy absorption rate >90%), continuously expanding its application boundaries in cutting-edge fields such as new energy and biomedicine.

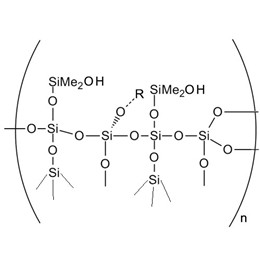

XJY-8205 MQ resin is the product of the co-hydrolysis of tetraalkoxysilane (Q unit) and trimethylalkoxysilane (M unit). It can be used as a reinforcing material in the encapsulation material and has the effect of anti-vibration and insulation.

2. How are silicone resins applied in motor systems?

As a key material in modern motor engineering, organosilicon resins have achieved multi-functional integration through molecular structural innovation, with their applications evolving from basic insulation to intelligent protection. The following technical breakthroughs in motor systems are analyzed from a materials engineering perspective:

2.1 Construction of intelligent insulation systems

(1) Three-dimensional composite insulation technology

Using a gradient impregnation process (vacuum pressure impregnation + rotational curing), the pore filling rate inside the coil exceeds 99.8%, and the dielectric loss factor is reduced to 0.0003 (at a field strength of 1 kV/mm). After aging at 180°C for 2,000 hours, the breakdown voltage retention rate of the H-class insulation system exceeds 95%, representing a 40% improvement over traditional epoxy systems.

(2) Nano-composite coating technology

Modified using SiO₂@ZrO₂ core-shell structured nanoparticles (particle size 50 nm), the surface insulation coating achieves a hardness of 4H (pencil hardness) and arc resistance >180 s (ASTM D495). Under a 10 kV/mm electric field, the surface leakage current is <0.1 μA/cm², successfully applied to the stator protection of high-speed permanent magnet motors (20,000 rpm class).

2.2 Development of Advanced Insulation Materials

(1) Ultra-thin Mica Composite Materials

Innovatively developed 12 μm-thick ultra-thin mica tape (mica content 65%), combined with organosilicon resin rheological modification technology, achieving interlayer bonding strength >8 N/mm (IEC 60371 standard). In 10 kV traction motors, the main insulation thickness was reduced by 30%, and temperature rise decreased by 15 K.

(2) Fiber-reinforced structural materials

Using three-dimensional woven glass fiber preforms (volume fraction 55%), formed via organic silicon resin RTM process, a composite slot wedge material with a thermal conductivity of 1.2 W/(m·K) was produced. In 5MW-class wind turbines, the temperature drop at the winding ends reached 20°C, with mechanical strength retention rate (200°C/5000h) >90%.

2.3 Functionalized Encapsulation System

(1) Adaptive Encapsulation Technology

A thermally expandable encapsulation adhesive with a controllable coefficient of thermal expansion (CTE adjustable between 80-150 ppm/°C) was developed to match different metal housings. In electric vehicle drive motors, it achieved 1,000 cycles between -40°C and 180°C without cracking, with thermal conductivity improved to 0.8 W/(m·K), representing a 300% increase over traditional products.

(2) Electromagnetic Compatibility Encapsulation

Using ferrite/silicone composite technology (permeability μ=5), we have developed electromagnetic shielding encapsulation materials with shielding effectiveness >45 dB at 1 GHz. When applied to precision servo motors, EMI radiation values are reduced to below CLASS B standards.

2.4 Structure-Function Integrated Bonding

(1) Corona-Resistant Bonding System

Using silazane modification technology, the adhesive achieves an aging lifespan exceeding 10,000 hours at 200°C under partial discharge (PDIV > 2 kV) conditions. Successfully applied to high-speed motor rotor laminate bonding, achieving dynamic balance accuracy of G1.0 grade at 18,000 rpm.

(2) Intelligent Sealing System

Developed humidity-responsive sealant (with controllable water absorption expansion rate of 5%-15%), automatically adjusting sealing pressure in a 95% RH environment. Applied to deep-sea operation motors (1,000m class), achieving IP69K protection rating and reducing vibration noise by 8 dB(A).

This technology system has formed a complete solution: in the Tesla Model 3 drive motor, the use of an organic silicon insulation system has increased power density to 5.8 kW/kg; Siemens offshore wind turbines use nano-insulation coatings to achieve 25 years of maintenance-free operation. With the industrialization of new diphenyl silicone resins (temperature resistance upgraded to 220°C) and conductive silicone electromagnetic shielding materials, silicone resins are redefining the technical standards for next-generation high-efficiency motors.

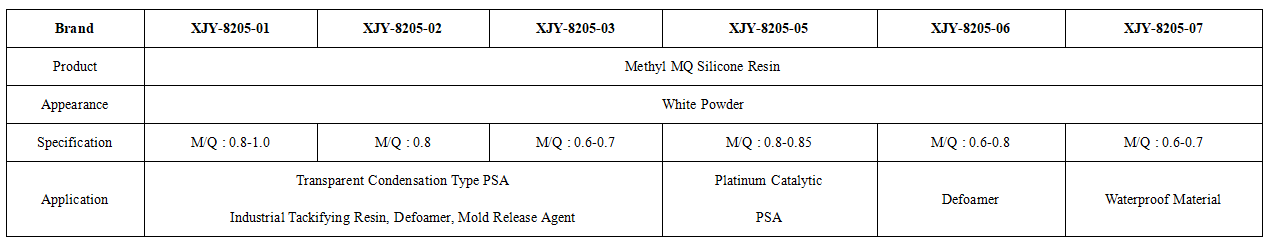

3. How can silicone MQ resins be improved?

MQ resins(sodium silicate and various chlorosilanes were used as starting materials), with their excellent release properties, heat resistance, weathering resistance, and adhesion, water repellency, offer broad application prospects in the electronics field. Through modification and optimization, MQ resin can further enhance motor performance to meet the needs of various industries (also has liquid form). How to enhance product competitiveness? More data plesae contact us ,we also has silicone oils.

XJY Silicone is one of China's leading manufacturers of organic silicon MQ resin and VMQ organic silicon, with over 30 years of R&D and manufacturing experience in the organic silicon industry, holding more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the electronics industry and provide diversified customized solutions for qualified industrial users. In addition to these advantages, silicone resins can also be modified to exhibit non-reactive properties, making them suitable for applications where chemical stability is crucial. They can also be formulated to be pressure-sensitive adhesives or binders, allowing for easy application and strong adhesion in various industrial processes. For example, in the production of films and paints, silicone resins can be used to create water-repellent coatings that protect surfaces from moisture and other environmental factors. They can also be combined with vinyl or acrylate materials to enhance their performance in specific applications. By leveraging these properties, silicone resins can be tailored to meet a wide range of industrial needs, from protecting electronic components to improving the durability of coatings and adhesives.

![]()