The market for organosilicon film formers in the cosmetics industry is showing a steady growth trend. In the cosmetics industry, organosilicon film formers are widely used in products such as foundation, sunscreen, and makeup. Their unique properties, such as water resistance, breathability, flexibility, and improved skin feel, make them a key component in enhancing the performance of cosmetics. What factors influence the silicone film-forming agnet?

Silicone film-forming agents have a significant impact on the cosmetics industry. They can significantly enhance product performance, such as improving durability, waterproofing, and sweat resistance, enhancing skin feel, and improving color effects, meeting consumers' demand for high-quality cosmetics. In terms of formulation innovation, their excellent compatibility with various ingredients optimizes the performance of cosmetic films while reducing the usage of other ingredients and lowering costs. Additionally, they drive growth in the cosmetics market, particularly in sunscreen and makeup, and skin care products, hair care products.

There are five aspects to introducing silicone film agents:

- How are film-forming agents classified?

- How to compare the film-forming effects of different film-forming agents?

- How does molecular weight affect MQ film-forming performance?

- How does the combination of “soft” and “hard” components affect film-forming performance?

- How to improve silicone film-forming agents?

1. How are film-forming agents classified?

(1) Classification by solubility

Oil-soluble film-forming agents: These can dissolve in oil-based solvents and are used in oil-based systems or formulations requiring good compatibility with oils.

Water-dispersible film-forming agents: These can disperse in water and are suitable for water-based or water-in-oil (O/W) sunscreen formulations, making them the most commonly used type currently.

(2) Classification by chemical structure

Vinyl pyrrolidone derivatives: Possess excellent film-forming performance and skin affinity, with good flexibility of the film after formation.

Acrylic polymers: Form films quickly, with good hardness and abrasion resistance, and their film-forming properties can be adjusted by modifying the polymer structure.

Organosiloxane-based: They have excellent water resistance, breathability, and a smooth texture, and after forming a film, they provide the skin with a good dry and soft feel.

Polyurethane-based: Forms a tough, abrasion-resistant film with good adhesion to the skin, and the film's flexibility and hardness can be adjusted.

Polyester-based: Has stable film-forming properties and good compatibility with other ingredients, forming a uniform, continuous film on the skin surface.

2. How to compare the film-forming effects of different film-forming agents?

Five different types of film-forming agents—vinyl pyrrolidone derivatives, acrylic polymers, organosiloxanes, polyurethanes, and polyesters—were added at different concentrations to an O/W sunscreen emulsion formulation to prepare test samples. An emulsion without added film-forming agents served as the blank control group. Using a sun protection factor analyzer and a UV-visible absorption spectrometer, the SPF values of the samples were tested using an in vitro method to study the effect of film-forming agents on SPF enhancement performance and water resistance.

The results showed significant differences among different film-forming agents in enhancing the performance of O/W sunscreen systems.

(1) In terms of SPF enhancement effects

PVP-based and acrylic polymer-based film-forming agents showed significant enhancement. At a 2% addition level, A2 achieved an SPF enhancement rate of 47%, while acrylic polymer-based agents exceeded 30% enhancement at 2–3% addition levels. This is attributed to their ability to strengthen the emulsion interface strength and promote uniform distribution of sunscreen agents. Silicone-based agents exhibited weaker enhancement effects, with fluorinated C3 showing slightly better performance than C1 and C2, as C1 and C2 exhibit poor compatibility in the formulation; polyester and polyurethane types have minimal and similar effects on SPF values.

(2) In terms of their impact on absorption curves

PVP-based and acrylic polymer-based agents significantly enhance absorption in the UVA and UVB bands. Silicone-based agents only show a noticeable shift in the absorption curve for C3, while polyurethane and polyester-based agents only enhance absorption in the UVB band. This is related to how each type of film-forming agent improves water resistance, rheological properties, and their own characteristics.

(3) In terms of water resistance

PVP-based, certain acrylic polymer-based, and polyurethane-based film formers exhibit good performance, while C1 and polyester-based film formers have slightly poorer E water resistance, and C3 has good water resistance. This is attributed to the chemical structure of the film formers, such as the long-chain alkyl groups in PVP-based film formers enhancing water resistance, the hard and brittle nature of C1 and E film formers making them prone to cracking, and the fluorinated modified groups in C3 enhancing water resistance.

3. How does molecular weight affect MQ film-forming performance?

Twenty-one MQ silicone resins were screened, and solid film-forming agents were formulated into 15% and 40% solutions of cyclopentasiloxane. Liquid film-forming agents were diluted to the same concentration based on solid content. Through various performance tests, the molecular weight of each film-forming agent and its distribution state, film-forming properties, film-forming time, hydrophobicity, sweat resistance, oil resistance, breathability, and other performance characteristics were studied. The results showed:

(1) Molecular weight:

Most MQ silicone resins have molecular weights ranging from 4,000 to 9,000 Da, with a PDI of 1 to 3, close to 2, and a relatively wide distribution.

(2) Film-forming brittleness:

When the molecular weight is between 4,000 and 8,200 Da, film-forming brittleness exhibits a linear relationship with molecular weight; as molecular weight decreases, brittleness also decreases.

(3) Film formation time:

Film formers with molecular weights of 7,000–8,200 Da exhibit high film formation brittleness and short film formation times; those with molecular weights of 4,000–7,000 Da exhibit reduced film formation brittleness and extended film formation times. Additionally, when samples have similar properties and comparable molecular weights, those with higher PDI values exhibit longer film formation times.

(4) Permeability rate:

Samples with high permeability rates have lower molecular weights, lower film brittleness, and longer formation times; samples with low permeability rates have higher molecular weights and higher film brittleness.

(5) Hydrophobicity, sweat-repellency, and oil-repellency:

Most samples cannot simultaneously exhibit both hydrophobicity and oil-repellency, but samples Q, H, I, S, and T exhibit relatively balanced performance. Between 4000 and 8000 Da, hydrophobicity and oil-repellency increase with rising molecular weight; above 8000 Da, the trend changes.

Comprehensive performance: At high molecular weights, film-forming brittleness is strong, film formation time is fast, and breathability is low; when the molecular weight is low, the opposite is true. Between 4000 and 8000 Da, hydrophobicity and oleophobicity increase with increasing molecular weight. When the molecular weight is around 8000 Da, the hydrophobicity of MQ resin is relatively low, but it increases with further increases in molecular weight, while oleophobicity decreases with increasing molecular weight.

4. How does the combination of “soft” and “hard” components affect film-forming performance?

Current long-lasting makeup technologies primarily rely on “film-forming agents,” but lack universal formulation guidelines. The “soft” + “hard” formulation strategy focuses on the interactions between non-volatile components. Understanding the intrinsic material properties of ‘soft’ and “hard” non-volatile mixtures can help predict and optimize the durability of makeup films.

The study selected “soft” components (silicone polyether emulsifiers, SPE) and “hard” components (silicone acrylate copolymers) for investigation, preparing mixtures at different ratios and conducting tests.

Testing methods and results: Through visual assessment and transmission electron microscopy observation, it was found that silicone acrylates are compatible with certain silicone polyether emulsifiers (SPE) but incompatible with others; the viscoelasticity, film properties (hardness and viscosity), flexibility, and crack resistance of compatible mixtures, it was found that the ratio of “soft” to “hard” components affects these properties; sebum/oil wear tests and contact transfer tests were conducted, and the results indicated that if sebum is miscible with non-volatile components, it reduces the ‘hard’ to “soft” ratio, weakening the binding force between pigments and skin; selecting components with low miscibility with sebum can reduce the negative effects of sebum.

Emulsifier D has good compatibility with silicone acrylates and the highest degree of immiscibility with synthetic sebum oil, thereby providing the formulation with optimal sebum resistance. This suggests that when selecting soft components for film-forming agents, choosing components with good compatibility with the film-forming agent but poor compatibility with sebum can result in a more long-lasting makeup application.

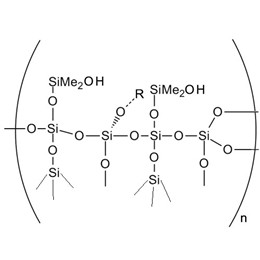

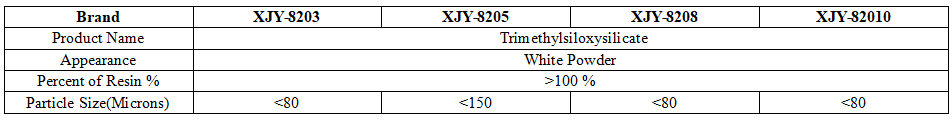

XJY-8203/8205 Methyl MO Silicone Resin

XJY8203/8205 is a solid silicone powder, this silicone can form continuous layer. The smooth feel it creates provides excellent water resistance and can be used in a variety of skin care formulations. It also has UV protection and can be used in sunscreen products. There are also different organic solvent can match.

5. How to improve silicone film-forming agents?

Different from natural appearance, silicone film-forming agents offer numerous significant chemical properties and mechanical properties. First, they exhibit excellent weather resistance, maintaining stability under harsh conditions such as UV exposure, high temperatures, and humidity, water binding properties, without aging, cracking, or discoloration because of functional groups. Second, their low surface tension provides excellent wetting and spreading properties on object surfaces, enabling uniform coverage and the formation of a continuous covering film. Silicone film former can be used in the pharmaceutical industry( in drug substance, drug release, drug delivery, wet granulation, yield tablets). How can the performance of silicone film-forming agents be improved?

Xinjiayi Silicone is one of China's leading manufacturers of silicone MQ resins and VMQ silicones, with over 30 years of R&D and manufacturing experience in the silicone industry, holding more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the cosmetics industry and provide diverse customized solutions for qualified industrial users.

![]()