A seal is a specialized material serving multiple critical functions in modern applications. These polymer compounds offer essential bonding and sealing properties, primarily used for waterproofing and vibration dampening across various industries.

Compared with other adhesives, silicones are compounds composed of elements such as carbon, hydrogen, oxygen, and silicon, which contain Si-C bonds and have at least one organic group directly attached to the silicon atom. These compounds are widely used in many industries due to their excellent physicochemical properties, and are also suitable for use in silicone sealants, so what can be called silicone sealant?

A silicone sealant represents a high-performance sealing solution that combines versatility with durability. Using Polydimethylsiloxane as the primary component, these materials are enhanced with crosslinking agents, fillers, plasticizers, coupling agents, and catalysts. When mixed under vacuum conditions, they form a paste that cures at room temperature by reacting with atmospheric moisture, creating a flexible and resilient seal. They are also high-temperature silicone sealants.

Here's some information about it:

- How to classify silicone sealant?

- What are the advantages of silicone sealants?

- What are the features of silicone sealant?

- What are the applications of silicone sealants?

- What are the problems of silicone sealant?

- How to make silicone sealant performance better?

1. How to classify silicone sealant?

Room temperature vulcanization (RTV) technology enables these sealing compounds to harden under greenhouse conditions. When exposed to moisture in an open environment, they undergo a cross-linking reaction to form a rubber elastomer. Based on the type of molecules released during curing, these products are categorized into several types: de-alcoholized, de-acetone, de-acidified, and de-ketone formulations.

![]()

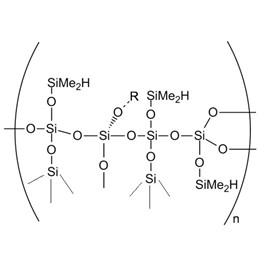

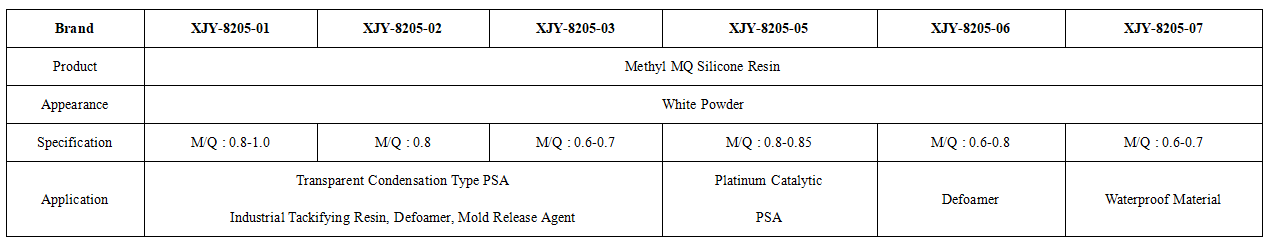

XJY-8205 MQ Resin Powder Silicone Methyl MQ Resin can be used as an industrial tackifying resin.

XJY-8207S/M Hydrogen MQ Resin can be used as a tackifier for silicone sealant.

1.1 Deacidification

Key Benefits:

- Competitive pricing compared to organic products

- Fast curing

- Catalyst-free version available

- Long shelf life

- Good transparency and clarity

- Bonding durability

1.2 Dealcoholation

Notable Features:

- Neutral curing

- Strong adhesion

- Economical

- Low VOC content, low odor, environmentally friendly

1.3 Deoximation

Primary Characteristics:

- Fast curing

- Low catalyst option available

![]()

2. What are the advantages of silicone sealants?

When compared to conventional organic products like polyurethane or acrylic sealants, modern silicone polymer sealing solutions offer distinct benefits:

(1) Triple the protection duration in similar applications, preventing early failure and reducing maintenance costs

(2) Superior stability - unlike organic polyurethanes that can revert to a soft state

(3) Enhanced long-term value versus traditional options

(4) Extended lifecycle with outstanding environmental resistance, effectively protecting against UV rays, ozone, precipitation, and extreme temperature fluctuations.

![]()

3. What are the features of silicone sealant?

(1) Temperature Performance

These silicone materials maintain stability across an impressive temperature range of -56 to 177°C (with brief exposure tolerance up to 204°C). Specialized formulations can even withstand sustained temperatures of 260°C (intermittent exposure to 315°C).

(2) Environmental Durability

Advanced silicone products offer exceptional resistance to UV radiation and weathering, effectively preventing common issues like hardening, cracking, and brittleness.

(3) Chemical Resistance

These sealant material maintain their integrity even after prolonged exposure to various chemicals and environmental pollutants.

(4) Adhesion Properties

Modern synthetic compounds demonstrate excellent bonding capabilities with numerous industrial materials, including:

- Glass and ceramics

- Wood surfaces

- Painted substrates

- Various metals

- Multiple plastic types

(5) Electrical Characteristics

Engineered for versatility, these common silicone products suit diverse electrical and electronic applications, particularly in components experiencing thermal cycling.

(6) Fire Safety

These sealing-grade silicone materials offer inherent fire resistance. Many formulations meet strict UL flammability standards.

![]()

4. What are the applications of silicone sealants?

(1) Building Envelope Protection

- Curtain wall weather sealing

- Glass curtain wall systems

- Aluminum composite panel installation

- Stone cladding protection

(2) Interior Applications

- Joint sealing between various materials

- Home improvement projects

- Decorative element installation

(3) Construction Material Bonding

- Concrete and cement structures

- Natural stone and marble

- Metal framework

- Wood components

- Anodized and painted aluminum surfaces

![]()

5. What are the problems with silicone sealant?

The following Deketoxime-type products as an example.

5.1 How do silicone adhesive sealants achieve curing performance?

One-component condensation curing silicone rubber products are cured using moisture in the air. Curing from the surface to the inside, usually at 25 ℃ and 50% RH conditions, one-component adhesive sealant 24h can be cured 3mm; it usually takes several days to form dry bonding surfaces and reach the inherent physical properties.

5.2 What are the differences in silicone sealants' surface drying time between winter and summer?

One-component condensation curing silicone rubber products, table drying and curing speed, and environmental temperature have a great relationship, winter humidity, low temperature, glue table drying curing speed is slow, summer humidity, high temperature glue table drying, clean surfaces curing faster.

![]()

5.3 How is silicone adhesive sealant temperature resistant?

General silicone temperature ranges from -40 ℃ to 20O0C, the long-term use of temperature does not exceed 150 ℃, special high-temperature adhesive red silicone temperature ranges from -40 ℃ to 250 ℃, long-term use of temperature does not exceed 180 ℃. Temperature resistance and whether the colloid is fully cured have a great correlation; if not fully cured when heating will produce bubbles, cracking, smoking, and other undesirable phenomena.

5.4 Why is white silicone adhesive sealant easy to yellow?

Deketone-type silicone contains ketoxime crosslinking agent, amino silane tackifiers, and catalysts. In long-term ultraviolet irradiation or a high-temperature environment, due to the oxidation of the amino group or some chemical reactions of the catalyst, it may cause surface yellowing. To improve the yellowing phenomenon, special formulations are needed, such as solar silicone, which has good anti-yellowing properties. Dehydrated silicone, in the case of not being fully cured, is not involved in the reaction of the titanate catalyst because of its own yellow color. In hot conditions, the colloid will display as yellowing.

5.5 Why does silicone sealant have a viscosity difference between winter and summer?

The viscosity of the glue will change with the temperature; high-temperature viscosity is reduced in summer, and winter is just the opposite, but it will be within the qualified range.

5.6 Why does it produce the "air dew" phenomenon in the closed system?

Deketoxime silicone sealant can be used in closed systems, such as lamps, headlights, and other industries, sometimes in the glass on the inner surface of a phenomenon similar to "air dew", which greatly reduces the transparency of the glass greatly reduced, affecting the glass transmittance and aesthetics. This is due to the closed system of sizing, de-aliphatic silicone curing the release of butanone oxime can not be discharged into the atmosphere in a timely manner and gathered attached to the surface of the glass caused by; the use of de-alcoholized silica gel can be more easily avoided this kind of aerosol phenomenon, because of its curing release of the products of the alcohols, at room temperature for the gas, will not be gathered adhering to the surface of the glass.

![]()

5.7 How to improve the silicone sealant's curing speed?

For greater than 6mm curing thickness, it is recommended to use 2 times the amount of silicone sealant. Improving the temperature and humidity can accelerate the curing speed of the product, but the temperature should not be more than 50 ℃; increasing the effect of humidity is better than raising the temperature!

5.8 How to remove silicone sealant?

Before the curing of silicone, you can use a putty knife to scrape off the uncured paste to clean surfaces, and then use petroleum ether to clean the residue. After the silicone curing, First, you can use a knife or razor to mechanically scrape off as much silicone as possible, and then use a solvent to remove all kinds of oil residue or silicone. Soak the silicone in such solvents overnight to let it dissolve before cleaning. After these steps, the product can be tack-free again.

Conclusion:

Understanding these aspects of silicone sealants is crucial for achieving optimal results in various applications. While they may present certain challenges, their superior performance characteristics and longevity make them an excellent choice for many sealing applications. Proper selection, preparation, and application techniques are key to maximizing their effectiveness.

6. How to make silicone sealant perform better?

Silicone sealant (silicone adhesives) is widely used for multi purpose in daily life, including the automotive electronics industry (including automotive accessories, lamps, lathe sealing, etc.), household appliances (such as refrigerators, kettles, induction cookers, microwave ovens, ovens, electric irons, etc. need to use silicone bonding sealant), lamps, tube, engineering machinery, control module bezel sealing and waterproofing, circuit board components are fixed, fixed wires and industrial setting. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw products can meet the needs of silicone sealants and support the provision of diversified customized solutions.