The current sunscreen market is seeing continuously evolving consumer expectations, with users not only focusing on SPF/PA values but also prioritizing broad spectrum protection, product texture, longevity, water resistant properties, sweat resistance, mildness, transparency, and aesthetic appeal. Relying solely on traditional lotion-based matrices and film-forming agents is no longer sufficient to balance superior sun protection with an excellent user experience. Why add MQ silicone resin to sunscreen?

Silicone sunscreen resins have strong compatibility, able to co-solubilize with oil phases/silicone oils/emulsions, and also assist in stabilizing the suspension of solid powders such as zinc oxide. For UV absorbers and nano-TiO₂/ZnO, through interfacial wetting and encapsulation, they inhibit aggregation, precipitation, and migration, ensuring the sunscreen gel spreads evenly on the skin and reducing “sunscreen gaps” on the skin’s surface for broad-spectrum UVA/UVB and even infrared protection. By imparting a hydrophobic protective layer on the surface, the photodegradation, oxidative degradation, and ultraviolet rays attenuation effects of sunscreen agents are significantly reduced, extending the product’s protective “half-life”—a must for outdoor activities and long sun exposure. Silicone resins lack allergenic groups in their structure, resulting in extremely low skin and mucous membrane contact reactions. They are generally non-irritating, non-toxic, and non-comedogenic, and perform better than conventional organic film-forming agents in percutaneous sensitization, acne-causing, and inflammatory tests, making them suitable for sensitive skin and acne-prone skin.

There are six aspects to introducing silicone sunscreen:

- What are the properties of silicone resins?

- Why choose MQ resin to add to silicone sunscreen?

- What Are the Advantages of MQ Silicone Resin?

- How to validate the efficacy of silicone resins?

- What is the trend of silicone resins in the sunscreen field?

- How to enhance the performance of cosmetic products?

1. What are the properties of silicone resins?

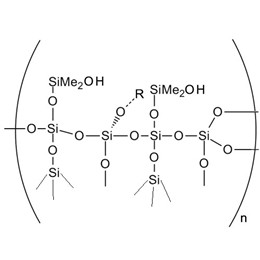

MQ silicone resin belongs to the silicone gel family, with its basic units composed of two types of siloxane units:

M unit (R3SiO1/2): trimethylsiloxyl.

Q unit (SiO4/2): tetraoxysilyl.

The M unit provides flexible organic functional groups, imparting hydrophobic, soft, and excellent skin-friendly properties to the material; the Q unit forms a three-dimensional crosslinked structure, imparting rigidity and excellent film-forming ability to the polymer. This integrated organic (M) and inorganic (Q) network structure enables MQ resin to achieve balanced performance that traditional organic resins cannot match, thus improving both appearance and application on the face and neck. Additionally, silicone resins can help adjust skin texture and the appearance of scars, promoting better aesthetics and enhanced healing outcomes.

Basic properties:

High transparency, low refractive index (no visible white cast even with high SPF)

Excellent thermal stability and weather resistance (UV, UVB, UVA, and even blue light resistance)

Significant hydrophobicity and oleophobicity

Outstanding film-forming ability and adhesion (broad-spectrum sunscreen protection)

Lightweight, non-greasy texture, no sticky feeling (ideal for daily makeup and cosmetics routine)

Silicone resins can further enhance sunscreen and sun care products. Silicone resins are a class of highly cross-linked organic polymers with a silicon-oxygen backbone and organic side chains (such as methyl or phenyl groups), combining the dual advantages of organic and inorganic materials. Typically, silicone resins, especially in UV Doux blue light, and UV Doux silicone advanced formulas (like UV Doux Gold), have the following core characteristics:

Highly networked three-dimensional cross-linking (dense molecular bonding)

Good molecular chain mobility, compatible in emulsions/oil phases or volatile silicone oils

Extremely low surface energy and excellent hydrophobic/oleophobic properties

Self-assembles into a dense film on the skin for maximum protection from UV rays

2. Why choose MQ resin to add to silicone sunscreen?

As living standards improve and people increasingly prioritize beauty and health, sun protection has become an indispensable part of daily personal care routines. Nowadays, broad spectrum, high SPF (SPF 50 PA), water-resistant, and non-greasy features are considered industry standards, demanded by customers looking for superior sun protection against harmful UVA/UVB rays, blue light, and infrared exposure.

For sunscreen products, in addition to core sunscreen agents (physical/chemical), other components such as film formers, dispersants, and texture modifiers directly impact product stability, user experience, and sun protection efficacy. Here, MQ silicone resin stands out due to its unique organosilicon structure, its compatibility with acne-prone skin, and superior performance, thus becoming an indispensable formulation choice for modern high-end broad-spectrum sunscreen products.

Silicone sunscreens are great for sensitive skin, around the eyes, and as a versatile solution for various sun protection needs.

To achieve optimal protective efficacy and user experience, sunscreen formulation relies on film-forming agents with the following properties:

Uniform dispersion and secure encapsulation of sunscreen agents (such as zinc oxide and chemical sunscreens), ensuring even distribution of all components, boosting SPF/PA and broad spectrum values, and minimizing gaps that lead to sunburn and damage.

Outstanding film-forming ability to create a dense yet breathable barrier, improving water resistance, sweat resistance, and overall durability against repeated sun exposure (outdoors, at the beach, or during sports).

Superior skin compatibility and a comfortable, non-greasy and non irritating texture that is easy to apply and remove (reapply is seamless).

Possesses physiological inertness to avoid skin allergies or irritation, thus reducing the risk of typical sunscreen problems for sensitive skin, combination skin, and acne-prone skin.

XJY-8203/8205 Methyl MO Silicone Resin

XJY8203/8205 is a solid silicone powder; this silicone can form a continuous layer. The smooth feel it creates provides excellent water resistance and can be used in a variety of skin care formulations. It also has UV protection and can be used in sunscreen products. There are also different organic solvents that can match.

![]()

3. What are the advantages of MQ silicone resin?

(1) Exceptional film-forming performance:

MQ silicone resin rapidly self-assembles on the skin’s surface to form a dense, uniform, continuous, and ultra-thin three-dimensional crosslinked film. This film can:

Significantly enhance the targeted retention and coverage of the sunscreen components on the skin and face, reducing the risk of “sunburn leakage” and improving SPF 50 PA and broad spectrum ratings.

Enhance the formulation’s water and sweat resistance, making it ideal for outdoor activities (swimming, running), ensuring prolonged and sustained sun protection.

Remain transparent and non-sticky after film formation, yielding a pleasant skin feel, perfect for layered makeup or silicone sunscreen and cosmetics application.

(2) Superior makeup retention and clear skin feel:

Traditional sunscreen film-forming agents are prone to breakdown from oil, light, or pollutants, reducing sunscreen efficacy. The MQ silicone resin film retains integrity even when exposed to high temperatures, UV rays (UVA, UVB, infrared), sweat, or environmental aggressors all day. The film does not oxidize, change color, or cause heavy buildup. Its lightweight, breathable, “silk-like” finish is highly favored in the beauty world.

(3) Superior water resistance and durability:

The unique siloxane structure of MQ silicone resin provides significant water resistance and oleophobic properties, leading to “waterproof” and “sweatproof” performance. It is fundamental to specialized water sports or high-exposure sunscreens, including long-lasting broad-spectrum formulas like UV Doux Gold and UV Doux Silicone.

(4) Broad miscibility and compatibility:

MQ silicone resin blends easily with other silicone oils, emulsions, organic/inorganic sunscreens, and diverse components, helping create stable, efficient, and creative formulations (including sunscreen gel, sticks, sprays, and innovative non-comedogenic, non-toxic forms that are gentle yet robust). This supports customers in finding the right product for their specific skin type and concern.

(5) Safe, non-irritating, reduces sensitivity risk:

Silicone is highly inert. MQ resin has shown practically no irritation or sensitization in safety tests. The gentle film shields the skin from harmful UVA/UVB rays, infrared, and even modern threats like blue light from screens, which can cause hyperpigmentation and early signs of aging/altered appearance. These advantages are especially embraced by sensitive and acne-prone skin sunscreen markets.

(6) Silky texture and soft glow:

MQ resin provides a unique silk-like smoothness, improving spreadability and appearance without a white cast or “drying out.” Its transparency and light diffusion properties reduce the heavy effect often seen in traditional mineral (zinc oxide, titanium dioxide) formulas, yielding softer makeup looks and an enhanced, natural finish suitable for daily cosmetics routines.

4. How to validate the efficacy of silicone resins?

(1) Formulator Feedback:

Most formulators agree that silicone sunscreen products with silicone resins offer higher SPF and broad spectrum protection, with a luxurious, non-greasy texture. They address typical sunscreen problems like stickiness, patchiness, and whitening issues, which can cause acne or discomfort when quantity and application are not optimal. Silicone resins allow for flexible formulation in diverse forms (gel, cream, stick, powder), supporting creative adjustment for unique customer needs.

(2) Testing and Validation:

Numerous third-party validation studies (e.g., water/sweat resistance retention tests, SPF dynamic retention) consistently show that silicone resin film-forming formulations outperform traditional products for indicator stability, film layer density, and mimicking UV Doux Blue Light and UV Doux Gold performance in sun exposure tests.

(3) User Experience:

Customers report a brush head, refreshing feel, no residue, and easy cleansing—a must for people who reapply or layer with makeup. These pleasant qualities increase repeat day-to-day use and continue to raise positive reviews and repurchase rates.

5. What is the trend of silicone resins in the sunscreen field?

(1) International Brand Trends:

Global leaders like L’Oréal, Estée Lauder, Shiseido, and Unilever prioritize silicone resins in high-end, broad-spectrum sunscreen and personal care products.

(2) Regulatory Encouragement:

Seen as low-allergenic, stable, and safe, perfect for meeting both local and international cosmetic safety standards and replacing problematic components.

(3) Market Education

More consumers now recognize that “water resistant, sweat-proof, refreshing, and easy to remove” are signatures of high-quality sunscreen, empowered by innovative silicone technology, particularly now as blue light and infrared protection become mainstream problems in personal care.

6. How to enhance the performance of cosmetic products?

As a core functional ingredient in sunscreen, MQ silicone resin is foundational for the cosmetics industry to balance “ultimate protection” with “ultimate skin feel.” Its robust film-forming, water resistance, and gentleness are unmatched, and make for a truly high SPF, broad-spectrum, and superior sun protection experience. Incorporating silicone resins gives products a distinctive, competitive advantage, especially when consumers seek advanced, non-comedogenic, non-toxic, and innovative solutions for their daily personal care.

XJY Silicones is one of China’s leading manufacturers of MQ silicone resins and VMQ silicones, with over 30 years of R&D and manufacturing experience in the silicone industry, and over 15 related patents and technical support. Our silicone raw material products meet the needs of the cosmetics industry, supporting customized solutions for your novel sunscreen product—ready to protect your skin every day against the sun, UV rays, and modern environmental damage. The silicone sunscreen forms a barrier that protects the skin from harmful UV rays, blue light, infrared radiation, and environmental pollutants.