In today’s cosmetics industry, achieving long wear, excellent water resistance, and a smooth skin feel has become essential for developing high-performance cosmetic products. Among the most effective film-forming agents, silicone-based film formers stand out for their ability to create durable, flexible, and breathable films that maintain comfort and beauty. Why choose Silicone Cosmetic Film Former in Modern Cosmetics?

Whether in color cosmetics, sun care, hairstyling products, or skincare formulations, cosmetic film formers play a crucial role in enhancing makeup longevity, improving adhesion, and protecting the skin against moisture loss and environmental stress.

This article provides a detailed overview of cosmetic film-forming agents.

- What are Cosmetic Film Formers?

- What is the mechanism and core properties of film Forming?

- What are Silicone-Based Film Formers and Their Advantages?

- Other Common Film Formers in Cosmetic Formulations

- Film Formers in Modern Cosmetic Formulation Design

- Role of Film Formers in Sunscreen and Hair Care

- How to evaluate film-forming properties and performance?

- Technical Support and Formulation Optimization

- Environmental and Safety Considerations

- How to make your waterproof perform better?

1. What are Cosmetic Film Formers?

A cosmetic film former (also called a film-forming agent) is a polymer, resin, or hybrid ingredient capable of forming a continuous film on the surface of the skin, hair, or nails after application.

These films act as protective layers that provide protection, improve adhesion, and enhance durability and resistance against water, oil, or abrasion.

Popular cosmetic film formers can be classified into two broad categories.

The first includes silicone-based film formers, such as MQ silicone resins and silicone powders, which form a transparent, flexible, and water-resistant film with a pleasant, smooth skin feel. The second group includes acrylic and natural film formers, such as acrylates copolymer, polyvinyl alcohol, and derivatives from castor oil or plant-based polymers. These materials offer alternative textures and film-forming properties, often appealing to natural or eco-conscious brands.

Choosing the right film former for a specific cosmetic formulation depends on the formula type, target performance, and compatibility with cosmetic ingredients and active ingredients that define the final product name and grade.

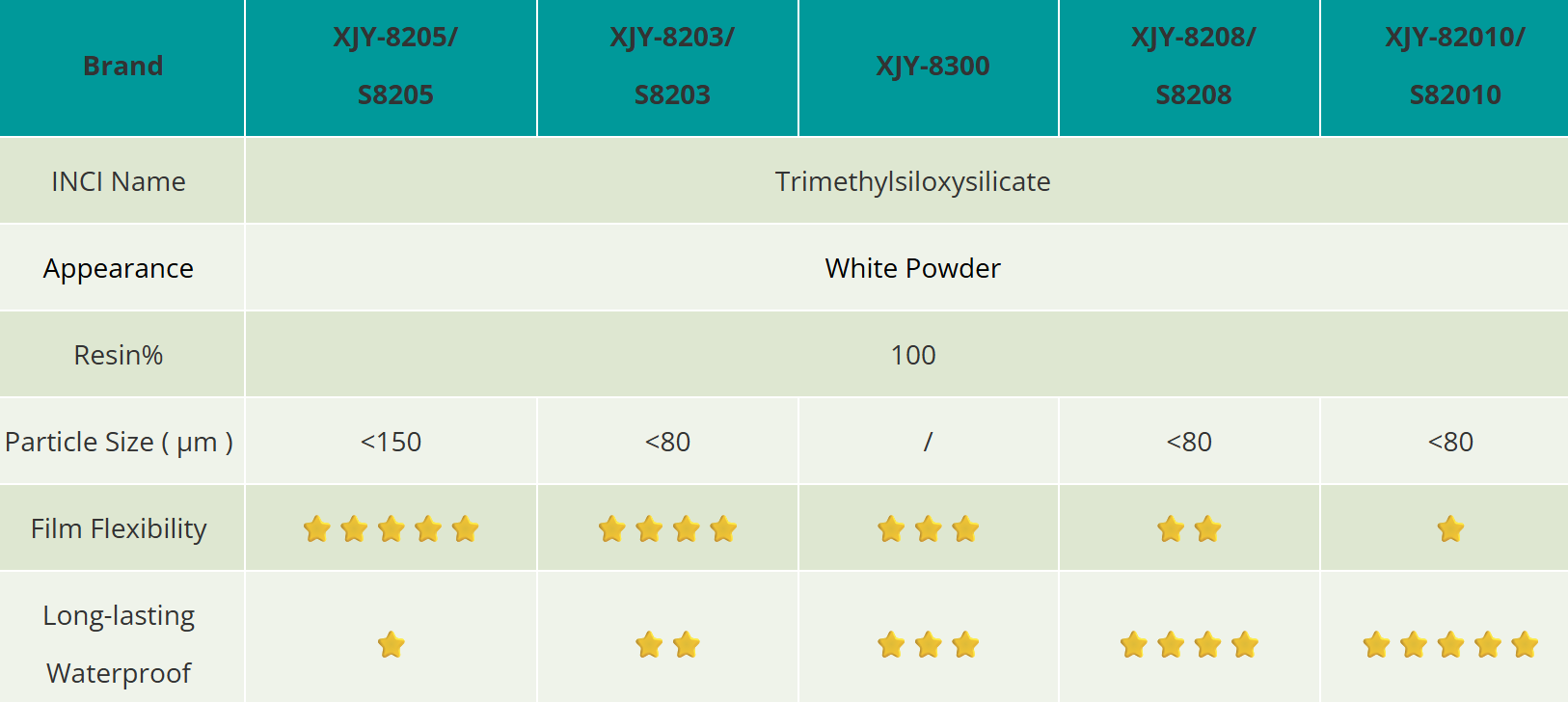

XJY-8203/8205 Methyl MO Silicone Resin

XJY8203/8205 is a solid silicone powder; this silicone can form a continuous layer. The smooth feel it creates provides excellent water resistance and can be used in a variety of skin care formulations. It also has UV protection and can be used in sunscreen products. There are also different organic solvents that can match.

2. What is the mechanism and core properties of film Forming?

When a cosmetic film-forming agent is applied to the skin or hair, it spreads easily because of low surface tension and the help of volatile solvents. As these solvents evaporate, the polymers and resins organize themselves into a continuous, breathable film.

This film on the skin acts as a protective layer, locking in moisture, improving adhesion, and giving a smooth, long-lasting effect.

Good film-forming properties are defined by several important characteristics.

A high-quality film must be flexible enough to move with facial expressions, transparent enough to keep makeup natural, and strong enough to resist washing or rubbing. It should also remain breathable so the skin can maintain normal hydration and comfort throughout wear time.

Properly formulated film formers also contribute to durability, resistance, and smooth appearance — key to decorative cosmetics, foundation, and makeup that lasts all day.

3. What are Silicone-Based Film Formers and Their Advantages?

Among the many types of film-forming agents, silicone-based film formers are especially valued for their combination of film-forming properties, sensory benefits, and formulation flexibility.

Their molecular structure, based on the Si–O–Si backbone, provides outstanding flexibility, heat resistance, and chemical stability.

Meanwhile, methyl side groups on the silicone chains create a hydrophobic surface that delivers excellent water resistance and a smooth skin feel.

Silicone film formers are typically available as low viscosity dispersions, which makes them easy to mix into a wide variety of cosmetic formulations.

When applied, they create a continuous, lightweight, and transparent film that feels silky and non-sticky.

Their breathable yet durable layer protects the skin and keeps active ingredients in place while improving adhesion and durability.

These silicone-based film formers are widely suitable for many personal care products, including foundation, sunscreen products, hairstyling products, and skincare creams.

They help deliver long-lasting results, increase protection, and enhance the beauty and performance of cosmetics across the world.

4. Other Common Film Formers in Cosmetic Formulations

While silicones dominate high-performance formulations, other film-forming agents play vital roles in cosmetics.

Acrylic copolymer emulsions and acrylate copolymer systems are among the most commonly used synthetic materials for creating flexible films.

These polymers form a strong and uniform film that offers excellent water resistance, durability, and adhesion. They are frequently combined with silicone-based film formers to balance hardness and elasticity for desired performance.

Another widely used material is polyvinyl alcohol, a water-soluble polymer that can form transparent and peelable films. It is especially popular in peel-off masks, eyeliners, and nail coatings, where strong adhesion and a clean finish are essential.

As sustainability becomes a top priority, natural film formers such as castor oil derivatives, starch-based resins, and plant polysaccharides have also gained attention.

These natural materials provide mild film-forming capabilities with skin-friendly properties, making them ideal for clean cosmetic formulations and green personal care products.

5. Film Formers in Modern Cosmetic Formulation Design

Incorporating film formers effectively into a formula requires understanding of their compatibility, viscosity, and curing behavior.

When formulating with film-forming agents, formulators must ensure that the polymers and cosmetic ingredients disperse evenly without clumping or separating. The evaporation rate of solvents should be controlled carefully to manage how quickly the film forms on the skin surface.

A foundation formulation, for example, may combine silicone-based film formers with acrylate copolymer emulsions. The silicone resin contributes flexibility and a soft touch, while the acrylic copolymer improves adhesion and structure.

Adding castor oil or other emollients improves spreadability and maintains skin hydration, while volatile solvents help form a smooth, even film during application.

The final result is a long-lasting, water-resistant, and smooth makeup finish that preserves comfort and moisture balance on the skin.

6. Role of Film Formers in Sunscreen and Hair Care

In sun care formulations, film-forming agents are indispensable.

A breathable film helps keep UV filters evenly distributed across the skin, increasing protection and ensuring consistent SPF values.

By using silicone-based film formers or acrylic copolymer emulsions, formulators can achieve excellent water resistance, so sunscreen products maintain performance even after swimming, sweating, or prolonged wear.

In hairstyling products, film formers create a flexible coating that enhances hold, gloss, and humidity resistance.

Polymers derived from acrylic acid, combined with silicone resins, coat each hair strand with a lightweight film that keeps hairstyles in shape without stiffness.

This ensures long wear and consistent performance under different environmental conditions, while maintaining a natural and smooth look.

7. How to evaluate film-forming properties and performance?

The performance of film-forming agents in cosmetics is assessed by evaluating film continuity, adhesion, water resistance, and durability.

A well-designed film should be uniform and defect-free, forming a continuous film that adheres strongly to the surface of the skin or hair.

Good adhesion ensures that pigments or active ingredients stay in place for extended wear time, while excellent water resistance guarantees that the film remains intact after exposure to water or sweat.

Durability and long wear performance are verified through rub tests and extended wear time evaluations, where film integrity is monitored after multiple hours.

In addition, the breathable film should preserve skin hydration and comfort without occlusion.

These combined properties define the desired performance for decorative cosmetics, sun care, and skincare formulations that must look beautiful and feel pleasant throughout the day.

8. Technical Support and Formulation Optimization

Formulating with film-forming agents often requires professional technical support from ingredient suppliers.

Compatibility testing, viscosity adjustment, and evaluation of low viscosity grades are crucial for achieving consistent quality.

When introducing a new product name or grade, formulators should confirm solvent stability, dispersion quality, and performance reproducibility.

To optimize formulation results, it’s often effective to combine silicone-based film formers with acrylic copolymer emulsions.

This hybrid system provides both flexibility and excellent water resistance, balancing hardness and softness within the final film.

Using natural film formers alongside synthetic ones can also deliver suitable performance for clean beauty trends.

Careful selection of polymers and resins ensures that each formula achieves its intended characteristics, from soft matte foundations to glossy hair or nail coatings.

9. Environmental and Safety Considerations

Modern cosmetic film-forming agents are being formulated to meet strict environmental and safety requirements.

Manufacturers aim for eco-friendly, low-VOC, and fluorine-free solutions by using renewable resources such as castor oil, biodegradable polymers, and sustainable solvents.

At the same time, attention is paid to skin safety, ensuring that film formers do not interfere with skin hydration or cause irritation.

Proper handling and storage protect both product performance and environmental safety, guaranteeing that each cosmetic film remains stable and effective.

10. How to make your cosmetics perform better?

From decorative cosmetics to sun care, hairstyling products, and skincare, film-forming agents remain among the most crucial cosmetic ingredients in the world.

They help create durable, long-lasting, and smooth finishes while maintaining moisture, beauty, and protection. Both silicone-based film formers and acrylic copolymer emulsions provide outstanding film-forming properties, allowing formulators to design personal care products that perform flawlessly.

Whether using synthetic polymers, natural film formers, or hybrid systems, these ingredients enable cosmetic formulations to achieve a balance between durability, comfort, and environmental responsibility.

Through continuous research and technical support, formulators can continue developing cosmetics that not only deliver desired performance but also enhance the skin’s natural beauty with a comfortable, flexible, and breathable film that lasts. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone cosmetics field and support the provision of diversified customized solutions.