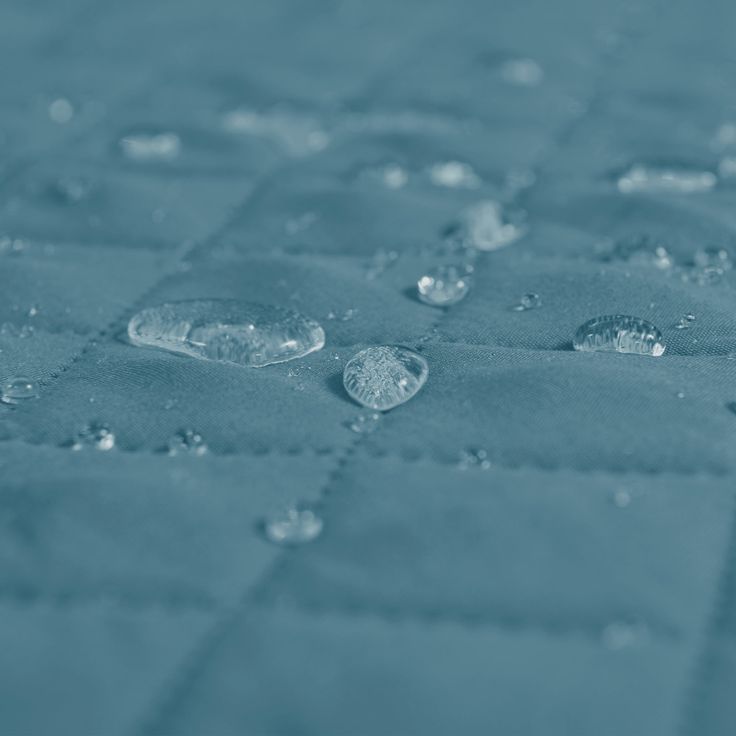

Waterproof textiles have become an indispensable part of modern life, from outdoor sportswear to high-performance workwear, home furnishings, and even technical industrial fabrics. Among the various waterproofing technologies available today, silicone textile solutions—particularly those utilizing silicone resin as a core component—stand out for their superior effectiveness, durability, and eco-friendliness. In this article, we dive into the cutting-edge world of silicone resin fabric waterproofing agents, the advantages of silicone resin waterproof finishes for fabrics, and why silicone resin breathable waterproof fabrics are the future of functional textiles.

There are six aspects to introducing silicone material:

Why is Silicone Resin Fabric Waterproofing Agent The Game Changer?

How is Breathability Achieved?

How to make Silicone Textile better?

1. What is a Silicone Textile?

A silicone textile refers broadly to any fabric surface or composite that is treated or coated with silicone-based agents to impart special functionalities—most notably, water repellency, stain resistance, improved flex life, and sometimes even extra softness or breathability. Silicone itself is an inert, biocompatible polymer with outstanding thermal and chemical stability, making it ideal for textile protection and enhancing physical properties.

Silicone textiles can be produced through several methods:

Coating: Applying a thin film or layer of silicone resin directly onto the fabric, which can increase the fabric's durability and resistance to moisture.

Finishing: Using silicone-based dispersions as part of the textile finishing process.

Impregnation: Penetrating the fibers with a silicone resin solution.

Regardless of the method, the resulting silicone textile demonstrates enhanced performance and physical properties suitable for demanding environments, such as personal protective equipment and cotton fabrics with improved durable abrasion resistance.

XJY-711 Hydrogen Terminated Methylhydrogensiloxane/Dimethylsiloxane Copolymer

It can be used as a waterproofing agent for adhered fabrics.

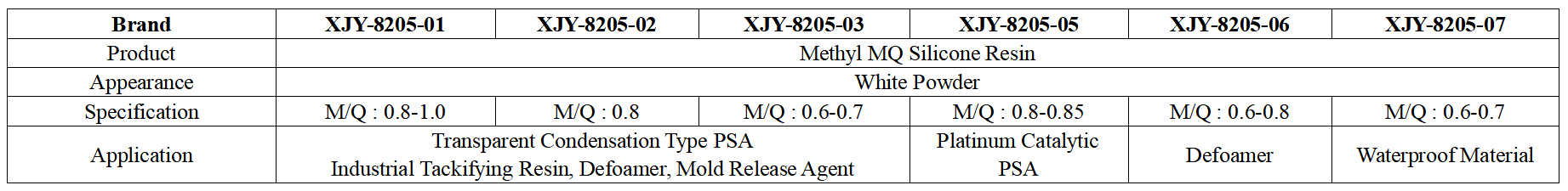

XJY-8205 Methyl MQ Silicone Resin

It is a solid powder resin with excellent water repellency, forming a durable film that will not shrink and can be used as a water repellent to adjust viscosity.

2. Why is Silicone Resin Fabric Waterproofing Agent The Game Changer?

Traditional waterproofing agents for fabrics often include waxes, fluorocarbons, or polyurethane-based polymers, but these may compromise breathability, softness, or raise environmental concerns. Enter silicone resin fabric waterproofing agent—an advanced solution that leverages the unique molecular characteristics of silicone resin, such as low surface tension, temperature resistance, and excellent performance under various conditions.

Compared to other agents, silicone textiles retain natural texture and elastic feel, making them ideal for comfort-focused applications.

3. How Does silicone fabric Work?

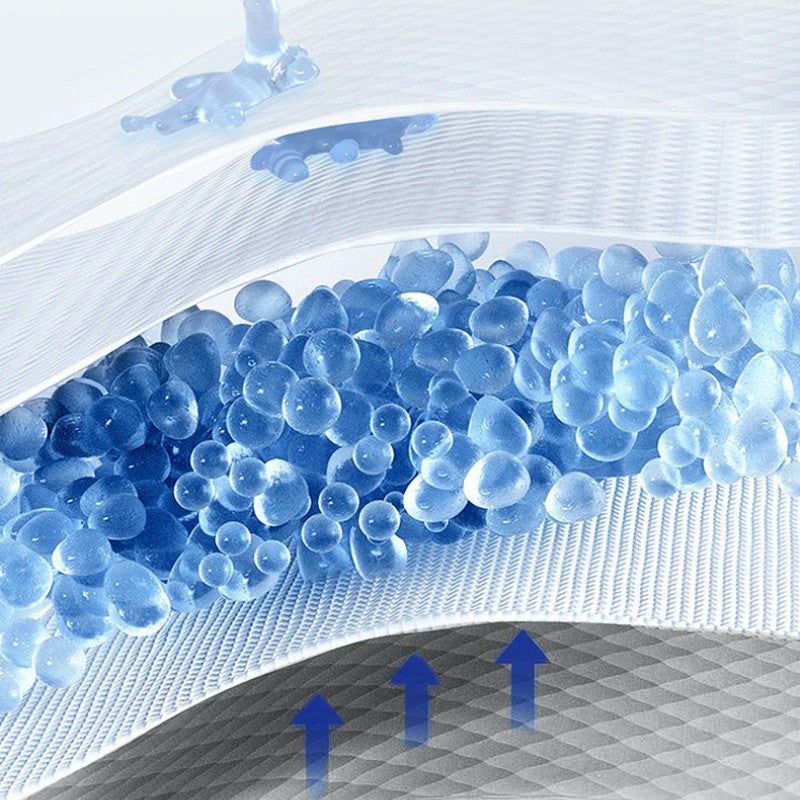

Silicone resin forms a microscopic protective layer over the fiber surface, preventing water molecules from penetrating and absorbed while retaining the fabric's natural feel and breathability. Unlike wax-based coatings, silicone resin fabric waterproofing agents anchor themselves onto the textile with strong chemical bonds, resulting in:

- Long-lasting water repellency

- Resistance to repeated laundering and abrasion

- Minimal impact on fabric weight, texture, or softness

Applications

Outdoor apparel: Jackets, pants, tents, sleeping bags (example: sports jackets with a flexible silicone middle layer for increased comfort and thermal insulation)

- Sporting gear: Running wear, swimwear, hiking boots

- Home textiles: Sofa covers, cushions, curtains (wet and dry protection)

- Industrial: Air filters, conveyor belts, protective uniforms, and personal protective equipment for safer work environments

Silicone resin finishes are also commonly found in medical textiles for healthier hospitals, where disinfecting with solutions such as hydrogen peroxide cleaner disinfectant, Clorox, and Lysol is critical, due to their chemical resistance and ease of cleaning.

Environmental Benefits

Many silicone resin waterproofing agents are fluorine-free, reducing ecological impact and meeting strict global regulations (applicable with limits on emissions and hazardous substances). They have developed into cost-effective solutions for manufacturers, as well as posing lower toxicity risks compared to older chemical systems.

Silicone Resin Waterproof Finish for Fabrics:

Superior Protection, Lasting Performance

The term silicone resin waterproof finish for fabrics describes the protective treatment applied to textiles to impart both water repellency and durability. Silicone resin finishes are developed to solve common issues faced by traditional waterproofing:

Wash Durability:

While waxes and silicones may initially resist water, they often wash out after a few laundry cycles; silicone resin finishes can last through dozens of washes, showing high tensile and abrasion resistance.

Some waterproof agents make fabrics stiff and uncomfortable. Silicone resin finishes maintain—sometimes even improve—the softness of the original material and keep elastic qualities.

Chemical Resistance:

Silicone resin finishes resist acids, bases, and common household chemicals and solvents.

4. How to finish silicone fabric?

Silicone resin waterproof finishes can be applied in several textile finishing stages (process):

Padding or dipping methods (most manufacturers use continuous or batch methods)

Spray application (helpful for large-width rolls)

Batch or continuous finishing

Once cured, the finish forms a network of hydrophobic molecules on the surface and within the fibers, offering both surface water repellency and deep protection. Silicones' high temperature resistance and chemical stability make them ideal for use on fabric exposed to the elements or frequent laundering.

Case Study: Outdoor Jackets

Outdoor apparel brands are increasingly switching to silicone resin waterproof finishes for jackets and raincoats. Compared to older technologies, silicone resin-treated fabrics maintain their performance in harsh conditions, dry quickly, and offer breathability—key for active use. The increase in market preference for such finishes is also driven by their energy-efficient curing process during manufacturing.

Silicone Resin Breathable Waterproof Fabric: Comfort Meets Functionality

One persistent myth about waterproofing is that “waterproof means unbreathable." Silicone resin technology puts this myth to rest with the silicone resin breathable waterproof fabric innovation.

5. How is Breathability Achieved in silicone fabric?

Silicone resin coatings can be engineered to block water droplets (which are larger) but permit vapor molecules (which are smaller) to pass through. The result: no wetting from rain or spills, but still comfort from sweat and body heat escape. This is achieved partially due to low surface tension and the unique form of silicone elastomers that fill the gaps on a micro level, improving breathability while maintaining protection.

It is clear from industry data and user experience that silicone resin leads the pack, especially in the high-value class of functional fabric segments.

Choosing a Silicone Resin Solution: Factors to Consider

When selecting a silicone resin fabric waterproofing agent, waterproof finish, or seeking to produce breathable waterproof fabrics, consider:

Fabric Type: Cotton fabrics, polyester, nylon, blends, and multi-layer composed textiles

End Application: Fashion, industrial, outdoor, medical, sports, or personal protective equipment

Required Durability: Wash cycles, abrasion, tensile resistance, and overall durable physical properties

Environmental Regulations: Compliance with REACH, OEKO-TEX, ZDHC, limits, and safety standards

Supplier Quality: Technical support, customization, and quality consistency in every sample batch provided

For professional textile manufacturers, partnering with an experienced silicone resin specialist is key to achieving reliable, marketable, and eco-conscious waterproof fabrics.

6. How to make Silicone Textile better?

The advancement of silicone resin technology has revolutionized waterproof textiles. Whether you are producing the next generation of outdoor adventure gear, creating comfortable home furnishings, or seeking eco-friendly industrial fabrics, silicone textile solutions provide the performance, durability, and comfort consumers expect. The presence of advanced finishing options allows for innovative modification of traditional textiles.

From silicone resin fabric waterproofing agents to silicone resin waterproof finishes for fabrics and the innovative silicone resin breathable waterproof fabrics, the versatility of silicone is unmatched. For businesses eager to stay ahead in textile innovation, investing in silicone resin-based treatments is the definitive strategy for sustainable and market-leading products. How can product competitiveness be enhanced?