Leather processing plants to make leather products process, often need three stages: preparation stage, tanning stage, and finishing stage. But in the leather products processing process, if the operation is not appropriate, it is easy to cause foam problems, we need to use a leather antifoam agent to solve, it generally uses silicone antifoam agent, why use silicone defoamer for leather?

Silicone-based defoamers are a class of surfactants, mainly composed of siloxane compounds. Compared with other surfactants (mineral oil), silicone defoamer has the following characteristics: excellent defoaming effect, even at very low dosages can also be effective in eliminating and inhibiting foam; easy to use, high-temperature resistance, high temperature, high pressure, strong acid, strong alkali environment performance; environmental protection and reliable, it will not cause pollution to the environment.

There are seven aspects to introducing silicone defoamer for leather:

- What are the reasons for leather blistering?

- What is the problem of leather blistering?

- Why apply silicone defoamer?

- What are the properties of silicone defoamers?

- What are the advantages of silicone defoamer?

- What should I pay attention to when using silicone defoamer?

- How to make silicone defoamer performance better?

1. What are the reasons for leather blistering?

(1) In the leather production process, due to the leather has some of the use of cowhide, sheepskin, crocodile skin, etc., these skins belong to the natural skin, in some of the mixed materials with, sometimes with some of the materials in which a chemical reaction occurs, producing carbon dioxide gas, which caused by blistering.

(2) In the leather production process, due to the operation is not standard, air into the leather inside, resulting in the surface raised blistering.

(3) If in high-temperature sunscreen conditions, leather products are easy to cause surface delamination relaxation, at this time some small microporous will also enter the leather inside, making the leather blister.

(4) Leather will cause leather internal oil loss in water, triggering the original fiber structure changes, so that the foam problem.

2. What is the problem of leather blistering?

If the leather foaming problem is not solved, it will affect the beauty and durability of leather products, as well as lead to the production of leather products not sold out. So we can use leather defoamer to solve.

3. Why apply silicone defoamer?

(1) Silicone defoamer can be well soluble with leather, with effective foam inhibition and defoaming effect, compared with the case of a leather defoamer not used, the use of leather defoamer can be more to maintain the durability of the product, in the high-temperature sun exposure conditions, it is not easy to blister. In addition, in the process of processing, it can also be a good solution to the operating error of the foam problem.

(2) Leather manufacturers use a variety of products in their surface treatment process, including specific silicone enhancers, in order to make their leather obtain the right performance, such as softness, water absorption or waterproof, resistance to yellowing, skin friendliness, and beautiful appearance.

(3) In leather chemical processing, tanneries, leather product manufacturers and shoemakers also use silicones in their manufacturing processes to enhance the appearance, feel, water resistance, and durability of their products, many of which also generate unwanted foams at various stages of processing.

(4) Silicone foam control products and processing aids for the leather manufacturing industry, when used in the right combination, allow for more efficient and cleaner production, improve the quality of the final product, reduce waste and energy consumption, and promote recycling. They are safe for personnel and equipment and comply with the most stringent national and international standards.

4. What are the properties of silicone defoamers?

Silicone foam control solutions (also known as anti-foams or defoamers) are considered the material of choice for the textile and leather industries because they offer several advantages:

(1) They prevent the creation of unwanted foam and eliminate it faster and more efficiently when it occurs, which is known as the knockdown effect, allowing for faster processing and improved leather productivity and quality.

(2) They reduce the consumption of water and chemicals such as bleach or dyes.

(3) They have a higher resistance to chemical additives as well as to temperature changes, thus ensuring stability throughout the production process.

(4) The amount of silicone product required to achieve the desired effect is much lower than with organic or mineral-based products and has a longer-lasting low surface tension, which is especially important in complex and long-lasting processes.

(5) Silicones are inert and therefore safer for people and the environment.

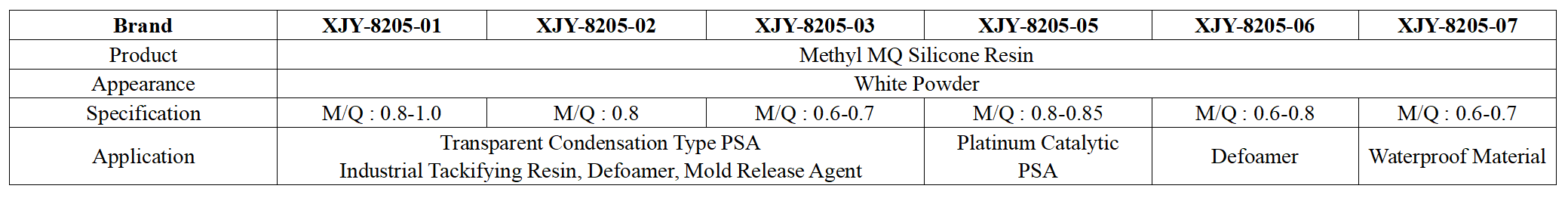

XJY-8205 Powdered Methyl MQ Silicone Resin is a solid food-grade powdered reactive silicone resin. The resin has excellent transfer resistance and water resistance, forming a long-lasting film, which is one of the raw materials of silicone emulsion antifoam agents in aqueous systems and can be used in food processing, coatings, oil extraction, and other fields.

5. What are the advantages of silicone defoamer?

(1) Good defoaming and foam inhibition performance

Silicone antifoam agents can not only quickly eliminate the foam that has been generated, but also effectively inhibit the generation of foam, so organic silicon antifoam agent has good antifoam and foam inhibition performance.

(2) Wide range of applications

Silicone oil is the main raw material of silicone antifoam agents, it has a special chemical structure, does not dissolve with water or polar group-containing substances, and does not dissolve with organic substances containing hydrocarbon groups. Since silicone oil is insoluble in many substances, silicone antifoam agents can be applied to both aqueous systems and can be used in oily systems for defoaming, the scope of application is quite wide.

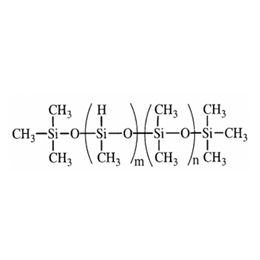

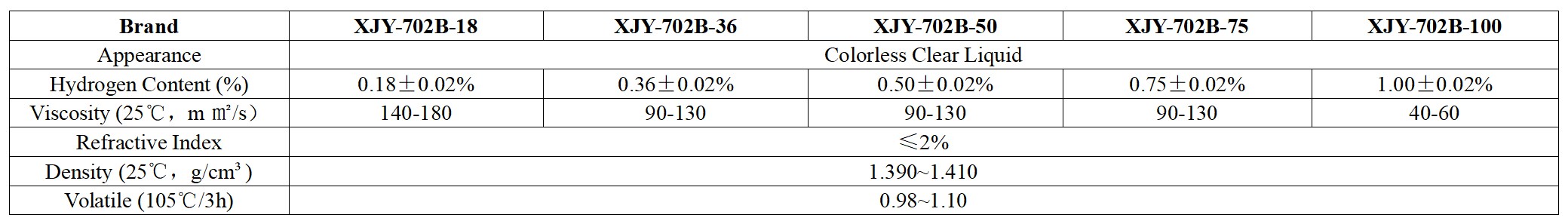

XJY-702 Methylhydrosiloxane / Dimethylsiloxane copolymer is non-toxic and tasteless, with active groups, in the catalyst and the role of the double bond, hydroxyl, and other groups can be reacted in the petroleum industry, metalworking fluids, pulp and paper industry, coatings, and other industries in the silicone antifoam agent and other products such as the basic raw materials.

(3) Good chemical stability

From a chemical point of view, due to the Si-O bond being relatively stable, the chemical stability of silicone oil is certainly very high, and it is difficult to have chemical reactions with other substances. Therefore, in the production of silicone antifoam agents, as long as through reasonable preparation, the production of silicone antifoam agents can be well in the acid and alkali salt systems.

(4) Low surface tension

The surface tension of silicone oil is usually 20-21 dynes/cm, while the surface tension of water is usually 72 dynes/cm, so its surface tension is lower than that of general foaming liquid, which makes the antifoaming effect better.

(5) Low dosage

Silicone antifoam agent also has a significant advantage, is they use very little, only need to add a millionth of the weight of the medium, can produce the effect of defoaming, and are used at low cost.

6. What should I pay attention to when using silicone defoamer?

(1) Defoamer is divided into industries, there is no universal defoamer. So we have to choose the most suitable silicone defoamer for our own industry.

(2) In the choice of antifoam agent, pay attention to the choice of the production system that can eliminate the harmful foam but can not produce a bad effect on the production system in the material, this is everyone in the purchase of the time need to consider clearly.

(3) The defoamer used in industry and the defoamer used in food and medicine are different, the defoamer used in food and medicine needs to have the certificate recognized by the state, while the industrial grade does not have such strict requirements.

(4) defoamer is divided into water-based defoamer and oil-based defoamer, in the choice of which defoamer needs to distinguish their own production system is suitable for which kind of defoamer.

(5) Once the type of silicone defoamer is determined, you can choose a stable product quality in this type of defoamer, so as not to cause production problems due to product problems and thus cause serious losses.

(6) Silicone antifoam agent manufacturers, the mixed, antifoam agent market is relatively chaotic and must be tried before making a decision.

(7) Silicone defoamer is not necessarily expensive and must be the best, but often cheap indeed, and must not be too good. The so-called penny-wise and pound-foolish, product is the need for cost and profit. Too cheap products, content, and effects will inevitably be greatly reduced.

(8) Distinguish their own industry production process, there is high temperature, strong acidity, strong alkaline, or high shear and other environments, because these may destroy the defoamer to affect the defoaming effect if there are the above problems need to choose a special antifoam agent, so the price will be relatively high.

7. How to make silicone defoamer performance better?

Silicone defoamer has the advantages of high-efficiency defoaming, lasting foam inhibition, very low surface tension, strong versatility, environmental protection, and safety, ease of use, etc. It is suitable for a variety of different scenes and systems. It can be used without fear of adverse effects on the environment and human body during the use process for frequent emptying foam. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material full-line products can meet the needs of the defoamer field and support the provision of diversified customized solutions.