A hot air balloon is a device that utilizes the principle of static buoyancy to lift off into the air: because the hot air in the airbag is lighter than the air outside. For safety reasons, airbags are required to have special properties and life expectancy, so silicone is introduced as a surface coating material, why choose silicone for fabric coatings?

After the use of coating finishing to textile finishing, silicone coating has received wide attention in functional fabrics due to its unique properties. Silicone fabric coating agent is uniformly coated on the fabric surface and can form polymer film. After fabrics are finished with a coating agent, they can obtain a unique style, feel, and durable appearance as well as a variety of special functions, such as good water repellency and water permeability, flame resistance, high tear strength, insulation, etc., which can greatly enhance product life and added value.

The following six aspects of silicone in the introduction of functional fabric coatings:

- Why use silicone fabric coating?

- What is silicone coating?

- What is the mechanism of the silicone coating agent?

- What are the features of silicone-coated fabrics?

- What are the applications of silicone fabric coating?

- How to make silicone coating performance better?

1. Why use silicone fabric coating?

Changes in hot air ballooning over the last few hundred years have mainly involved the materials used for the airbags. Most airbags are made of coated ripstop nylon fabrics. Once the flamethrower is ignited, the internal circulating temperature of the balloon is usually around 120°C, while the external temperature is usually close to 20°C. This temperature difference of almost 100°C requires the balloon's airbag material to have excellent temperature resistance. When the balloon is ready to take off the hot air will be concentrated in the upper part, where the airbag must withstand a greater thermal load -- and this is exactly where silicone coatings come in. Currently, people are increasingly choosing silicone rubber as a hot air balloon airbag coating material, a thin-thickness silicone coating can satisfy the requirements.

2. What is silicone coating?

Silicone rubber is a rubber elastomer based on siloxane, which is produced through a cross-linking reaction. Silicone macromolecules constitute a polymer chain in the cross-linking process that will form a three-dimensional mesh structure, it is extremely resistant to high temperatures, but at the same time has low-temperature flexibility, chemical stability, and biocompatibility. It can be used as glue, adhesive, or coating material.

When used as a coating material, silicone rubber provides long-lasting protection for sensitive substrates (such as plastic) from surrounding environments such as high temperatures. This is because silicone coatings impede heat transfer between the substrate and the surrounding environment, mitigating the effects of thermal stress on the substrate. Silicone rubber can be continuously exposed to oxygen, ozone, or UV radiation, and absorbs UV-C radiation and some UV-B radiation.

Not only silicone rubber, but also silicone oils and other silicone fluids can be used for fabric coatings, and a small amount of silicone coating can be applied to the surface to enhance its performance and functionality. Silicone coatings can provide fabric surfaces with properties such as water repellency, oil repellency, flame retardancy, abrasion resistance, and chemical resistance.

According to the different product applications and silicone rubber performance form, viscosity, and so on, the Silicone fabric coat processing method is also different. At present, the silicone fabric coating process is mainly divided into knife coating, dip coating, screen printing, and extrusion, it can be used in rubber gloves and other applications. During processing, depending on the viscosity of the liquid silicone, it can be considered whether it is necessary to add solvents to adjust the viscosity of the product and reduce foam.

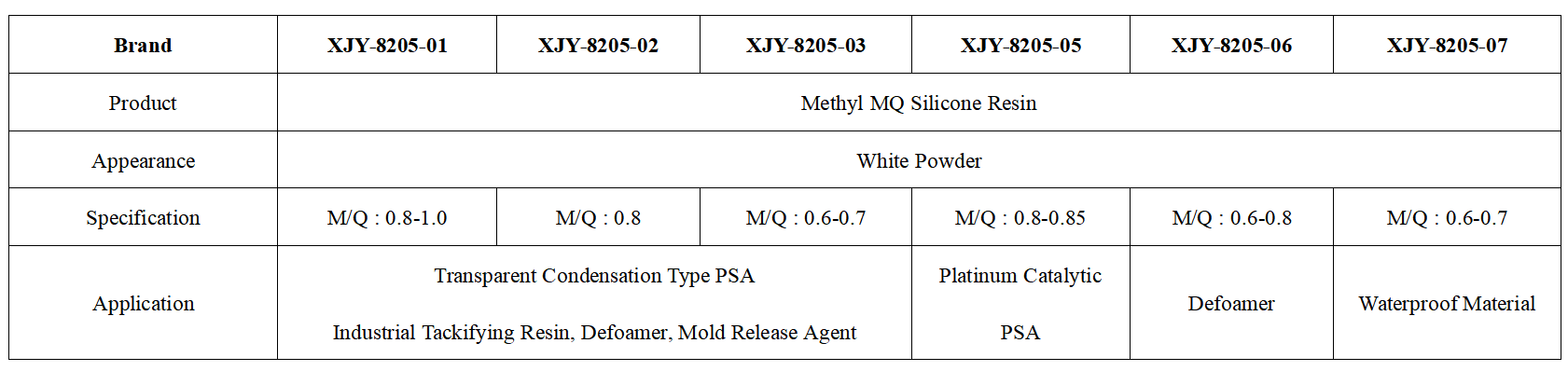

XJY-8205 MQ Silicone Resin Powder

It is the co-hydrolysis product of tetraalkoxysilane (Q unit) and trimethyl alkoxysilane (M unit), which can be used as reinforcing material to prepare condensed liquid silicone rubber (LSR).

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Polydimethylsiloxane

It is a colorless and transparent liquid resin, consisting of vinyl MQ silicone resin and vinyl silicone oil, it can be used for LSR liquid bonded silicone rubber, but also can be used for other two-component additive adhesives.

3. What is the mechanism of the silicone coating agent?

The Polysiloxane coating agent is mainly composed of Polysiloxane elastomer with active groups in the metal salt or organic compound under the action of the acid, which can be a cross-linked reaction.

Different Polysiloxane elastomers and different catalysts can make the coated textiles have different properties and styles, such as waterproof or antistatic. Selected polysiloxane coating agents and Polyurethane coating agents mixed in a certain proportion and coated on the textile, get satisfactory waterproof and moisture permeability effects. Its mechanism is that the waterproof depends on the continuous film of coating and the water repellency of polysiloxane, while the moisture permeability relies on the good air permeability of Polysiloxane and the Hydrophilic groups in the Polyurethane molecule of the “chemical ladder stone” effect, through adsorption, diffusion, desorption mode of moisture transfer.

XJY-701 Polymethylhydrosiloxane

It is a colorless free-flowing liquid, which can be used as a waterproofing agent for fabrics, glass, ceramics, paper, leather, metal, cement, marble, and other materials, especially cloth. Under the reaction of the metal catalyst, Polymethylhydrosiloxane can be crosslinked at low temperatures into a waterproof membrane on the surface of various materials.

4. What are the features of silicone-coated fabrics?

Silicone resin coating usually refers to the formulation of silicone resin based on the copolymerization of dichlorosilane and trichlorosilane. Fabrics are fabrics that have a silicone coating applied to the surface to enhance their performance and functionality. The silicone coating provides the fabric surface with properties such as water repellency, oil repellency, flame retardancy, abrasion resistance, and chemical resistance.

(1) Silicone-coated fabrics with excellent weather resistance in -50 ℃ conditions still have good impact strength and flexibility, the use of Polyester modified, can be used at low temperatures -80 ℃.

(2) Silicone-coated fabrics have outstanding insulation in high temperature and humidity conditions with good electrical insulation, up to class H, and a breakdown voltage of 60-100 kV/mm.

(3) The chemical resistance of silicone-coated fabrics is strong at 100 ℃, 3 % lye immersion for 100 h, or 5 % salt water immersion for 70 h without change. However, the resistance to dilute hydrochloric acid, and dilute sulfuric acid corrosion performance is not good, as well as oil resistance is not strong, can be used as a lubricant, and will become soft in the event of gasoline.

(4) Silicone-coated fabrics have high mold resistance, silicone-coated fabrics do not contain oil components, and mold can not survive.

(5) The curing temperature of silicone-coated fabrics is high, most silicone-coated fabrics need high-temperature baking.

(6) Silicone-coated fabrics are poorly resistant to organic solvents.

(7) Pure silicone-coated fabrics have low viscosity, and pigments made of magnetic paint are easy to precipitate.

5. What are the applications of silicone fabric coating?

Withstood the rigors of the hot air balloon, with its many excellent performances, silicone rubber in other fabric coating fields also has a wide range of applications. Silicone rubber can be applied to fabric coatings in various industries such as automotive, medical, power and energy, construction, industrial and civil:

(1) The heat-resistant, breathable, and long service life of silicone rubber is suitable for adiabatic protection of fabric coatings.

(2) The low-temperature flexibility and thermal insulation of silicone rubber make it suitable for outdoor equipment fabrics.

(3) Silicone rubber is skin-friendly and has soft performance, which is suitable for direct contact with the skin of the fabric.

(4) Silicone rubber has excellent breathability and anti-ultraviolet aging performance, which is suitable for parachutes, light curtains, and automotive airbags.

(5) In addition, silicone rubber has excellent safety and biocompatibility, which is suitable for food and drug delivery.

6. How to make silicone coating performance better?

After finishing with a silicone coating agent, you can get a unique style, feel, and appearance as well as a variety of special features, that can greatly enhance the added value of the product. At present, the world's coating finishing textiles account for 30% of the total amount of textiles, and coating agent consumption in terms of quality has reached about 50% of the total amount of textile auxiliaries. How to improve the competitiveness of your products? Specify weight requirements please contact us.

XJY Silicones is one of the leading manufacturers of silicone MQ resins and VMQ silicones in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone products can meet the needs of the textile field and support the provision of diversified customized solutions.