With the acceleration of global industrialization and the rise in urbanization levels, waste treatment has become a critical component in addressing sustainable development and environmental protection for countries worldwide. One advantage of silicone defoamers is their ability to help control these costs by efficiently preventing and eliminating foam. How effective are silicone-based defoamers in the wastewater treatment industry?

Over the past decade, silicone defoamers have gained prominence in the water treatment industry due to their superior performance, excellent environmental compatibility, dual defoaming and foam control (anti-foaming) effects, and adaptability to various aqueous systems in industrial processes. Silicone defoamers are now widely used across the wastewater treatment sector due to their proven effectiveness. They have become an essential foundational material in many applications and various wastewater treatment systems.

There are seven aspects to introducing silicone defoamer:

- What are the hazards of foam?

- What is the basic function of a defoamer?

- What is the composition and mechanism of silicone defoamers?

- What are the advantages of silicone defoamers?

- How are silicone resin defoamers applied in wastewater treatment?

- What is the market trend for silicone defoamers?

- How to enhance the advantages of silicone defoamers?

1. What are the hazards of foam?

In wastewater treatment processes such as aeration, biological treatment, activated sludge, sedimentation, and filtration, factors such as surfactants, microbial metabolic products, and flocculant residues can easily lead to the formation of large amounts of persistent foam, primarily causing the following hazards:

Impact on equipment operation: Foam can block aeration ports, overflow channels, and collection tanks such as the recovery tank, reducing the effective volume of equipment and leading to reduced production capacity. Additionally, foam can cause defects in surface coatings and interfere with process quality, making it essential to control foam formation.

Reduced treatment efficiency: Foam floating and forming a covering layer impedes gas-liquid exchange, which can decrease both operational efficiency and product quality by lowering oxygen dissolution rates and thereby affecting microbial pollutant removal efficiency.

Increased chemical consumption: Foam carries away organic compounds and pollutants, leading to increased chemical (detergents, additives) usage and higher costs.

Environmental pollution: Overflowing biochemical foam can cause secondary pollution and even impact downstream environmental safety and pools.

Maintenance burden: Frequent foam removal increases labor maintenance and equipment downtime.

2. What is the basic function of a defoamer?

The role of a defoamer is to rapidly eliminate or suppress foam formation, ensuring the stable, continuous, and efficient operation of waste treatment. Antifoaming agents can be classified into mineral oil-based, alkyl alcohol-based, polyether-based, and silicone-based defoamers according to their materials and composition. Among these, silicone antifoam products, due to their unique silicone chemistry and excellent comprehensive performance, are gradually replacing traditional defoaming products and have become the industry’s preferred control choice in the first place. Silicone-based defoamers have the positive effect of efficiently reducing foam and stabilizing wastewater treatment processes, leading to improved process efficiency and product quality.

3. What is the composition and mechanism of silicone defoamers?

Silicone defoamers typically use polydimethylsiloxane (PDMS) and other siloxane-based polymers as core raw materials, combined with emulsifiers, carriers, solvents (oils), etc., to form various formulations such as silicone emulsions, oil dispersions, or powders. These versatile formulations allow silicone defoamers to be used in a wide range of wastewater treatment applications. Their core consists of a Si-O-Si chain-like skeleton, with hydrophobic organic groups such as methyl groups decorating the outer side, resulting in extremely low surface tension and highly hydrophobic and “anti-foaming” capabilities.

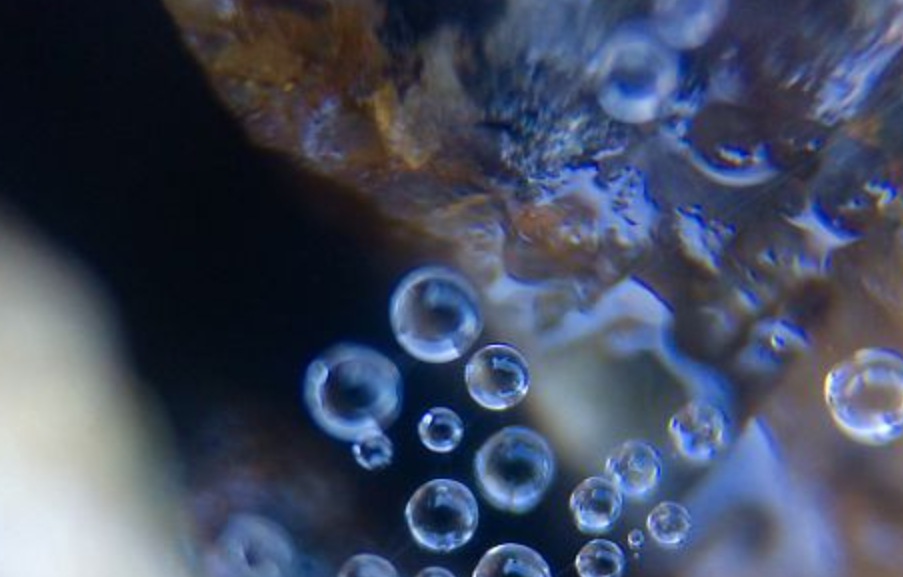

During wastewater treatment, organosilicon defoamers are dispersed as microscopic particles on the foam surface and interfaces, acting on the foam through the following mechanisms:

Reducing local surface tension to rapidly “break down” the foam membrane, causing the bubbles and foam to quickly drain and collapse.

Adsorption at the gas-liquid interface weakens the elasticity of the liquid membrane, making the foam prone to rupture and improving foam control.

Forming a hydrophobic layer within the system to prevent the formation of new foam, achieving long-term antifoaming agent action and suppression.

XJY-6010/XJY-6011 /XJY-6012 methyl MQ silicone resin for defoamer

It is a solid powdered resin. This resin can provide good defoaming, hydrophobic, and waterproof properties.

4. What are the advantages of silicone defoamers?

(1) Rapid defoaming action and long-lasting effectiveness

Due to the extremely low surface tension of silicone molecules, they can quickly “penetrate” the foam membrane surfaces within seconds, achieving instant defoaming. Additionally, the hydrophobic barrier layer formed can maintain defoaming effects for an extended period, reducing the frequency of reapplication in many industrial processes.

(2) Strong adaptability and resistance to high temperatures and acids/alkalis

Silicone antifoam remains active regardless of pH changes or salt concentration, maintaining stability across a wide pH range (0–14) and high-temperature environments (up to ~150°C). They are suitable and compatible with all mainstream wastewater treatment processes (municipal, industrial, chemical, dyeing, pulp, electroplating, etc.) for both aqueous systems and non-aqueous systems.

(3) Excellent dispersibility, low concentrations

Silicone defoamers require only extremely low concentrations (typically 20–200 ppm) to achieve superior defoaming and antifoaming effects. Their strong dispersibility allows them to rapidly distribute throughout the system, maximizing efficacy and improving overall performance.

(4) Non-toxic and environmentally friendly

High-purity organic silicone materials are inherently biocompatible, non-toxic, and odorless, do not produce harmful byproducts, and do not pollute water bodies or downstream environments. They comply with stringent environmental regulations, and certain products are available in food grade for applications such as carpet extractors and indirect food contact.

(5) No adverse effects on subsequent treatment processes

Compared to traditional mineral oil-based or certain emulsion-based defoamers, silicone defoamers do not cause oil sludge suspension or equipment blockages, nor do they impair the treatment effectiveness of subsequent flocculation, sedimentation, or filtration processes. This makes them suitable for many applications and medium types in wastewater treatment.

(6) Diverse product formulations and strong process compatibility

Can be formulated into various types such as silicone emulsion, oil, or foam powder according to process requirements, compatible with automatic dosing, manual addition, or online continuous treatment methods. This flexibility ensures sufficient process adaptation in different industrial processes.

5. How are silicone resin defoamers applied in wastewater treatment?

(1) Municipal wastewater treatment plants

Municipal domestic wastewater contains large amounts of surfactant sludge, proteins, and fats, which easily lead to excessive surface foam formation in aeration and biological treatment tanks. Using silicone defoamer can quickly eliminate surface foam, stabilize aeration and secondary settling tank operations, and improve effluent water quality and plant capacity. It is particularly effective for foam control during high-load operations, high-temperature seasons, and process fluctuations.

(2) Industrial wastewater treatment

Industrial wastewater often involves fields such as petrochemicals, electroplating, dyeing, papermaking, pharmaceuticals, food processing, and leather. Such wastewater contains many organic compounds, surfactants, emulsions, and foaming agents, resulting in persistent foam. The new generation of silicone-based defoamers, through molecular design, delivers both extremely fast defoaming and long-term suppression, perfectly suited to tough and complex systems in many industrial processes.

(3) Chemical Cleaning and Circulating Water Treatment

In circulating water systems and chemical cleaning across industries such as refrigeration, thermal power, boilers, and cement, foam persists due to scale inhibitors and detergents. Silicone defoamers with excellent foam control and dispersibility are added to improve heat exchange, equipment safety, and overall process stability.

(4) Biorefinery and Pharmaceutical Wastewater

Wastewater from biopharmaceutical, fermentation, and brewing industries exhibits severe foam due to microbial metabolism and high organic materials. Conventional antifoaming agents may interfere with the process by causing pollution and antibacterial effects. Silicone defoamers, as weak antibacterial and non-residual agents, are the preferred medium for sensitive and critical waste treatment applications.

(5) Textile Dyeing, Papermaking, and Textile Industry Wastewater

Industries including textile dyeing, paper mills, and textiles have high foam loads in washing tanks, sedimentation ponds, and papermaking stock. Silicone defoamers provide superior foam control, reducing energy use and breakage rates.

(6) Other Special Water Treatment Fields

In fields needing strict foam control, such as landfill leachate, agriculture, electronics, and seawater desalination, silicone-based defoamers are a main solution owing to their environmental friendliness and excellent performance throughout a broad range of system requirements.

6. What is the market trend for silicone defoamers?

(1) Current Status of the International Market

According to MarketsandMarkets, the global defoamer market exceeded 7 billion USD in 2023, with silicone-based defoamers accounting for over 30% of the market share and growing fast. The United States, Germany, and Japan are leaders, with test methods now focusing on multifunctionality and environmental safety. Asia-Pacific countries are rising in demand, especially China and India.

(2) Green, Intelligent, and Functional Integration

The market for silicone defoamer is moving toward “three high” requirements: green biodegradability, high efficiency at low concentrations, and no side effects. Simultaneously, defoamers are being integrated with digital operations and remote monitoring for intelligent and optimized usage. New silicone-based defoamers combine defoaming, flocculation, and oil suppression for multifunctional performance across all wastewater systems.

7. How to enhance the advantages of silicone defoamers?

With industrial upgrading, stricter policies, and smart manufacturing development, the demand for efficient, green, and intelligent defoaming solutions in wastewater foam control is stronger than ever. Silicone antifoam products, with their dual defoaming and anti-foaming effects, environmental compatibility, and process adaptability, have become foundational to the future of waste treatment. How to enhance product competitiveness?

XJY Silicones is among China's leading manufacturers of silicone MQ resins and VMQ silicone, with over 30 years of R&D and manufacturing experience in the organic silicone chemistry industry, and more than 15 related patents. Our silicone raw materials can meet the needs of the defoamer field and support diversified customized solutions.