In implant dentistry and precision fixed prosthodontics, the quality of the dental impression directly controls the fit and long-term stability of the final restoration. For years, studies have compared different clinical techniques, such as PVS putty-wash methods versus intraoral scanners, mainly focusing on accuracy.

Well-designed polyvinyl siloxane (PVS) impressions based on vinyl silicone polymers and silicone resin can meet demanding accuracy requirements for single implants and high-precision fixed cases, and are often comparable to modern digital impressions.

For upstream silicone raw material manufacturers and dental material producers, however, the more important point is not just “which impression method is better,” but: how to use better base polymers such as vinyl silicone resin, silicone oil, and liquid silicone rubber, to give dental impression materials higher accuracy, easier handling, better patient comfort, and more robust stability, so that they truly support the upgrade of the whole dental industry.

- Introduction to Silicon, Silicones, and Density

- Core Advantages of Vinyl Silicone in PVS Dental Impression Materials

- What Kind of Vinyl Silicone Does the Dental Industry Really Need?

- Application Opportunities for Vinyl Silicone in the Dental Field and Beyond

- How to choose dental silicone material?

1 Introduction to Silicone, Silicones, and Density

From a materials-science point of view, vinyl silicone belongs to the family of silicones, which are polymers based on silicon and oxygen. In nature, naturally occurring silicon is not found as liquid silicon but mainly as silica and silicate minerals; in the earth’s crust, it is combined with oxygen in hard, rock-like compounds.

At the atomic level, elemental silicon forms a crystal structure with tetrahedral coordination of silicon atoms, similar to germanium. Single-crystal wafers with precisely controlled impurity levels and doping are the heart of modern integrated circuits, where even tiny variations in the atomic arrangement can strongly affect electrical performance.

Under standard conditions of temperature and pressure, this crystalline solid has a density of around 2.33 g/cm³. In a cubic meter of such material, you can calculate the mass to be more than two tons.

Silicone materials are very different. In silicones, silicon atoms are bonded to oxygen and organic groups to form flexible polymers that behave more like rubber and plastics. Silicone rubber and liquid silicone rubber are soft, inert elastomers with unique properties such as high dielectric strength, good flow during the curing process, and excellent stability when exposed to air, moisture, and heating. Commercial silicone fluids are often characterized by viscosity in cSt (centistokes), and can be blended with other materials or additives to tune processing and performance.

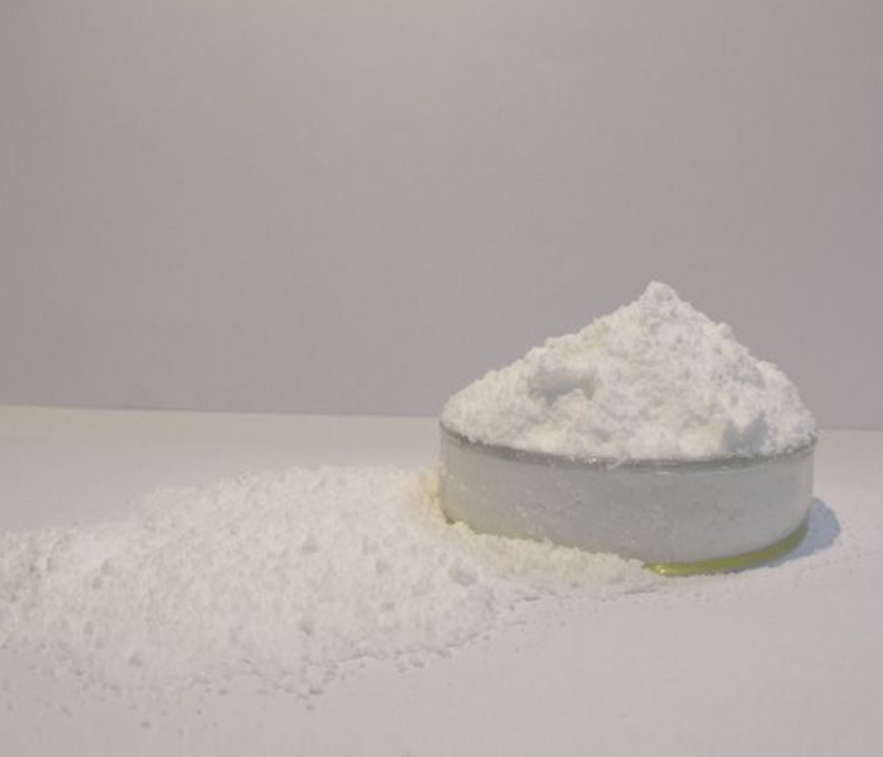

XJY-8206 Vinyl methyl silicone resin is a polycondensate from four functional group siloxane(Q) and one functional group methyl siloxane(M), the molar mass is generally 2500-5000g/mol, the molecular structure of M and Q chain ratio, and the structural nature of the M decision resin applications.

From a practical materials perspective, engineers often talk about silicone density, specific gravity, and relative density. Under standard conditions, most silicone rubbers and liquid vinyl silicone compounds show an average density in the range of about 0.95–1.25 g/cm³, close to water. Per cubic meter, this corresponds to a weight of roughly 950–1250 kg. The exact values reported in technical data depend on many factors:

the presence of reinforcing fillers like silica or even heavy pigments;

the type of vinyl silicone polymer and other materials used in the formulation;

the methods of mixing and degassing, which reduce voids and trapped air and can be further enhanced under higher pressures;

The final volume is achieved after curing and shrinkage.

These density values are often referred to as “silicone density” and are commonly used to control batching, calculate production output, and keep mechanical properties consistent from one lot to the next. In impression compounds, if the density is too low, the material may not fully sink into narrow sulcus regions; if it is too high, excessive mass and hardness can negatively affect handling. Getting this balance right, together with viscosity and crosslinking density, is one of the key features of a good vinyl silicone formulation.

All these background facts about silicon, silicones, and density explain why vinyl silicone-based PVS systems are so attractive for dental use: they combine the atomic-level stability of silicon-oxygen networks with the macroscopic flexibility and flow of engineered polymers.

2. Core Advantages of Vinyl Silicone in PVS Dental Impression Materials

PVS dental impression materials are built on a network of vinyl-functional silicone polymers and vinyl silicone resins. For formulation chemists, this network decides whether the impression material is “easy and reliable” in the mouth.

2.1 Dimensional Stability, Heat Resistance, and Low Shrinkage

Vinyl silicone systems cure through a platinum-catalyzed addition reaction and do not release volatile by-products. As a result, the volume shrinkage is very low compared with condensation-cure systems and many traditional rubbers. At the same time, they offer excellent heat resistance and weather resistance, which is important for storage, transport, and long-term performance.

By choosing vinyl silicone polymers with suitable molecular weight, vinyl content, and crosslinking density, the cured PVS forms a stable three-dimensional network. This allows the impression to keep its dimensions during:

- removal from the mouth

- gypsum pouring

- transport to the lab

- storage before the model is scanned or poured again

For dental labs that ship work over long distances or pour more than one model, this dimensional stability, together with predictable density and shelf life, is crucial.

2.2 Mechanical Properties: Elastic Recovery, Tear Strength, and Tensile Strength

A dental impression has to pass over undercuts, contact points, and implant components, then spring back to its original shape without permanent distortion. At the same time, it must resist tearing in thin areas around the gingival margin.

By combining different structures of vinyl silicone fluids, vinyl silicone resin, MQ resin, and reinforcing fillers, formulators can tune crosslinking density and achieve a balance between:

- softness and hardness (patient comfort and easy tray removal)

- elastic recovery and tensile strength (faithful reproduction of details)

- Tear strength (protection of fine flash and margins under high local stress)

The resulting physical properties define how the product behaves in real applications. Well-designed vinyl silicone systems give an impression that is easy to remove yet holds the sharp detail needed for implant and crown margins.

2.3 Controllable Flow, Viscosity, and Thixotropy

Classic PVS systems include putty, medium-body, and light-body viscosities. The rheology of each grade is heavily influenced by the vinyl silicone raw materials.

Low-viscosity silicone oil and vinyl silicone fluids improve flow and wetting for light-body “wash” materials, helping them penetrate the sulcus and fine anatomy.

Higher viscosity, branched or partially resin-modified base polymers provide body and support in tray materials, keeping the impression stable under pressure.

By supplying a portfolio of vinyl silicone polymers with different viscosities and vinyl functionality, raw material manufacturers allow dental companies to design putty-wash systems that balance working time, setting time, and intraoral handling. Additives such as surfactants and thixotropy modifiers can be combined to tune processing and coating behavior without compromising mechanical strength.

2.4 Chemical Resistance and Hydrophilicity Options

Traditional silicone rubber impressions are hydrophobic, which can make it difficult to capture details in the presence of saliva or small amounts of blood. Modern PVS products overcome this by introducing hydrophilic side chains or by blending special surfactant systems into the vinyl silicone network.

At the same time, vinyl silicone materials show very good chemical resistance to many mild acids, bases, and cleaning agents, which helps them maintain properties during disinfection and storage. For dental manufacturers, access to hydrophilic yet chemically robust vinyl silicone building blocks is a key step toward premium “hydrophilic PVS” impression materials.

2.5 Compatibility with Gypsum, Resin, and Digital Workflows

Because of their chemical inertness and surface properties, vinyl silicone impression materials show:

Good release from dental stone

low interaction with most 3D-printing resins

stable optical behavior (including refractive index) when scanned with lab scanners

This makes vinyl silicone PVS suitable not only for traditional gypsum models, but also for workflows where:

The impression is poured,

The stone model is scanned,

The data is imported into CAD/CAM systems.

In many clinics and labs that are still transitioning from conventional to fully digital processes, vinyl silicone impressions are the bridge between two worlds.

3. What Kind of Vinyl Silicone Does the Dental Industry Really Need?

From a raw material supplier’s perspective, serving the dental impression and silicone rubber market means designing a vinyl silicone portfolio that directly matches the needs of dental material manufacturers.

3.1 Vinyl Silicone Fluids and Base Polymers

Low-viscosity vinyl silicone fluids are used to adjust flow and improve wetting in light-body materials. Higher molecular-weight or lightly branched base polymers are used to increase elasticity and recovery.

By offering a wide viscosity range and clearly specified vinyl content, suppliers can help formulators quickly locate the right combination for:

putty

heavy-body / tray materials

medium and light-body wash materials

Combining density values, viscosity data, and other properties in one information package makes it easier for manufacturers to design formulations and processing conditions.

3.2 Vinyl MQ Silicone Resins and Silicone Resins

Vinyl MQ silicone resins act as a “hard skeleton” and reinforcing points in the network. They help to create the impression:

resist collapse under tray pressure

Keep the tray material dimensionally stable at different temperatures

improve edge sharpness and detail reproduction

By adjusting M/Q ratio, vinyl content, and solvent type (for example, systems based on xylene or other compatible solvents), suppliers can create resins optimized for:

high-hardness putty materials

medium-hardness tray or monophase materials

coatings and potting compounds where mechanical strength and insulation are required

These resins, together with suitable fillers at micron-scale particle size, give manufacturers strong tools to fine-tune mechanical characteristics and specific gravity.

3.3 Platinum-Catalyzed Systems and Crosslinking Density

Dental impression materials must meet strict clinical timing requirements: a workable mixing time, a predictable intraoral setting time, and a reliable shelf life. Vinyl silicone formulations are generally cured by a platinum catalyst, and the reaction proceeds as an addition cure between vinyl groups and Si-H groups.

Vinyl silicone suppliers can support this by offering matched platinum-catalyzed systems and inhibitor packages that:

control crosslinking density and hardness

keep shelf life stable during storage in a cool, dry, and well-ventilated place

avoid catalyst poisoning from common dental adhesives or other materials used chairside

A well-matched cure system reduces batch variability and gives dentists a more consistent experience at the chairside.

3.4 Functional Vinyl Silicone Units for Hydrophilic and Specialty Grades

By building PEG segments, hydroxyl groups, or other hydrophilic units into the vinyl silicone chain, raw material suppliers can deliver functional polymers that:

increase the surface wettability of the impression

keep mechanical strength acceptable

improve detail reproduction in moist conditions

Such functional vinyl silicone polymers are the base for next-generation hydrophilic PVS impression materials. Carefully chosen additives and processing methods allow manufacturers to tailor performance for a variety of clinical applications.

4. Application Opportunities for Vinyl Silicone in the Dental Field and Beyond

Beyond classic PVS impression materials, vinyl silicone systems have broader potential in dental and related industries.

4.1 Dental Liners, Potting, and Electronics Around the Mouth

By lowering crosslink density and using softer fillers and plasticizers, vinyl silicone elastomers can be formulated as:

soft liners and elastic relining materials for dentures

potting and encapsulation compounds for small electronics near the oral cavity, where insulation, chemical resistance, and flexibility are needed

protective layers on small circuit boards used in medical and dental devices

These products benefit from the same insulation, weather resistance, and mechanical properties that make silicone resins attractive in aerospace, transport, and general electronics.

4.2 Temporary Sealing and Barrier Materials

Thanks to their elasticity and low surface energy, vinyl silicone materials can be used as:

temporary sealing materials during endodontic treatment

gingival barriers or isolation layers in bleaching procedures

protective covers in various restorative procedures

They provide controlled sealing and easy removal without damaging tooth structure.

4.3 Supporting Digital Dentistry and 3D Printing

As digital dentistry grows, more labs use 3D-printing resins to produce models and custom trays. Stable vinyl silicone impressions combined with scan-friendly surfaces are an important entry point to the digital workflow.

In the future, there is also potential to develop vinyl silicone-based flexible printing materials for custom oral devices, splints, or protective mouthpieces, further extending the role of vinyl silicone in digital dental manufacturing.

4.4 Oral Protection and Medical Accessories

Because of their biocompatibility and soft elasticity, silicone systems are already used in bite registration materials, mouthguards, and sleep-apnea devices. Vinyl silicone chemistry can help fine-tune hardness, tensile strength, and durability for such long-term oral appliances, giving designers better control over comfort and performance.

5. How to choose dental silicone material?

Progress in dental impression technology does not depend only on better techniques or more advanced scanners. It also relies on continuous improvements in the vinyl silicone material system that forms the core of PVS dental impression materials.

Polyvinyl siloxane impressions based on vinyl silicone polymers have already proven their dimensional accuracy and long-term stability in clinical practice. By carefully designing vinyl silicone fluids, vinyl silicone resins, MQ resin, fillers, and matched platinum-catalyst systems, raw material manufacturers can further optimize:

- mechanical properties and tear strength

- hydrophilicity and chemical resistance

- handling time and setting profiles

- compatibility with gypsum, 3D-printing workflows, and other materials

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone cosmetics field and support the provision of diversified customized solutions.

![]()