In the modern healthcare industry, silicone materials have become key enabling materials for a wide range of medical devices and biomedical applications. Thanks to their unique Si–O backbone, silicone resins and silicone rubbers combine excellent thermal stability, chemical stability, flexibility, and biocompatibility in one material. How Are Silicone resins for medical applications in Modern Healthcare?

At the same time, properly formulated medical-grade silicone and RTV silicones (room-temperature-vulcanizing) offer strong mechanical properties, long service life, and low risk of leachables. As a result, silicone resins for medical applications are now a key material family for medical applications, from medical implants and medical adhesives to drug delivery systems, wearable devices, and flexible electronics.

- What Makes Silicone Materials Suitable for Biomedical Use?

- How Are Silicone Resins and Elastomers Used in Medical Coatings?

- In Which Implants Are Silicone Materials Commonly Used?

- How Are Silicone Materials Used in Medical Applications?

- How Do Silicone Elastomers Support Cosmetic Reconstruction?

- What Roles Do Silicone Materials Play in Nerve Repair, Wound Care, and Drug Delivery Systems?

- How Can Silicone Resins and Elastomers Be Modified to Resist Biofilms?

- How Is 3D Printing Changing the Use of Silicone in Medical Devices?

- What Do These Trends Mean for Silicone Resin Suppliers and the Healthcare Industry?

- How to make your medical products better?

1. What Makes Silicone Materials Suitable for Biomedical Use?

One reason silicone medical solutions are so attractive is their outstanding mechanical properties and chemical stability. The Si–O bond in silicone elastomers has a higher bond energy than the C–C bonds in most organic polymers, so silicone rubber can retain flexibility and strength under high temperature, sterilization, and aggressive fluids. For long-term implants and implantable devices, this durability is crucial.

A second advantage is biocompatibility. High-purity medical-grade formulations are engineered so that their functional groups, extractables, and residual catalysts are tightly controlled. As a result, silicone gels, elastomers, and silicone resin coatings show low inflammatory responses when in contact with biological tissues, and they support normal cell proliferation on or near the surface. This combination of safety and performance is why silicone is commonly chosen for critical devices.

Third, the process flexibility of silicone makes the development of customized medical devices easier. Flexible silicone elastomers can be processed at room temperature or moderate temperatures using injection molding, compression molding, extrusion, direct printing, soft lithography, additive manufacturing, and other 3D printing or rapid prototyping routes. By selecting suitable curing process conditions and, when needed, post-curing, engineers can achieve the required properties—from soft gels to tough elastomers—while maintaining low shrinkage and optimal performance.

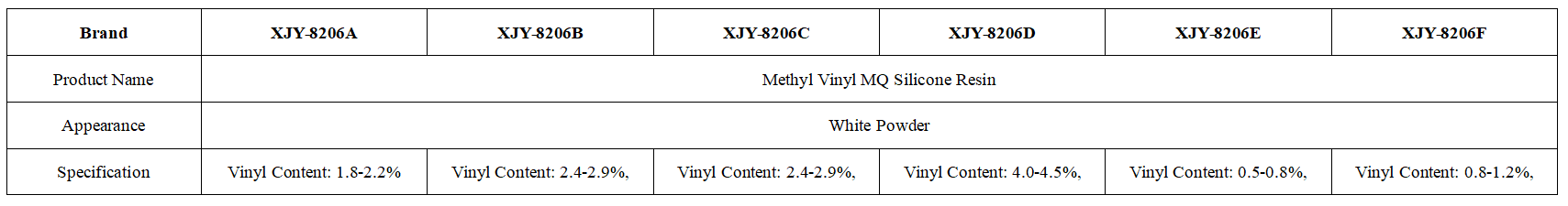

XJY-8206 Methyl Vinyl MQ Silicone Resin

It is a solid powder resin that can be used as a reinforcing filler for additive-molded silicone rubber (highly concentrated rubber), with high transparency and high hardness.

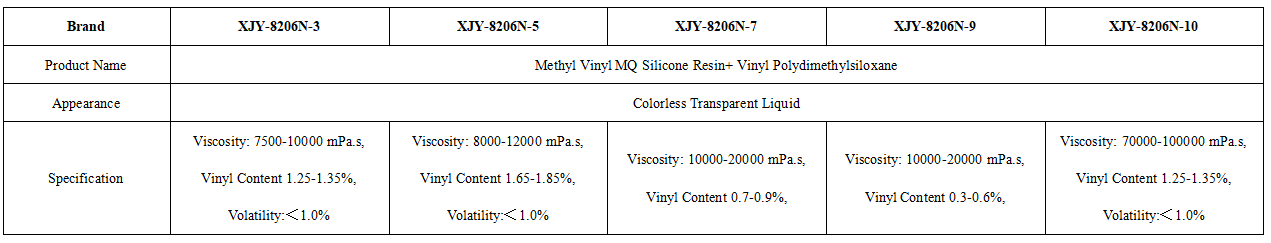

XJY-8206N Methyl vinyl MQ silicone resin + vinyl polydimethylsiloxane

It is a colorless and transparent liquid silicone rubber LSR, composed of vinyl MQ silicone resin and vinyl silicone oil. It can be used with other additives in liquid silicone rubber(high consistency rubber) and also has good reinforcing and hardening properties, widely used in the medical field and electronics (computer chips).

2. How Are Silicone Resins and Elastomers Used in Medical Coatings?

In many medical procedures, simple silicone rubbers and silicone elastomers act as coatings and tubing that quietly protect the patient. A very thin layer of medical-grade silicones on hypodermic needles, syringes, or glass barrels gives a lubricious surface that reduces insertion force and trauma to the skin. These solutions create smooth contact and watertight seals between moving components, allowing devices to function reliably.

Within fluid-handling medical devices, silicone coatings provide inert surfaces that resist protein adsorption and chemical attack. This is important for blood collection systems, dialysis lines, and infusion sets, where silicone materials help maintain accuracy and cleanliness throughout the medical procedure. Their ability to form thin, defect-free films also supports medical adhesives and encapsulants that bond glass, metal, and plastics without compromising clarity or sterility.

Silicone tubing based on flexible silicone elastomers is used in oxygenators, heart-lung machines, and other life-support devices. The combination of gas permeability, elasticity, and chemical stability makes such tubing suitable for continuous contact with blood and other body fluids, while the molding process can be tuned to provide smooth internal surfaces and precise wall thicknesses.

3. In Which Implants Are Silicone Materials Commonly Used?

Medical implants represent one of the most visible medical applications for silicone. Ventricular shunts for hydrocephalus use silicone tubing that must remain flexible and biostable for years inside the body. Pacemaker leads and other implantable devices depend on silicone rubbers and silicone elastomers as insulating jackets, where long-term dielectric strength and thermal stability are essential.

In soft-tissue reconstruction, silicone gels and crosslinked resins are widely used for breast implants and facial implants. Here, the form must feel natural, match the surrounding skin, and maintain shape without excessive hardening or leakage. Proper curing process control and post-curing steps help reduce residual low-molecular-weight species and minimize inflammatory responses around the implant.

Silicone is also found in small joint prostheses, cushioning pads, and other medical implants where mechanical properties like elasticity, tear resistance, and high precision fit are crucial. Compared with many other materials, silicone products offer low shrinkage during molding, reliable watertight seals, and an excellent safety record in the healthcare field.

4. How Are Silicone Materials Used in Medical Applications?

In eye-care medical applications, contact lenses made from silicone hydrogels demonstrate how silicone materials can be tailored for both comfort and performance. The incorporation of silicone segments into the network gives far higher oxygen permeability than conventional hydrogels, which directly benefits wound healing and corneal health.

These lenses must balance mechanical properties, lubrication, and cleanliness. Surface modification or plasma treatment can increase wettability and adjust functional groups at the surface, improving comfort during contact with the delicate tissues of the eye. At the same time, manufacturers must control cell proliferation, protein deposition, and microbial adhesion to limit the risk of infection.

Beyond lenses, silicone oils and soft elastomer components also appear in retinal surgery tools and other ophthalmic devices, where clarity, chemical stability, and compatibility with biological tissues are vital.

5. How Do Silicone Elastomers Support Cosmetic Reconstruction?

In maxillofacial and cosmetic reconstruction, silicone elastomers and silicone gels enable highly realistic prostheses. Custom ear, nose, and orbital prostheses made from soft but durable silicone rubber can be colored and textured to blend smoothly with surrounding skin.

These applications often rely on compression molding or injection molding to create fine detail, followed by careful finishing for a realistic appearance. Because silicone offers good mechanical properties, low shrinkage, and high precision, it is suitable for thin edges and complex shapes that are comfortable in long-term daily wear.

As next-generation reconstruction solutions emerge, designers increasingly integrate flexible silicone elastomers with flexible electronics and wearable devices, for example, sensor-embedded facial prostheses that monitor wound healing or pressure points. In such development, silicone resins for medical applications act as the key material matrix that protects sensitive components while still conforming to the body.

6. What Roles Do Silicone Materials Play in Nerve Repair, Wound Care, and Drug Delivery Systems?

Silicone tubes can serve as nerve guidance conduits, helping regenerating axons grow across a gap between severed nerves. Their mechanical properties and surface chemistry can be tuned so that scar tissue growth is limited while nerve cells have a protected channel to cross. Similar tubing concepts are used in drug delivery systems, where silicone gels or elastomers control diffusion of active ingredients in controlled-release implants.

In wound care, soft silicone foams and medical adhesives are used in dressings that adhere gently to fragile skin without causing extra trauma during removal. These silicone products can provide watertight seals around chronic wounds while still allowing moisture vapor transmission, supporting wound healing, and reducing the risk of infection.

Silicone matrices are also being investigated as scaffolds for cell proliferation and tissue regeneration. Here, combinations of silicone resin and bioactive fillers create solutions for wound healing and regenerative medical applications that bridge the gap between traditional bandages and advanced biomedical applications.

7. How Can Silicone Resins and Elastomers Be Modified to Resist Biofilms?

Because silicone is hydrophobic, its surfaces can attract proteins and microorganisms, leading to biofilm formation on medical-grade tubing and devices. To address this, researchers modify silicone materials in several ways.

Passive strategies include grafting hydrophilic polymers or zwitterionic layers onto the surface via plasma treatment or chemical grafting. These coatings change the form and chemistry of the outermost layer, improving lubricity and reducing bacterial attachment.

Active strategies embed antimicrobial agents within the silicone resin or elastomer matrix. Silver or zinc nanoparticles, iodine complexes, antibiotics, or antimicrobial peptides can be dispersed in silicone gels or RTV silicones, allowing slow release over time. Proper curing process and post-curing are important so that the material maintains its mechanical properties while delivering the required biocidal effect in medical applications and wound care.

8. How Is 3D Printing Changing the Use of Silicone in Medical Devices?

Modern additive manufacturing and 3D printing technologies are transforming how silicone materials are processed into customized medical devices. Traditional PDMS systems were difficult to print due to viscosity and slow curing, but new silicone medical inks and resins are enabling direct printing of soft structures.

Using rapid prototyping techniques such as direct-ink-writing, soft lithography, printing into support baths, and hybrid molding process workflows, engineers can achieve high precision structures with low shrinkage and complex internal channels. These methods are especially valuable for microfluidic devices, soft robotic actuators, and flexible electronics integrated into wearable devices and medical implants.

Some systems combine 3D-printed silicone with extrusion or injection molding to create multiple applications from the same material, such as patient-specific airway splints, sensor-embedded or thoses, and next-generation soft robotics for minimally invasive medical procedures.

9. What Do These Trends Mean for Silicone Resin Suppliers and the Healthcare Industry?

For suppliers of silicone resins for medical applications, these trends highlight huge opportunities. Medical OEMs are looking for silicone resin and silicone elastomers that support both general-purpose uses and highly specialized medical devices. Grades with tailored functional groups, viscosity, and cure profiles are needed for injection molding, compression molding, extrusion, coating, and 3D printing.

To support optimal performance, suppliers must understand not only the base materials but also how molding, curing process,post-curing, and manufacturing conditions affect properties such as modulus, tear strength, thermal stability, chemical stability, and adhesion. Working closely with device designers on development projects allows resin producers to provide solutions that are truly suitable for specific medical applications, from breast implants and long-term implants to wearable devices, wound care products, and drug delivery systems.

10. How to make your medical products better?

Ultimately, silicone resins, silicone rubbers, and flexible silicone elastomers have become a key material platform for the next generation of medical and healthcare devices. By combining excellent mechanical properties, robust processing, versatile molding process options, and strong biocompatibility, they enable engineers to design safer, more reliable, and more comfortable silicone products for patients around the world.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone PSA field and support the provision of diversified customized solutions.

![]()