High-temperature service—exhaust pipes, flues, ovens, boilers, furnace shells, and heaters—demands coatings with dependable heat resistance, weather resistance, water resistance, and long-term chemical resistance. Why did you choose methyl phenyl silicone resin?

Among silicone resins, the standout methyl phenyl silicone resin combines a robust Si–O backbone with methyl and phenyl groups that upgrade thermal stability, anti-yellowing, and moisture blocking.

There are six aspects to introducing methyl phenyl silicone resin:

- Why Methyl-Phenyl Silicone Resin?

- Formulation Strategies for Coatings Engineers

- Key Applications & Value

- Practical Selection & Validation

- Comparison Framework

- How to make coating performance better?

1. Why Methyl-Phenyl Silicone Resin?

(1)Higher thermal ceiling & cycle durability

Strong Si–O bonds and a flexible network help the film remain stable through heat shock and temperature swings; high heat resistance and excellent thermal stability are intrinsic features.

Phenyl groups (including high phenyl content or high phenyl silicone resin grades) raise thermo-oxidative stability and color hold, protecting appearance and gloss under severe temperatures and UV.

(2)Weatherability + hydrophobicity

Methyl substitution lowers surface energy, boosting water resistance and soil release while limiting moisture uptake.

Phenyl substitution improves UV durability (UV resistance) and heat-ageing; outdoor hot spots (stacks, exhaust pipes, furnace doors) keep their performance longer.

(3)Adhesion, mechanics, and electrical profile

Excellent compatibility with organic resins (epoxy, acrylic, polyester) enables hybrids with good compatibility, excellent compatibility, and tuned viscosity and mechanical properties/mechanical strength.

The network structure also supports electrical insulation needs around hot equipment where dielectric behavior matters.

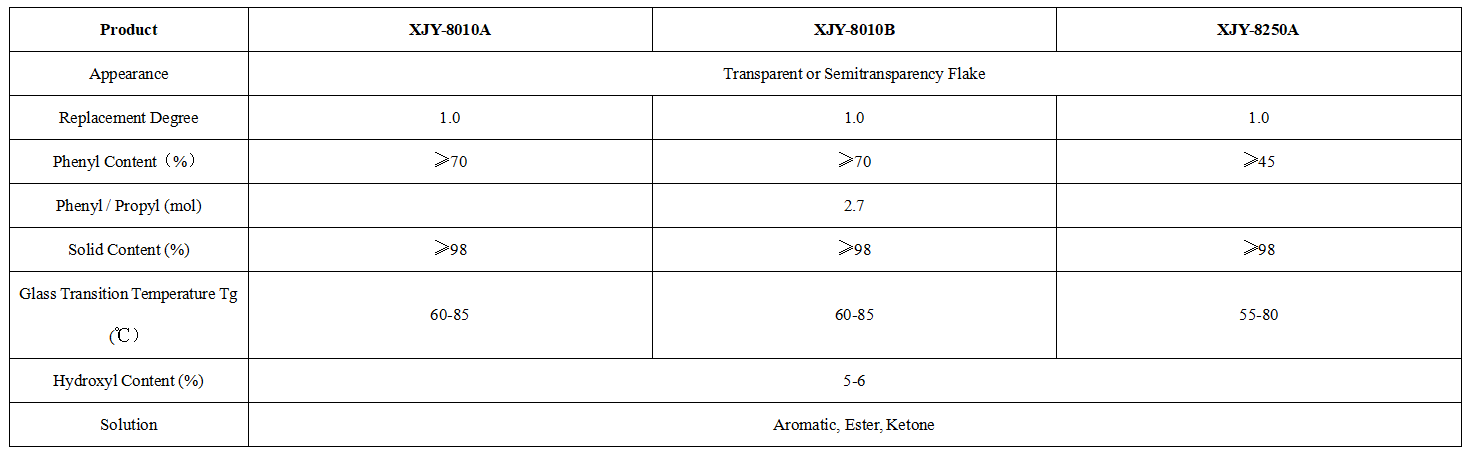

XJY-8010A/B/8250A Methyl Phenyl Silicone Resin

Methyl phenyl silicone resin can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat resistance, which hardly decomposes at 200℃ or even higher temperatures, and can be used to prepare all kinds of heat-resistant coatings, with heat-resistant insulation grade up to H class. Silicone resins have excellent weathering and UV resistance and can be used for powder and liquid coatings. Silicone resins have excellent weather resistance and provide all-around protection for equipment. Silicone resins have excellent weatherability and good adhesion. Silicone thin layers also have excellent weather resistance, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties.

(4)Corrosion & chemical resistance

Films deliver excellent resistance to oils, solvents, and industrial gases; barrier integrity helps in salt spray-prone sites.

Silicone matrices are suitable for aggressive service while maintaining clarity in clearcoats and good appearance in pigmented coatings/paints.

2 Formulation Strategies for Coatings Engineers

(1)Resin chemistry & cure

Condensation-cure routes give proven heat and weather durability with reliable network forms/binder integrity.

Addition curing formulations (Pt-catalyzed) provide faster cures and higher crosslink density; typical tools include a platinum catalyst and silicon hydride crosslinker.

Blends and modifications with organic resins (e.g., epoxy) allow you to tailor hardness (hard films), flexibility (low temperature flexibility when needed), adhesion, and baking windows.

(2)Pigments/fillers & barrier design

Use lamellar/platelet fillers (mica, aluminum flakes) or ceramic fillers to create a tortuous diffusion path and improved barrier properties.

For high-salt or condensate environments, a multi-coat build (primer/mid/top) increases screening against ions and enhances chemical resistance and weather resistance.

(3)Rheology, solvents & film formation

Balance viscosity for spray or brush; choose carriers (e.g., toluene, where compliant) that enable flow, leveling, and defect control at bake.

High-solids, addition or condensation formulations can be adapted for on-site work; aim for dense films without micro-cracking at hot spots.

(4)Processing & application

Compatible with spray/roll/brush, these products/types of silicone resins are widely used in hot service applications and products that require durable binder systems.

Clear and pigmented forms are common; hybrid polymers or silicone-organic adhesives can be part of the system where joining or sealing is required.

3 Key Applications & Value

Exhaust systems & flues: Heat resistant coatings/paints hold color and barrier under alternating heat and condensate; easy clean-down from soot or oil.

Industrial furnaces & heat exchangers: Stable under cycling; improved fouling resistance reduces downtime.

Power & petrochemical hot-end parts: Phenyl silicone resin matrices manage UV plus chemical load; coatings remain stable under mixed atmospheres.

Home/consumer heat-exposed parts: Anti-yellowing and detergency resistance protect both function and finish; transparent grades maintain clarity and gloss.

4 Practical Selection & Validation

(1)Surface preparation first

Standard degrease/derust/roughen to secure mechanical interlocking; adhesion is the top predictor of durability.

Choose primers with good compatibility with the substrate and with the silicone binder in the mid/top coats.

(2)Coating architecture & thickness

Primer / mid-coat / topcoat architecture: adhesion+anti-corrosion (primer), barrier+stress control (mid), heat resistant/weather resistance + repellency (top).

Manage intercoat stress so high DFTs stay dense without cracking; tune viscosity and bake to avoid defects.

(3)Combined-stress testing

Validate heat resistance with thermal stability under cycling, humidity, and corrosive media; include salt spray where relevant.

In marine-adjacent or condensate environments, prioritize barrier fillers and sealing of edges/penetrations.

(4)Maintenance & cleaning

Low surface energy aids soil release; periodic inspections and small-area repairs stretch lifecycle and protect appearance.

5 Comparison Framework

Versus generic silicone resin grades: methyl phenyl silicone provides excellent heat resistance with better anti-yellowing and color/gloss retention at high temperatures.

Versus conventional organic resins: markedly higher thermal stability, chemical resistance, and outdoor endurance.

Versus silicone-modified organics: methyl-phenyl silicone excels as a high-temperature binder/topcoat; co-use when extra adhesion or specific mechanics are required

6. How to make coating performance better?

Choosing methyl phenyl silicone resin as the primary binder in heat-resistant coatings delivers a systematic advantage: excellent heat resistance, durable weather resistance, strong chemical resistance, low-energy surfaces with better cleanability, and robust mechanical properties. With proper formulations, barrier fillers, tuned viscosity, and either condensation or addition curing formulations, these silicones protect hot assets—from exhaust pipes to ovens and boilers—and keep them looking good while they work.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone coating field and support the provision of diversified customized solutions.