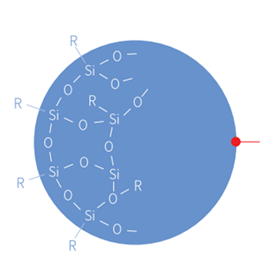

Silicone microspheres are a kind of superfine spherical powder material with organic and inorganic characteristics, three-dimensional network spherical shape. It has good optical properties, dispersion, lubricity, heat resistance, excellent silky feel, and so on.

![]()

As a light diffusing agent, silicone microspheres are widely used in LED lampshades and bulb injection materials to scatter the light source and produce soft light. The main influencing factors of its use effect are as follows:

- Particle size;

- The refractive index of the material;

- Material thickness and shape;

- Spherical regularity, etc.;

1. Particle size

Under the conditions of the same type of material and the same amount of light-diffusing agent of the silicone microspheres, the smaller the particle size of the silicone microspheres is, the more the number of particles is, the more times the light is deflected, the greater the diffusivity is, and the higher the haze is. In other words, to obtain the same haze, the addition ratio of the silicone microspheres light diffusion particles can be reduced, which can reduce the cost. However, the larger the number of light diffusion particles of the silicone microspheres, the lower the light transmittance. Therefore, it is necessary to determine the amount of light-diffusing agent to be added according to the silicone light diffusing agent with different particle sizes and the changes in haze and light transmittance.

XJY Silicones can provide XJY-801 Polymethylsilsesquioxane(PMSQ) in different particle sizes of silicone microspheres.

| Name | Type | Appearance | Average Particle Size (μm) | Refractive index | Heat resistant(℃) |

| Polymethylsilsesquioxane | XJY-8011 | White powder,flow freely | 1 | 1.42-1.45 | >400 |

| XJY-80113 | White powder,flow freely | 1.3 | >400 | ||

| XJY-80116 | White powder,flow freely | 1.6 | >400 | ||

| XJY-8012 | White powder,flow freely | 2 | >400 | ||

| XJY-8013 | White powder,flow freely | 3 | >400 | ||

| XJY-8015 | White powder,flow freely | 5 | >400 | ||

| XJY-801105 | White powder,flow freely | 15 | >400 | ||

| XJY-80120 | White powder,flow freely | 20 | >400 |

2. The refractive index of the material itself

Haze refers to the deflection of light when passing through the interface of two materials with different refractive indexes, resulting in diffusion. Therefore, the greater the difference in refractive index between materials, the greater the deflection angle of light after passing through, and the higher the efficiency of haze generation.

![]()

For example, the refractive index of PS and PC is 1.59, the refractive index of PMMA is 1.49, and the refractive index of silicone microspheres is 1.42~1.45, so the number of silicone microspheres light diffusion agent required to achieve the same haze of PS and PC It is much less than that of PMMA. This is why the amount of PMMA light diffuser added is 2-3 times more than that of silicone microspheres.

3. Material thickness and shape

The light diffusion materials on the market mainly come in two forms: lamp panels and bulbs. The lamp panels are conventionally divided into 1mm, 1.5mm, and 2mm thickness. Although the materials may be the same, the amount and particle size of silicone microspheres' light diffusion agent required is different.

![]()

Taking standard 2μm silicone microspheres light diffusion particles, with a certain amount of addition, the 1mm light diffusion plate is closely arranged in the thickness direction, and it is impossible to exceed 1000μm / 2μm = 500 silicone microspheres light diffusion particles at most. Moreover, the material itself needs to be bonded between the particles. The 1.5mm and 2mm light diffusion plates can arrange up to 750 and 1000 light diffusion particles of silicone microspheres. Therefore, in comparison, the haze and light transmittance will deviate from each other. In this case, the appropriate amount of light diffusion agent of silicone microspheres should be determined by combining the haze and light transmittance, or use smaller diameter silicone microspheres light diffusion particles to compensate for light deflection. For example, using 1.5μm silicone microspheres light diffusion particles to prepare the 1mm thick board can also achieve a good haze.

However, as far as the bulb is concerned, because the lamp bead is far away from the lampshade, the haze requirement will be reduced. In addition, the bulb has a large reflected light area and strong reflection ability, so the light loss is very low, so the light is transmitted. The rate is high. Therefore, a relatively small amount of addition can achieve better light transmittance and haze. Generally, PC materials are added by 0.3~0.5%.

4. Spherical regularity of silicone microspheres light diffusion particles

The more spherical silicone microspheres light diffusing agent particles, the more the light deflects on the surface of the sphere, and the more regular reflection angles. Therefore, the prepared light diffusing material has higher haze and better use effect, and lower addition.

![]()

Compared with PMMA light diffusion particles, the advantages of silicone microspheres light diffusion particles are as follows:

- The refractive index of PS and PC is 1.59. Since the refractive index of PMMA microspheres (1.49) is higher than that of silicone microspheres (1.43), the amount of PMMA silicone microspheres light diffuser required to achieve the same haze is much higher than the organic silicon microspheres, and the cost is high;

- PMMA light diffusion particles have poor heat resistance, because the main chain of silicone microspheres is Si-O-Si, while the main chain of PMMA microspheres is C-Cand C-O. The bond energy of Si-O-Si is about 30% higher than that of C-C and C-O, so the heat-resistant effect of silicone microspheres light diffusion agent is better;

- PMMA has a short service life and is easy to yellow. Because PMMA is polymerized by double bond radicals, double bonds will remain on the surface of the microspheres, which will be easily oxidized at high temperatures or for a long time, which will cause yellowing and affect the use effect;

- The synthesis process of the two is different. Silicone microspheres have better particle size control, and the particle size distribution is narrower and more even;

XJY Silicones

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

We are manufacturing and customizing XJY-801 Polymethylsilsesquioxane(PMSQ) silicone microspheres in light diffuser material products, our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.

![]()