In the market today, converters and end users expect pressure-sensitive adhesives that do more than just stick under light pressure. Modern industrial applications require products that can meet strict environmental regulations, survive harsh temperatures, and still provide clean removability and long shelf life.

Silicone pressure-sensitive adhesives are a special type of psa that relies on silicones rather than acrylic or rubber polymers. They are designed to bond difficult substrates like low-energy plastics, while maintaining excellent adhesive strength, resistance to solvents, moisture, mildew, and fungus, and stable performance across a very wide operating temperature range.

- Why Silicone PSA instead of Organic PSA Systems?

- Inside a Silicone PSA – Silicone Polymer and Silicone Resin Working Together

- Comparing Silicone PSAs and Acrylic Pressure Sensitive Adhesive Technologies

- Cure Systems – How the Network is Built

- Why is silicone PSA friendly environment?

- Key Factors When Choosing a Silicone PSA System

- How to make silicone PSA perform better?

1. Why Silicone PSA instead of Organic PSA Systems?

When you compare silicone PSAs with more conventional acrylic pressure-sensitive adhesive or rubber-based systems, several key advantages explain why silicone PSAs are used in so many high-end applications:

Wide operating temperature range: from cryogenic conditions up to very high temperatures, where acrylics, foam, or rubber-based adhesives would fail.

Exceptional resistance to solvents, oils, chemicals, moisture, mildew, and fungus.

Reliable adhesion and bonding on low-energy surfaces such as fluoropolymers and polyolefins, where other pressure-sensitive adhesive technologies struggle.

Long shelf life and stable tack over time, even when coated as very thin films or in different thicknesses.

Because of this combination, silicone pressure-sensitive adhesive systems are used to manufacture:

High-temperature masking tapes and tape constructions

Electrical insulation tapes and assembly tapes for electronics

Plastic films, papers, and specialty film or foam backings for temporary protective or functional applications

Labels and graphic displays where clarity, adhesive performance, and clean removability are all required

In many of these situations, silicone PSAs are formulated to stick firmly under light pressure, withstand the application environment, and then be easily removed without residue once the job is done.

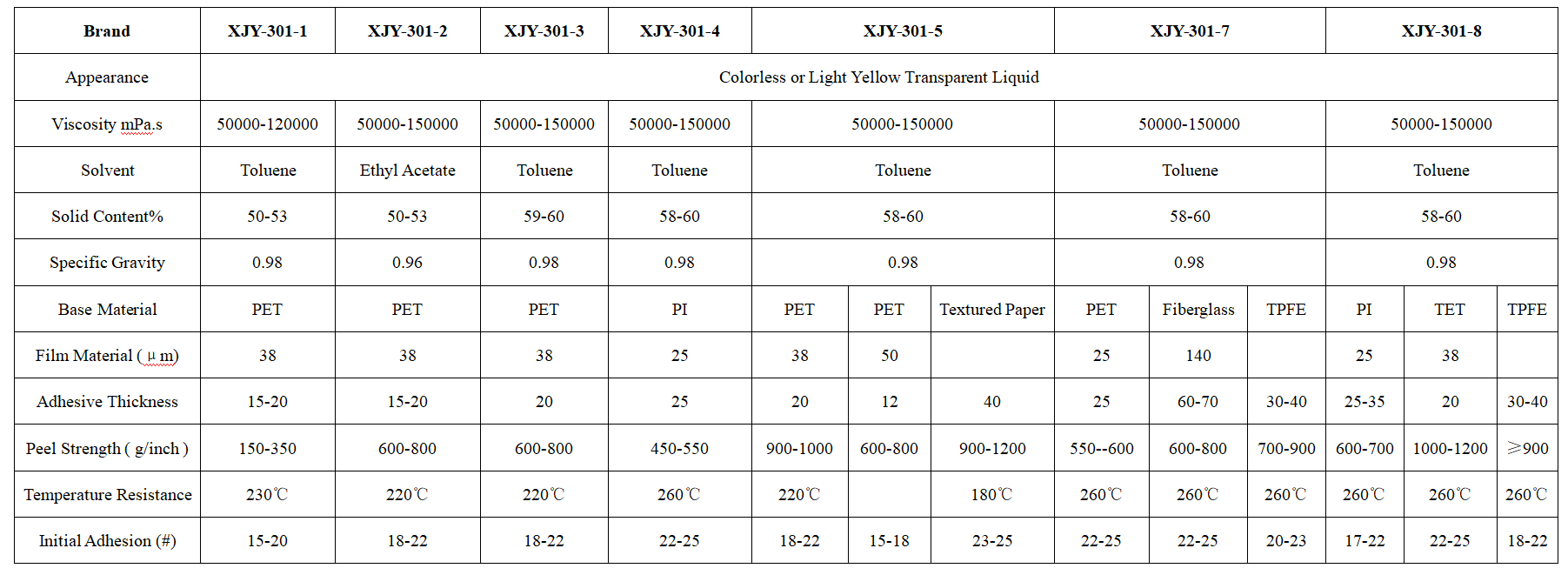

XJY-301 Silicone pressure-sensitive adhesives

It is made from the specific structure of silicone resin and high molecular weight polydimethylsiloxane in cooperation with organic adhesive, which is suitable for specific scene conditions.

Compared with natural rubber, it is characterized by heat resistance, high stability, good electric insulation, good transparency, high peel adhesion, and chemical resistance etc. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care, and mica tapes, splicing tapes, protective films, and other fields.

2. Inside a Silicone PSA – Silicone Polymer and Silicone Resin Working Together

Although the word “adhesive” sounds simple, a silicone PSA is actually a carefully engineered system. It is typically prepared as a blend of:

Siloxane Polymer (Silicone Gum)

- Provides flexibility, low-temperature performance, and base adhesive properties.

- Can be polydimethylsiloxane or methyl/phenyl copolymers.

MQ Silicone Resin (Tackifying Resin)

- Provides strength, cohesion, and high temperature resistance.

- Controls tack, peel, and shear via the resin/polymer combination.

These components are dispersed in a solvent such as toluene or an aliphatic medium, sometimes diluted for easier coating. By changing the resin-to-polymer ratio, the catalyst, and the crosslink density, formulators can achieve:

Different tack profiles for easy contact and bond build-up

Higher adhesive strength or higher cohesion for demanding assembly tapes

Better anchorage to different backings (polyimide, polyester, papers, cloth, plastic films, foam)

Improved high-temperature hold with clean removability

From the raw-material side, the focus is on designing silicone resins and silicone gums that offer the right balance of performance and processability so that converters can set their own formulations according to their application needs.

3. Comparing Silicone PSAs and Acrylic Pressure Sensitive Adhesive Technologies

In the market of pressure-sensitive adhesives, silicone and acrylic systems are often seen as complementary. Acrylic pressure-sensitive adhesive systems are widely used in general-purpose tapes, labels, and products where lower cost and good all-around performance are important.

However, when applications demand:

- Extreme temperatures

- Difficult substrates and low-energy surfaces

- High resistance to solvents, chemicals, sunlight, and outdoor exposure

- Very clean removability after long dwell times

Then, silicone pressure-sensitive adhesives are often the best choice. Silicone PSAs are typically formulated to provide higher thermal stability and better bonding to challenging surfaces, whereas acrylics may be limited by their glass transition temperature and chemical resistance.

In some cases, hybrid formulations have been developed that combine silicone and acrylic technologies, but pure silicone PSAs remain the benchmark where the most demanding factors must be satisfied.

4. Cure Systems – How the Network is Built

To turn a silicone PSA from a simple blend into a robust product, crosslinking is essential. Two main cure routes are common in the industry:

- Peroxide-Cured Silicone PSAs

- Use organic peroxides as a catalyst.

- Require multi-zone ovens: one zone for solvent evaporation and one for crosslinking.

Allow the converter to adjust strength, cohesion, and temperature resistance by changing peroxide level.

- Platinum Addition-Cured Silicone PSAs

- Use platinum addition cure chemistry between Si–H and vinyl groups.

- Can be prepared as solvent-borne or solvent-free systems.

- Often offer lower VOC, simpler oven design, and more flexible processing.

In both cases, the silicone resin and polymer are carefully formulated to react and set into a durable network that can bond well to the backing on one side and to the service surface on the other side.

5. Why is silicone PSA friendly environment?

Environmentally friendly silicone PSAs are not just a lab concept—many are already developed and commercialized to better meet modern environmental standards while maintaining the properties that users expect.

Electronics & Electrical

High-temperature masking tapes on polyimide or polyester films

Assembly tapes in electronics, where insulation, adhesive strength, and clean removability are essential

Protection and attachment products for displays and sensitive components

The silicone PSA layer is coated onto the backing and must retain anchorage, bonding strength, and insulation even after thermal cycling, moisture, and exposure to sunlight.

Masking tapes for paint shops, powder coating, and e-coat applications

Foam and rubber-based tapes, where silicone PSAs provide excellent adhesion and high-temperature performance

Temporary plastic films and papers that protect surfaces during fabrication and transport

Here, greener silicone PSAs can help reduce VOC emissions during manufacture, while still providing reliable bonds and easy removal when the protective film or tape is no longer required.

6. Key Factors When Choosing a Silicone PSA System

When choosing a silicone PSA or silicone pressure sensitive adhesive formulation, converters and brand owners should look at:

- Adhesive strength, tack, and peel on the final substrates

- High-temperature and low-temperature resistance

- Ability to improve anchorage to different backings and primers

- Required thicknesses and coat weight for the coating line

- Content of VOC and solvent, and whether a solvent-free path is desirable

- Specific applications in which the product will be used (electronics, automotive, construction, medical, etc.)

A well-engineered silicone PSA can provide a variety of performance results: strong bonds, easy removability, long shelf life, and reliable behaviour under environmental stress. Working with a silicone resin supplier that can assist with formulations and fine-tuning will help you discover the right balance for each application.

7. How to make silicone PSA perform better?

As a supplier of silicone resins for silicone PSAs and other adhesives, our focus is on helping customers develop or optimize:

- Resin and polymer combination for specific applications and backings

- Cure system (peroxide or platinum addition) to match your coating and oven setup

- Anchor-improving resins that help improve anchorage on film, paper, and foam backings

- Tailored formulations that can be diluted, coated, and cured efficiently while maintaining adhesive strength and clean removability

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone PSA field and support