RTV silicone rubber is a silicone rubber that can be vulcanized at room temperature. It has stable performance and can be stored for a long time. Bond with metal, electronic components or other materials, and protect the components after sealing.

How many kinds of RTV silicone rubber are?

RTV silicone rubber is generally divided into condensed silicone rubber and additional molded silicone rubber.

Additional type RTV silicone rubber is an elastomer that is based on linear polysiloxane with vinyl and hydrogen-containing siloxane as a cross-linking agent. In the presence of a catalyst, it is an elastomer that undergoes cross-linking reaction at room temperature to medium temperature. It has good heat resistance, wettability and electrical insulation. At the same time, due to the introduction of active end groups, it has excellent physical and mechanical properties, especially in terms of tensile strength, relative elongation and tears strength. It is suitable for radiation vulcanization, peroxide vulcanization, addition vulcanization and other vulcanization methods. It is widely used in heat-resistant, moisture-proof, electrical insulation and high-strength silicone rubber products.

Condensed RTV silicone rubber is characterized by the condensation reaction of silanol groups with other active substances, which can be cross-linked into elastomers at room temperature. Products are divided into single-component packaging and two-component packaging. One-component RTV silicone rubber (RTV-1 rubber for short) is one of the main products of condensed liquid silicone rubber. It is usually made of basic polymers, crosslinking agents, catalysts, fillers and additives. The product is packaged in a sealed hose and is extruded during use. It can be vulcanized into an elastic body by itself after contact with air, which is very convenient to use. Vulcanized rubber can be used for a long time in the temperature range (-60~200℃). It has excellent electrical insulation and chemical stability, water resistance, ozone resistance, weather resistance, and good adhesion to various metal and non-metal materials. It is mainly used for the coating of various electronic components and electrical equipment. The packaging material has the functions of insulation, moisture-proof and shock-proof; as a surface protection material for semiconductor devices; it can also be used as a sealing gap material and elastic adhesive.

Besides, there is another RTV silicone rubber--Two-component RTV silicone rubber (RTV-2 rubber for short), which is not as convenient to use as RTV-1 rubber, but its composition ratio is varied. A variety of vulcanized products with various specifications and performances can be obtained, and deep vulcanization can also be carried out. Therefore, it is widely used for insulation, encapsulation, caulking, sealing, moisture-proof, deep vulcanization, construction, textile, chemical industry, Light industry, printing and other industries. In addition, RTV-2 is also widely used as a soft mold material for imitating and manufacturing cultural relics, handicrafts, toys, electronic appliances, and mechanical parts.

What are the performance characteristics of RTV silicone rubber?

It has good adhesive properties and can be bonded with many materials without cracking. It has good electrical insulation and arc resistance, is moisture-proof and anti-vibration, it blocks the influence of the external environment on the components, and will not easily age. In addition, the adhesive is non-toxic, non-corrosive, has almost no pollution to the environment, and has a high environmental protection level.

RTV silicone rubber has good temperature resistance, as long as it does not exceed the temperature range of -60°C to 200°C, it can perform performance and protect components. The most powerful is the insulation and arc resistance, which reduces the possibility of accidents and improves the safety factor.

Which industries are RTV silicone rubber used in? What are the detailed applications of RTV silicone rubber?

One of the typical applications of silicone sealants made of RTV silicone rubber is glass curtain walls. The glass and aluminum alloy frame use organic silicon structural glue as the exterior wall material, and the expansion joint is waterproof and sealed with organic silicon weather-resistant glue. Other applications include the peripheral sealing of aluminum alloy doors and windows and plastic steel doors and windows, the joints of glass installations and movable grooves, the sealing of rivets and fixing screws: sanitary ware and countertops, walls, and kitchen and bathroom furniture, and toilets. Waterproof sealing between aquariums, ceilings, metal roofs, showcases, counters, wall panels, and color steel plates; used for waterproof caulking and sealing between high-grade road panels.

In addition to construction sealants, RTV silicone rubber also includes sealing materials used in aerospace, nuclear power plants, electronics, machinery, automobiles, and other industries, as well as silicone potting materials used for potting of electronic components and used as soft mold materials. Mold glue and so on. The demand for these varieties is relatively small, but they are indispensable on many occasions. At present, RTV silicone rubber is used in electronic components and electrical-related industries due to its excellent performance. It is widely used in the bonding and sealing of electronic components, semiconductor materials, electronic appliances and other equipment, the waterproofing and sealing of electric heaters and electronic instruments, and the potting of electronic components. Specifically, such as the sealing of electric heating ends, the bonding of small motor magnetic tiles and metal casings, the bonding and sealing of automobile lights, optical instruments and lenses, the bonding of electronic instrument casings, the insulation protection of motors, and the bonding and sealing of electronic components.

![]()

![]()

![]()

Among many synthetic rubbers, RTV silicone rubber is one of the best. It is tasteless, non-toxic, not afraid of high temperature, and resistant to severe cold. At 300 degrees Celsius and minus ninety degrees, the original strength and elasticity are not lost. RTV silicone rubber also has good electrical insulation, oxygen resistance, aging resistance, light resistance, mildew resistance, chemical stability, etc. Because of these excellent properties, RTV silicone rubber has been widely used in modern medicine. In recent years, through the cooperation of hospitals, scientific research units, and factories, a number of RTV silicone rubber medical products have been successfully trial-produced:

- RTV silicone rubber anti-noise earplugs: comfortable to wear, can block noise and protect the eardrum.

- RTV silicone rubber tire head suction device: easy to operate and safe to use. It can be deformed according to the size of the fetal head. The fetal scalp will not be sucked up during the suction process. It can avoid scalp hematoma and intracranial injury, and can greatly reduce dystocia during childbirth. pain of.

- RTV silicone rubber artificial blood vessel: It has special physiological functions and can be in close contact with the human body. "The human body will not reject it, and after a certain period of time, it will be completely stable with human tissues.

- RTV silicone rubber tympanic membrane repair sheet: thin and soft, with good finish and toughness. It is an ideal material for repairing eardrums. It is easy to operate and the effect is quite good.

- In addition, there are RTV silicone rubber artificial trachea, artificial lung, artificial bone, silicone rubber duodenal tube, etc., which are very effective.

With the progress and development of modern science and technology, the medical use of RTV silicone rubber will have broader prospects.

How to use RTV silicone rubber?

The operation method of RTV silicone rubber adhesive is very easy, clean the base surface dust, moisture, oil stains, etc. Apply glue to the part that needs to be sealed. Do not apply too much glue, just apply evenly. When it comes into contact with moisture in the air, it will begin to solidify from the surface to the inside. It takes about 24 hours to complete curing.

The curing requirement of RTV silicone rubber is not high, and it can be completely cured at room temperature. Before it is completely cured, do not move or touch, otherwise, it will affect the formation of the adhesive layer. After forming an elastic and hard adhesive layer, it can protect the components.

XJY Silicones

XJY-8206 and XJY-8206N series vinyl silicone resins and XJY-701 702 hydrogen-containing series products can be used as two-component RTV silicone resins.

- XJY-8206 series provide a hardened three-dimensional structure, VQM/VMQ resin series silicone products provide detailed solutions for electronic component assembly and industrial assembly of RTV silicone rubber.

| Brand | XJY-8206A | XJY-8206B | XJY-8206C | XJY-8206D | XJY-8206E | XJY-8206F |

| Product Name | Methyl VMQ Silicone Resin | |||||

| Appearance | White Powder | Colorless Transparent Liquid | ||||

| Molecular Weight | 2500-4000 | 2500-4000 | 4000-5000 | 2500-4000 |

|

|

| Vinyl Content | 1.8-2.2% | 2.4-2.9% | 2.4-2.9% | 4.0-4.5% | 0.5-0.8% | 0.8-1.2% |

| Brand | XJY-8206N-3 | XJY-8206N-5 | XJY-8206N-6 | XJY-8206N-7 | XJY-8206N-8 | XJY-8206N-9 | XJY-8206N-10 |

| Product Name | Methyl VMQ Silicone Resin + Vinyl Silicone Oil Polydimethylsiloxane | ||||||

| Appearance | Colorless Transparent Liquid | ||||||

| Viscosity (25℃, mm2/s) | 10000 -15000 | 9000 -13000 | 42000 -65000 | 10000 -20000 | 12000 -20000 | 10000 -20000 | 85000 -115000 |

| Vinyl Content | >1.23-1.3% | >1.65-1.8% | >1.40% | >0.7-0.9% | >1.2-1.3% | >0.3-0.6% | >1.2-1.3% |

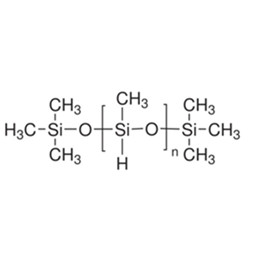

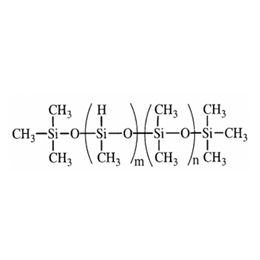

- XJY-701(Polymethylhydrosiloxane) and XJY-702(Methylhydrosiloxane, Dimethylsiloxane Copolymer) hydrogen-containing silicone oil series are used as the main body of crosslinking agents and vinyl silicone oil.

| Product Name | Hydrogen content(%) | Viscosity (25℃,mm2/s) | Reflective Index(n25d) | Density (25℃,g/cm3) | Volatile (105℃/3h) |

| XJY-701 Polymethylhydrosiloxane | 1.58-1.62% | 15-30 | 1.390-1.410 | 0.995-1.015 | ≤1% |

| Brand | 702B-18 | 702B-36 | 702B-50 | 702B-75 | 702B-100 |

| Appearance | colorless clear liquid | ||||

| Hydrogen Content (%) | 0.18±0.02% | 0.36±0.02% | 0.50±0.02% | 0.75±0.02% | 1.00±0.02% |

| Viscosity (25℃, mm2/s) | 140-180 | 90-130 | 90-130 | 90-130 | 40-60 |

| Volatile (105℃/3h) | ≤2% | ||||

| Refractive Index( | 1.390~1.410 | ||||

| Density (25℃, g/cm3) | 0.98~1.10 | ||||

Choosing the right product mainly depends on the customer's manufacturing process, operating requirements, curing conditions, equipment and material performance requirements. ents.

XJY Silicones as one of the leading silicone manufacturers is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry. Our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.