The silicone rubber development market has shown steady growth in recent years. As a globally important industrial material, silicone rubbers are widely used in a number of fields due to their excellent resistance to high temperature, low temperature, aging, insulation, and environmental protection. In the future, with the development of science and technology and industrial upgrading, the application areas of silicone rubber will be further expanded, and the market demand will be more vigorous. What kinds of silicone rubber?

Silicone rubber is the largest number of silicone versatile material in a class, by a variety of dichlorosilane through hydrolysis, polycondensation, and an element of organic elastomers. It can be divided into heat vulcanization type (high-temperature vulcanization silicone HTV), and room temperature vulcanization type (RTV), of which the room temperature vulcanization type is divided into polycondensation reaction type and addition reaction type. High-temperature silicone rubber is mainly used in the manufacture of a variety of silicone rubber products, while room-temperature silicone rubber is mainly used as an adhesive, potting material, or mold. The largest amount of hot vulcanized type, hot vulcanized type and sub-methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, the amount and the most popular product brands), methyl vinyl phenyl silicone rubber PVMQ (low temperature, radiation resistance), and other fluoro-silicone rubber, and so on.

The following three aspects of silicone rubber and its applications:

- What is silicone rubber?

- Additional molding liquid silicone rubber

- HTV high-temperature vulcanized silicone rubber

- How is silicone rubber applied?

- How to make silicone rubber perform better?

1. What is silicone rubber?

Silicone rubber, its main chain of the molecule is -Si-O-bond, with monovalent organic groups as the side group of the linear polymer, according to the vulcanization temperature is divided into two categories of high-temperature and room temperature vulcanization of silicone rubber, the first molecular weight of more than 100X104 solid rubber, the latter for the molecular weight of 1X104 ~ 5X104 viscous liquids. Si-O bonding energy (370kJ/mol) is much higher than C-C bonding energy (240kJ/mol), and the molecular chain is smooth, so it has excellent high and low-temperature resistance, and the use temperature is -70~300℃; meanwhile, it has excellent electric insulation performance, and it has no toxicity to the human body organization. It is suitable for high-temperature seals of air systems, insulating parts, profiles, hose diaphragms, and medical and health products.

2. What are the characteristics of silicone rubber?

(1)High and low temperature resistance

Among all rubbers, silicone rubber has the widest range of operating temperatures (-100~350℃). For example, after appropriate coordination of vinyl silicone rubber or low-phenyl silicone rubber, 250 ℃ thousand hours or 300 ℃ hundred hours of hot air aging can still maintain the elasticity; low-phenyl silicone rubber vulcanized rubber by 350 ℃ dozen hours of hot air aging can still maintain the elasticity of its glass transition temperature of -140 ℃, its vulcanized rubber in the -70 ~ 100 ℃ temperature still has the elasticity. Silicone rubber used for rocket nozzle wall heat coating can withstand instantaneous high temperatures of thousands of degrees.

(2) Ozone aging, oxygen aging, light aging, and weather aging resistance performance

Silicone rubber vulcanized rubber in the free state in outdoor exposure for several years, with no significant change in performance.

(3) Electrical insulation properties

Silicone rubber vulcanized rubber electrical insulation properties in the moisture, frequency changes, or temperature rise when the change is small, the silica generated after combustion is still an insulator. In addition, the molecular structure of silicone rubber has fewer carbon atoms and does not use carbon black as filler, so it is not easy to scorch in the arc discharge, and in high-pressure occasions is very reliable. Its corona resistance and arc resistance are excellent, corona resistance life is 1000 times that of PTFE, and arc resistance life is 20 times that of fluoroelastomer.

(4) Special surface properties and physiological inertia

Silicone rubber surface energy is smaller than most organic materials, has a low hygroscopicity, long-term immersion in water absorption rate of only 1% or so, the physical properties do not decline, good mildew resistance and many materials do not occur adhesion, can play a role in isolation. Silicone rubber is odorless, non-toxic, has no adverse effects on the human body, and the body tissue reaction is slight, with excellent physiological inertia and physiological aging.

Silicone rubber and other polymer materials, compared with good permeability, room temperature on nitrogen, oxygen, and air through the amount of 30 to 40 times higher than the NR; gas permeability with selectivity, such as carbon dioxide permeability for oxygen about 5 times.

(6) Biomedical properties

The characteristics of the molecular structure of silicone rubber make it have excellent biomedical properties, a large number of animal and human test successes proved this.

3. How to compare silicone rubber with ordinary rubber?

The main difference between silicone rubber and ordinary rubber lies in their chemical structure, performance characteristics, and application areas.

(1) Chemical structure:

The main chain of silicone rubber consists of alternating silicon and oxygen atoms, silicon atoms are usually connected to two organic groups. Ordinary silicone rubber is mainly composed of silicone oxygen chain links containing methyl and a small amount of vinyl. This structure gives silicone rubber its unique properties.

Ordinary rubber is a highly elastic polymer material, with reversible deformation characteristics, elastic at room temperature, and able to produce a large deformation under the action of a small external force, remove the external force can be restored to its original state.

(2) Performance characteristics:

Silicone rubber has excellent high and low-temperature resistance, good low-temperature resistance, generally still works at -55 ℃, after the introduction of phenyl up to -73 ℃; heat resistance is also outstanding, in the 180 ℃ for long-term work, instantaneous resistance to high temperatures of more than 300 ℃. In addition, silicone rubber is also physiologically inert and does not lead to blood clotting, so it is also widely used in the medical field.

Ordinary rubber is characterized by good elasticity, high strength, and good overall performance, but in contrast, silicone rubber is superior in high and low-temperature resistance.

Silicone rubber, due to its unique properties, is widely used in medicine, electronics, construction, and many other fields, such as medical products, electronic components encapsulation, building seals, and so on.

Ordinary rubber is mainly used in the production of hoses, rubber rollers, and other industrial products.

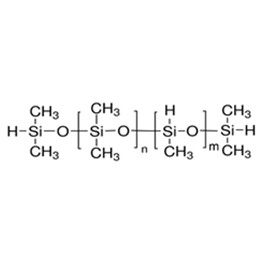

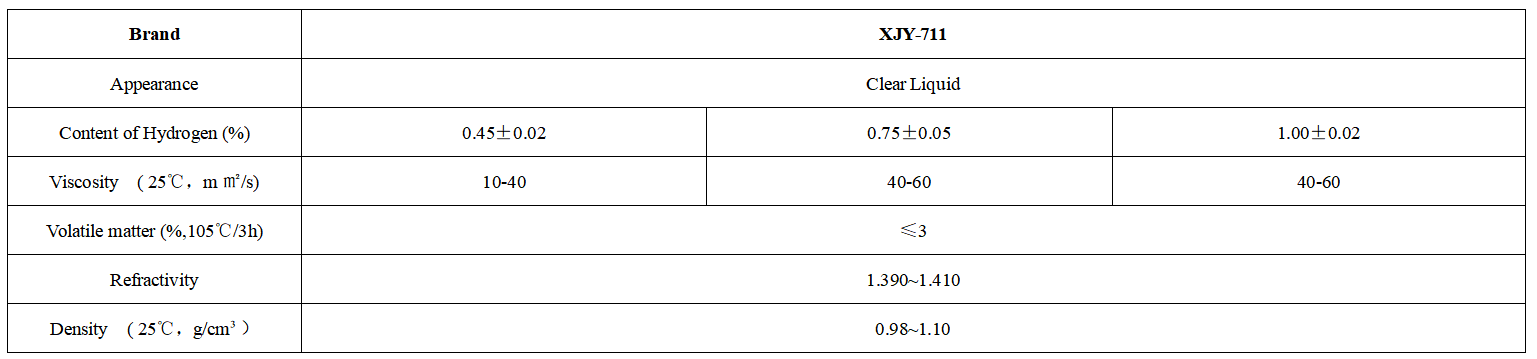

XJY-711 Hydrogen-terminated methylhydrosiloxane/dimethylsiloxane copolymer

It is a colorless transparent liquid, which can be used as crosslinking agent of silicone rubber.

4. Additional molding liquid silicone rubber

LTV is a kind of LIMS liquid injection molding silicone rubber of LSR. The composition and vulcanization of additive molding liquid silicone rubber-LTV consists of vinyl silicone oil, hydrogen-containing silicone oil, platinum catalyst, reinforcing filler, and additives.

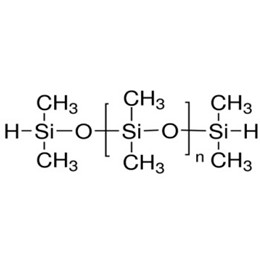

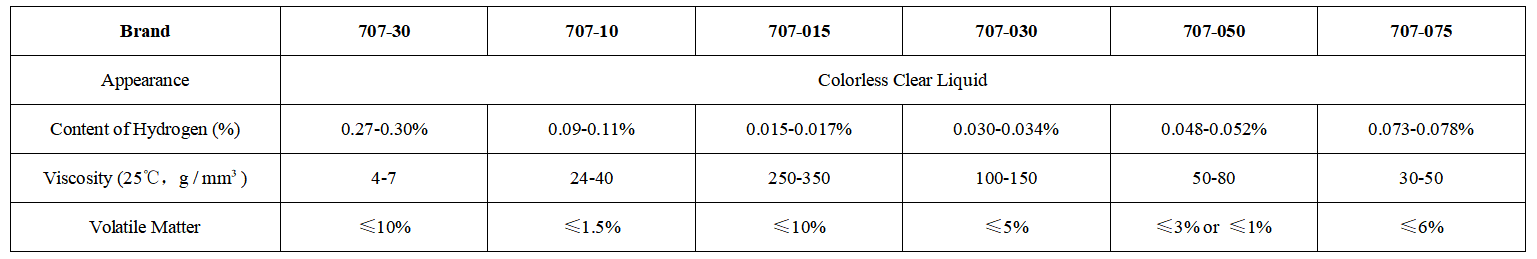

XJY-707 Hydride terminated Polydimethylsiloxane

It can be synthesized through the silicone-hydrogen addition reaction of copolymer polymers due to the molecular structure containing active hydrogen atoms and can be made into a series of active silicone oils. It can be used as a chain extender for liquid silicone rubber.

XJY-711 Hydrogen Terminated Methylhydrogensiloxane /Dimethylsiloxane Copolymer

It is a colorless transparent liquid, that can be applied as a crosslinking agent of silicone rubber.

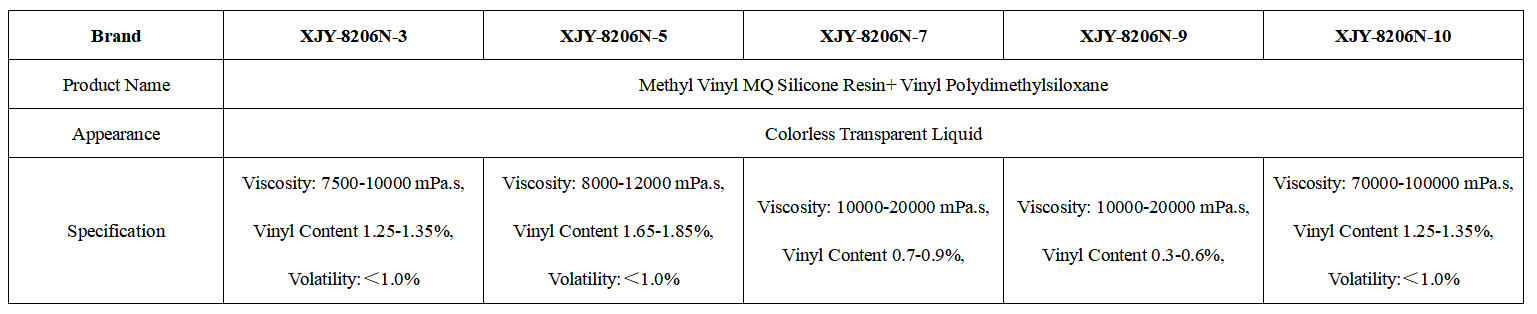

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Polydimethylsiloxane

It is a colorless transparent liquid resin with methyl and vinyl consisting of vinyl MQ silicone resin and vinyl silicone oil, which can be used for LSR liquid additive molding silicone rubber.

Vulcanization mechanism

(1)Because organic nitrogen, phosphorus, sulfur, and tin will make the catalyst Pt poisoning, affecting the vulcanization, the vulcanization test should be carried out before use.

(2)Neoprene and other synthetic rubbers, sulfur-containing compounds, soft PVC, amine-cured epoxy resin, PVC insulating tapes, turpentine fluxes and so on will hinder the curing, and they can not be used at the same time.

(3)Moisture and humidity will also affect the vulcanization, please store in a dry place.

(2) Applications of LTV

- Low-strength type is mainly used for coating semiconductor electronic components, and potting materials (with shell), to achieve insulation, moisture, dust, and shock, and improve the performance of the purpose of stabilizing parameters, but it also can be formulated with a variety of paper isolation agent.

- It is a high-strength type with good mechanical properties, and it can be used as electronic components without shell encapsulation materials.

- Good adhesion can be used as semiconductor devices within the protective coating, and mixed with silver powder can be used as a bonding conductive adhesive.

- Aviation-type highly transparent materials can make bulletproof glass and aviation bonding agents.

- The medical types used in plastic surgery, saddle nose orthopedics, and atrophic rhinitis treatment; are beauty; and artificial lenses.

- Filled type for flame retardant potting adhesives, foam adhesives, anticorrosive adhesives, coatings, and inks.

- Liquid injection molding-LIMS buttons, pacifiers, etc.

- One-component adhesives, coatings, and inks.

5. HTV high-temperature vulcanized silicone rubber

Due to the poor mechanical properties of HTV raw rubber, it is necessary to add the following components: reinforcing agent: silica; structure control agent; filler; coloring agent: a variety of pigments to do the color paste; a variety of additives; vulcanizing agent: peroxide or addition vulcanization.

Si atom is larger than the C atom, -Si-O-Si- is a spiral structure, the organic group outward, so that the intermolecular force is small, the vulcanized rubber strength is very low, must be added filler reinforcement, otherwise it can not be used.

(1) Electrical properties

Silicone rubber has excellent electrical insulation volume resistance: 101414 ~ 1016Ω.m, in a wide range of temperatures and frequencies in the field, it can maintain stable electrical properties. In addition, even if it is immersed in water, its electrical insulation properties will not decline; therefore, it is most suitable for insulating materials.

(2) Thermal conductivity

Silicone's thermal conductivity than the general coefficient of organic rubber, silicone rubber in the addition of a large number of inorganic fillers can improve the thermal conductivity of silicone rubber, making it work at extreme temperatures these materials can be used in heat sinks and heating rollers.

(3) Steam resistance

Even if immersed in water for a long time, the water absorption of silicone rubber is only 1%; and the mechanical strength and electrical properties will not be affected by almost any (whether cold water, warm water, boiling water, almost no change). However, in the 150 ℃ high-pressure steam environment, the silicone will degrade, and the performance will decline. By improving the formula, selecting the vulcanizing agent, extending the time of the second addition of sulfur, and other measures to improve the steam resistance, but also to develop products with particularly high resistance to steam, and hot water resistance.

(4) Oil, solvent, and chemical resistance

The oil resistance of silicone rubber in a 100℃ environment is slightly worse than that of nitrile rubber and neoprene rubber. At >100℃, silicone rubber is able to exert more excellent oil resistance. Silicone rubber is hardly eroded by polar solvents and weak acids and alkalis, but it will be dissolved in non-polar solvents, but not dissolved, and can be restored to its original state by removing the solvents. Silicone rubber is not resistant to strong acids and alkalis. Solvent chemicals on the silicone rubber to produce swelling, softening, strength loss, and other phenomena, different types of solvents on the impact of silicone rubber is not the same. It can be used for medical devices and making molds.

(5) Compression permanent deformation

Organic rubber at room temperature in the compression permanent deformation is small, but with the temperature change will increase significantly. Silicone rubber in -60 ~ 250 ℃ within the compression permanent deformation is stable, that is to say, silicone rubber in the very temperature used than organic rubber is good. Bending fatigue: silicone rubber bending fatigue resistance is not better than organic rubber. Measures must be taken to develop 8 ~ 10 times the fatigue resistance of the species, it can be used in keyboards and conveyor parts. Strength: at room temperature, the strength of silicone rubber is lower than organic rubber, but at high temperatures, the strength of the retention rate is higher, and the strength is better than organic rubber. Silicone rubber tear strength is low, only to improve the synthesis of the base rubber process as well as mixing rubber filler, the crosslinking agent can be prepared to tear strength of 30 ~ 50 kN / m of the high-strength type of products, suitable for reverse cone molds and large molding products forming materials used.

6. How is silicone rubber applied?

Room temperature vulcanized silicone rubber is mainly used in the production of aircraft cockpit, fuselage, and overall fuel tank sealant and construction of waterproof, leak-proof sealing materials. Methyl vinyl silicone rubber than dimethyl silicone rubber using a wide range of temperatures, good strength, compression permanent deformation is small; phenyl silicone rubber low-temperature performance is better, in a 100 ℃ still have elasticity, and has higher heat resistance, amplitude of light resistance; fluoro-silicone rubber both fluoroelastomers and the advantages of silicone rubber, can resist mineral oil and chemical solvents.

(1)Automobile industry

Silicone rubber in the automotive industry the application of rapid growth, silicone rubber (especially with a variety of characteristics of silicone rubber) can be resistant to fuel, and lubricant erosion, improve the performance of automotive components, and reduce maintenance costs. Can be used for automotive ignition wires, spark plug protection covers, heating and radiator hoses, muffler lining, and battery connectors, as well as with fluoro silicone rubber made for gasoline pumps and so on. With the development of electronic electrification of vehicles, room temperature vulcanization of silicone rubber is widely used in electronic parts, electrical fittings, potting material, windshields, sealing around the body and mirrors, and another adhesive sealant.

(2) Electronics, electrical industry

The electronics and electrical industry is the earliest use of silicone rubber as an insulating material, a larger demand for the field. Silicone rubber is mainly used for television anode covers, high-voltage protective covers, high-voltage lead wires, refrigerator defroster wires, and power or signal transmission with wires and cables. Insulators made of silicone rubber will replace ceramic products that are widely used in transmission lines, especially ultra-high voltage lines. Conductive silicone rubber for electronic computers, telephones, and other instruments of the electrical contacts and liquid crystal display contacts. Flame-retardant and radiation-resistant silicone rubber wires and cables are widely used in atomic power stations. Silicone rubber heating pads and heating tape are used to control a variety of precision instruments and oil pipeline operating temperatures, in the medical treatment for physical therapy hot compresses with a heating blanket. Room-temperature vulcanized silicone rubber can be used as waterproof, moisture-proof, and shockproof potting materials.

Silicone rubber has been widely used in dishwashers and washing machines for pump seals because of its resistance to hot washing liquids. Silicone rubber is well suited for gaskets on appliances such as coffee pots, electric fryers, and steam irons. The stereo headphones' ear and head cushions were changed to silicone rubber, which can exclude outside noise, and is soft and comfortable.

(3) Aerospace industry

Silicone rubber is indispensable to the aerospace industry, a high-performance material, it can withstand ultra-cold space and return to the atmosphere of the burning heat, extend the life of aircraft parts, reduce maintenance costs, and reduce accidents. Mainly used in aircraft body cavity seals, electrical connectors, sealing switches, dust and waterproof cover, gaskets, gaskets, jet engines, hydraulic devices, “O” sealing rings, oxygen masks, control diaphragms, hot air ducts, radar wireless shock absorbers. Scorch-resistant silicone rubber is used for rocket fuel valves, power source cables, and rocket silo cover coatings to avoid being scorched by the rocket jet stream. Room temperature vulcanization of silicone rubber can be used as airtight sealing of the body, window sealing, and shockproof, moisture-proof potting materials.

(4) construction industry

Silicone rubber has good weather resistance and construction, as an adhesive sealant in the construction industry has been widely used, more than other types of sealants. In recent years, and the development of a low modulus high elongation two-component sealant, which is used for joints moving large precast concrete parts and curtain walls and other large components. Room temperature vulcanized silicone rubber is also used for asbestos cement board joint sealing, bathroom tile joints and toiletries sealing. With the future decline in the price of rubber, will further expand the scope of application, such as in the application of highway joints to replace asphalt and neoprene. High-temperature vulcanization of silicone rubber sponge strip used as a building door and window sealing inserts.

(5) medical field

Silicone rubber has good biocompatibility, small reaction to the body, stable performance, low blood coagulation, can withstand high temperatures and high pressures many times cooking, and can be processed into a variety of shapes of products, such as films, sponges, airbags, is currently the most widely used in the medical application of a material.

In addition to the above applications, silicone rubber in textile, printing, machinery, plastics, chemicals, paper food and make-up, and other areas of application has increased significantly. Typical products are made of silicone rubber rollers, used as fabrics, plastics, heat-setting, embossing, calendering, and photocopier fixing. Silicone rubber film made of air-conditioned windows has been used to store fruit and vegetables. In addition, silicone rubber in textile high-temperature equipment, as well as in the alkali, sodium hypochlorite, and hydrogen peroxide concentration of equipment for sealing materials also achieved good results

7. How to make silicone rubber perform better?

The characteristics of silicone elastomers rubber are silicone (polydimethylsiloxane) molecular structure to siloxane bond-based is a very stable structure, so compared with ordinary organic rubbers, silicone compounds have many beneficial properties, such as temperature resistance(low temperatures, electrical insulation, chemical stability. In addition, because the methyl group on the outside of the helical structure can rotate freely, silicones are able to exhibit many unique surface properties, such as water resistance and mold release. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support to produce silicones. Our silicone raw material products can meet the needs of the silicone rubber field and support the provision of diversified silicone products and customized solutions.