With the development of modern medical electronic products and the improvement of medical level, people's health care awareness has gradually increased, a variety of health care physical therapy devices also continue to appear, and the application of electrode plates is more and more extensive, so the application of silicone rubber in the field of medical electrode plate has a huge potential and the prospect. Why choose silicone rubber for medical electrode plates?

As the electrode plate is a component in contact with the human body, the rubber material is required to be soft, comfortable, present physiological inertia, non-toxic to the human body, non-irritating to the skin, and breathability. In the process of use, it should be able to withstand many times of high temperature and pressure, medical alcohol, or potassium permanganate solution sterilization without affecting the performance.

As the one of main types of silicone polymers, silicone rubber is adapted to these requirements and is extremely suitable as a base material. In synthetic rubber, silicone rubber is a polymer with siloxane Si-O structure as the main chain, with excellent heat resistance, aging resistance, weather resistance, high tear, and ozone resistance, there is good resistance to compression permanent deformation properties in a wide range of temperatures, but also has physiological inertia, so conductive silicone rubbers not only can maintain the characteristics of the silicone rubbers itself but also is conductive in the medical device. The electronic and electrical field has the largest amount of conductive rubber and is the first choice of conductive rubber substrate.

Here is some information about it:

- What is silicone rubber?

- How to classify silicone rubbers?

- What are the properties of silicone rubber?

- What is the role of conductive fillers?

- What is the mechanism of conductive rubber?

- What affects the conductivity of an electrode plate?

- How to apply silicone rubbers?

- How to make silicone rubbers?

1. What is silicone rubber?

Silicone rubber is a polymer elastomer with a combination of inorganic and organic properties, it's the main chain of molecules is composed of the alternation of silicon atoms and oxygen atoms (Si-O-Si), and silicon-oxygen bonding bonding energy can be up to 370KJ/mol more than the general carbon-carbon bonding (240KJ/mol), which is one of the main reasons for the pure silicone rubber has a very high thermal stability.

Its side chain is CH connected with the silicon atom or CH organic groups substituted, the earliest such group is methyl, and in order to improve the vulcanization activity of the rubber and other modifications, gradually develops to introduce a very small amount of unsaturated vinyl or other organic substituent groups in the side chain. This low unsaturation of the molecular structure of the silicone rubber has excellent resistance to heat aging and weather aging and is very effective against ultraviolet light and ozone.

Siloxane chain is a spiral structure, and the flexibility of the molecular chain, and the intermolecular interaction force is weak, these characteristics make its vulcanized rubber soft and elastic, but physical and mechanical property is poor. When the temperature changes, the intermolecular forces change very little so its property, especially the elasticity of the change is not great.

Compared with general common organic rubbers, the formula of three categories of silicone rubber with the components is relatively simple, hot vulcanization type is also the case. In addition to the raw rubber, the compounding agent mainly includes reinforcing agent, vulcanizing agent, and some special additives, generally only need to have 5 to 6 components that can be composed of practical formulations.

2. How to classify silicone rubbers?

There are many ways to classify silicone rubber, usually according to the forms of silicone before curing is divided into solid silicone rubber and liquid silicone rubber (LSR).

According to the vulcanization temperature, silicone rubber is divided into heat vulcanization type high-temperature vulcanized silicone (HTV), and room temperature vulcanization type (RTV). The hot vulcanized type has the largest amount, the hot vulcanized type is divided into methyl silicone rubber (MQ), methyl and vinyl groups silicone rubber (VMQ), and so on.

(1) High-temperature vulcanized silicone rubber

High-temperature vulcanized silicone rubber is a high molar mass of linear polydimethyl (or Methyl Vinyl, Methyl Phenyl Vinyl, Methyl Trifluoropropyl, etc.) siloxane as the basic polymer, mixed with reinforcing fillers and vulcanizing agents (silicone oxides), etc., vulcanization under pressure into an elastomer in the heating.

(2) Room-temperature vulcanized silicone rubber

Room temperature vulcanized silicone rubber (RTV) is a new type of silicone elastomer introduced in the 60s, the most notable feature of this rubber is that it can be pressured to cure on the spot at room temperature without heating, is extremely convenient to use. According to its vulcanization mechanism, it can be divided into condensation and addition molding; according to its packaging, it can be divided into two-component and one-component two types.

Now room temperature-vulcanized silicone rubber has been widely used as silicone adhesives, silicone sealants, silicone protective coatings, potting, and molding materials, widely used in all walks of life. Room temperature vulcanized silicone rubber (RTV) carries one or two functional groups at each end (and sometimes in the middle) of the molecular chain, and under certain conditions (moisture in the air or appropriate catalysts), these functional groups can react to form a high molecular weight cross-linked structure.

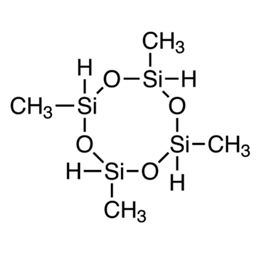

XJY-705 1,3,5,7-Tetramethylcyclotetrasiloxane(D4H)

It is a reactive siloxane with Si-H bonds, which can undergo additional change with unsaturated olefin and can be used for the synthesis of room-temperature vulcanized silicone rubber.

3. What are the properties of silicone rubber?

Silicone rubber is the most basic base material for electrode plates. Among various materials, silicone rubber has replaced other rubbers as the most commonly used rubber for medical electrodes because of its excellent performance.

Silicone rubber is a special synthetic rubber, which is made of Dimethylsiloxane monomer and other silicone monomers, polymerized under the action of a suitable catalyst and become a linear polymer, after mixing, and vulcanization can be crosslinked with each other into a rubber elastomer.

The characteristics of silicone rubber are manifested in the following aspects:

(1) Excellent high and low-temperature resistance;

It has good high-temperature resistance and can be used continuously at 180-200 ℃. Although the strength of silicone rubber is only half of natural rubber or some synthetic rubber at room temperature, silicone rubber can still maintain a certain degree of flexibility, resilience, and surface hardness, and the mechanical properties do not have significant changes in the high-temperature environment of more than 200 ℃,

(2) Special surface property and physiological inertia;

Silicone rubber surface energy is lower than most organic materials, so it has excellent hydrophobicity and hydrophobic migration, low hygroscopicity, and good mildew resistance; silicone rubber is non-obscurant, non-toxic, has no adverse effects on the human body, and the body tissue reaction is slight, with excellent physiological inertia and physiological aging.

(3) Breathability;

Compared with other polymer materials, highly permeable silicone rubber has extremely superior permeability at room temperature to nitrogen, oxygen, and air permeability than natural rubber 30 - 40 times higher.

(4) Recyclable;

Uncontaminated silicone rubber can be silicone rubbers recyclable, it's convenient to reuse silicone rubber products.

(5) Excellent insulation properties;

It has stable dielectric properties over a wide range of temperatures and frequencies and very good arc resistance and leakage resistance;

(6) Good elasticity, low-temperature flexibility

It can be used at -50 ℃. The glass transition temperature of silicone rubber is generally -70~-50℃, and the special formula can reach -100℃, indicating its excellent low-temperature performance;

(7) Good flame retardant properties, when burning, almost no release of toxic and harmful gases;

(8) Excellent weathering properties and chemical resistance to UV, salt spray, etc..

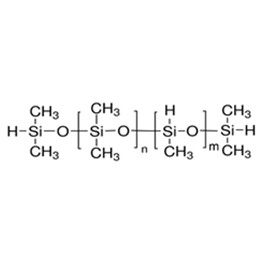

711-Hydride Methylhydrosiloxane Dimethylsiloxane Copolymer

It is a colorless transparent liquid that can be used as a crosslinking agent for the application of silicone rubber.

4. What is the role of conductive fillers?

Conductive fillers are the main substances that make insulating rubber electrically conductive. Among many conductive materials, carbon black is the first conductive material used, among which acetylene carbon black is more famous. It is obtained by high-temperature thermal decomposition of acetylene gas, referred to as acetylene black. Acetylene carbon black has high conductivity, compared with metal powder, it has a certain reinforcing effect on rubber, superior processing performance, small resistance to rubber vulcanization, and good heat resistance. Acetylene carbon black is electrically conductive due to its high structural in aggregate state structure of carbon black, acetylene carbon black has the highest aggregate state, and furnace carbon black is higher than slot carbon black. High-structured carbon black particle chains and networks can form conductive complexes, while low-structured carbon black lacks particle chains, and conductivity is poor.

5. What is the mechanism of conductive rubber?

The conductive mechanism of conductive rubber depends on the conductive material used. Carbon conductive filler, such as graphite, carbon black, etc., is through its own π electron migration and the formation of electric current in the polymer; metal filler is itself in contact with each other so that the free electrons move and generate electric current. There are several theories about the conductive mechanism of carbon conductive polymers, including the conductive pathway and tunneling effect theory. It is now generally recognized that "electron tunneling" that is, the tunnel effect is the principle of conductive generation. The applied voltage creates an electric field between carbon black particles that are adjacent and spaced by a thin layer of polymer, allowing electrons to pass through The resulting current depends on the path the electrons cross between the two conductive particles.

6. What affects the conductivity of an electrode plate?

The role of the conductive filler in conductive rubber is indispensable, so the properties of the conductive filler and its content in the rubber, the molecular weight of the rubber, the degree of cross-linking and other fillers, and the operating process conditions all have an effect on the final conductivity.

6.1 Why conductive filler is decisive?

The filling of the conductive filler is most decisive for the conductivity of the rubber. The conductivity of silicone rubber mixed with carbon black depends on the amount of filler added. The growth rate of the conductivity of conductive polymers is small with increasing filler volume but increases exponentially when the filler volume exceeds a certain percentage (i.e., the permeability limit). Acetylene carbon black with a high degree of structure and small particle size can give rubber high conductivity and mechanical properties. This is because when the particle size is small and the structure is high, the carbon black is easy to form a continuous structure and is conductive under certain conditions of ratios.

The shear strength of the conductive silicone rubber material depends on the proportion of carbon black, shear strength, and polymer viscosity. The conductivity of the final product has a similar relationship with the processing performance, but it is more difficult to distinguish the relevant role of various parameters. The processing properties of conductive silicone rubber materials as well as the viscosity and curing properties can be adjusted within a certain range according to the user's needs.

Different vulcanization methods also have an impact on the conductivity of the rubber. In carbon black-filled silicone rubber, with additional vulcanization, peroxide vulcanization, radiation vulcanization, and polymerization filling methods, will cause the final conductive properties of different, the vulcanized rubber made by the polymer filling method has the highest conductivity. This is because filler particles can reach the maximum dispersion in the polymer when using this method.

7. How to apply silicone rubbers?

All kinds of medical electronic instruments must act on a part of the body through the electrode surface, such as physical therapy instruments therapeutic instruments, cervical spondylosis, frozen shoulder, lumbar and leg disease arthritis soft tissue injuries, and other conditions that have a good auxiliary therapeutic effect. It will be low-frequency pulse and meridian, nerve theory, using skin electrodes on the human body acupuncture points for current stimulation, to activate the meridian function, soothe the pain, eliminate nerve paralysis, as well as the treatment of disease purposes. Early physical therapy instrument electrode is mainly used in the form of metal copper sheet outsourcing flannel, due to the metal material in contact with the human body is easy to rust, and can not be changed with the change of body parts and arbitrary change of shape, the use of extremely inconvenient, with silicone rubber products for electrode plate, can be shown unexpected results.

The most basic constituent materials of medical electronic plates are silicone rubber substrates to meet the requirements of medical materials and the actual use of the requirements and conductive filler make it have good conductive properties, it can have better performance if matched with other auxiliary components.

8. How to make silicone rubbers?

Silicone rubber is a comprehensive performance synthetic rubber, with excellent thermal stability; and high and low-temperature resistance; it can work long term in the -60 ℃ ~ 250 ℃ state; ozone resistance; weather resistance, and good electrical properties, corona resistance, electric arc; the electric spark is very strong; chemical stability, weather aging resistance, radiation resistance, physiological inertia, breathability, high tear. It can be widely used in the field of medical devices. How to make your products more competitive?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our hydrogen silicone products can meet the needs of silicone medical devices and support the provision of diversified customized solutions.