水汽对建筑物的危害常常会造成防水层与基层剥离、防水层鼓包、搭接缝开裂等现象,导致防水层的使用寿命大大降低。这时就需要喷涂有机硅防水材料来保护建筑物,为什么选择它呢?

特殊配方的有机硅防水剂,具有优异的憎水、防污、耐候、耐久性,可最大程度地提高建筑物的防水性能,是一种具有良好应用前景的新型刚性防水材料。它既可以水溶液或乳液形式喷涂于建筑物表面,也可以粉状形式直接掺入水泥砂浆或混凝土中作为防水剂。有机硅防水剂与水泥发生化学键合,形成牢固的整体刚性防水层,提高砂浆和混凝土的耐磨性和耐久性。

1、建筑漏水的危害有哪些?

The hazards of water vapor on the building require that the building be waterproof and breathable at the same time. Black roofs can reach a maximum temperature of 85 ℃ in summer. Under the 85℃ sealing condition, water will generate 1.46x108Pa (1445 atmospheres) pressure to the surrounding buildings. As the building is composed of silicate and other inorganic materials, these materials are porous, and permeable, and can greatly attenuate the water vapor travel added to the building on the pressure, but the pressure generated by the water vapor on the building is still very serious, especially in some buildings with poor permeability, this harm is very obvious.

![]()

(1) Water leakage will reduce the durability and safety of the building's engineering structure because there are voids and cracks in the cement products, masonry blocks, and mortar. When the water comes in, if the temperature drops below freezing, then the water ice, the volume of its expansion of about 90%, it will be directly extruded material, resulting in the surface of the material peeling: at the same time squeezing the remaining water inside, so that the material inside also produced stress, thus triggering cracks have further expansion.

(2) The larger the porosity of the material, the more cracks, the larger the water content, and the greater the environmental humidity, the situation is more serious. As the service life increases, this situation is also more and more serious, resulting in the material bond cross-section continuing to reduce cracks continuing to increase, and the bearing capacity of the material also continuing to decline.

(3) The destruction of the protective layer of concrete will also lead to the corrosion of steel bars, and the effective cross-section of steel bars will also continue to decrease; in addition to the corrosion of steel bars, its volume expansion of about 1-4 times, it will squeeze the concrete, which will lead to cracks or cracks to further expand, and even cause the failure of the protective layer of concrete. All these will lead to the reduction of structural durability and safety.

(4) Collective damages caused by water include direct penetration of water, intrusion of rainwater, capillary water and moisture collection in the pores caused when the temperature is lowered to the dew point, absorption of water by water-retaining agents, or moisture seeping from the ground into the walls. In addition, the negative impact of water may also be caused by moisture absorption of salts and microbial contamination.

2. What are the types of waterproof agents?

To protect a building, it is necessary to find a waterproofing agent that prevents the entry of water from the outside without inhibiting the transfer of moisture from the inside to the outside. Waterproofing agents applied to waterproof mortar can be divided into four categories according to their main components:

![]()

(1) Waterproof agent based on chloride metal salts:

This kind of waterproofing agent is easy to cause corrosion of steel.

(2) Waterproofing agent based on sodium silicate (i.e., water glass),:

This kind of waterproofing mortar in the project generally only uses its quick-setting effect and adhesion, to repair leakage and surface treatment.

(3) Water-repellent substances as the base material (fatty acid metal salts):

Although the unit cost of the products is relatively low, its main disadvantage is that the mixing time is long and difficult to disperse and significantly reduces the strength of cement products.

(4) Silicone waterproofing agent:

This type of waterproofing agent has good mixing properties to apply maximum repellency so that the mortar as a whole produces waterproofing and maintains the long-term effect after fully cured, and it has no effect on the bond strength of the surface and has no negative impact on the environment. Preventing water from entering the mortar at the same time, it can also keep the mortar in an open state, allow water vapor diffusion, and not turn yellow.

![]()

3. What is a silicone waterproof agent?

Silicone water repellents are chemicals containing silicone components that chemically bind to the surface of the material to apply maximum repellency. This waterproofing agent has excellent water resistance, weather resistance, chemical corrosion resistance, and other properties, it can effectively improve the waterproof performance of the material to extend the service life. It needs to be used in a ventilated area and fully cured.

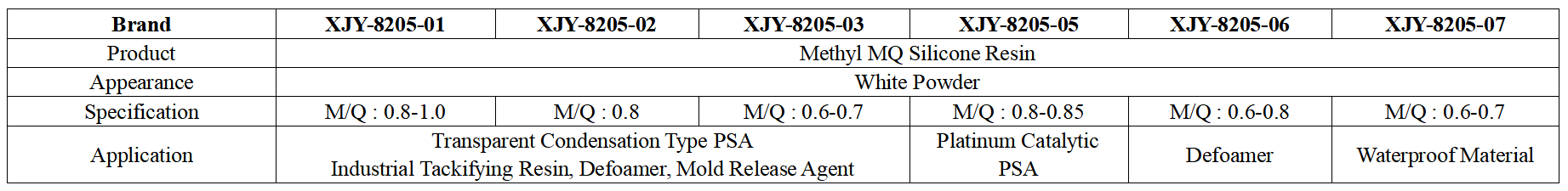

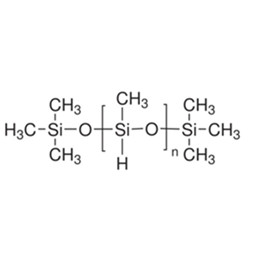

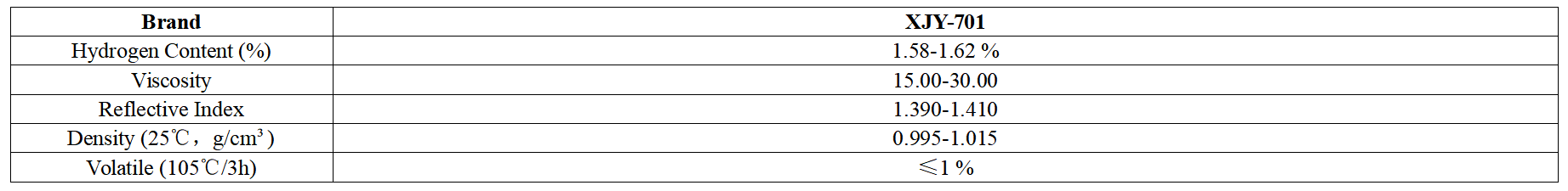

XJY-701 Polymethylhydrosiloxane can be crosslinked to form a film at low temperatures under the action of metal salt catalyst to form a waterproof film on the surface of various materials, which can be used as a waterproofing agent for fabric(such as sleeping bags), artificial marble, glass, vinyl tiles, ceramics, paper, leather, metal, cement, marble, galvanized metal and so on, and it can be used as a waterproofing agent in the field of construction (such as factory waterproofing).

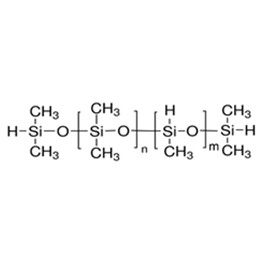

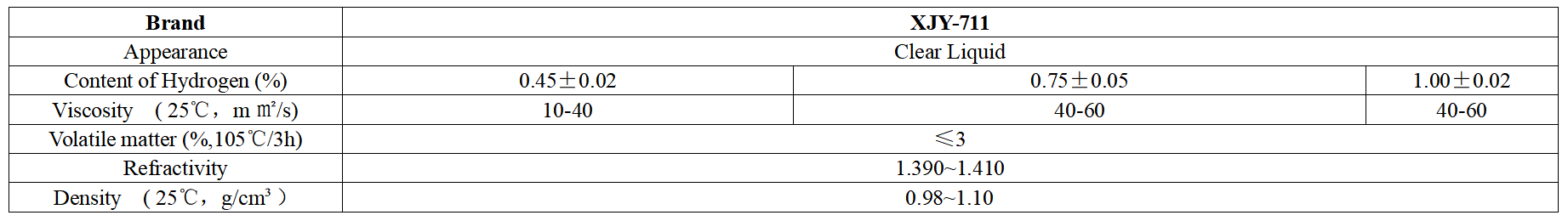

XJY-711 Hydride-terminated Methylhydrosiloxane/Dimethylsiloxane Copolymer can be used as a water-repellent in buildings and apply maximum repellency.

XJY-8205 Methyl MQ Silicone Resin is a solid powdered resin that provides excellent water resistance and forms a durable film. It repels water and stains and can be used as a water repellent specially formulated.

![]()

4. What is the principle of silicone waterproofing agents?

Silicone waterproofing agent is an efficient and environmentally friendly waterproofing material, and its waterproofing principle is mainly based on the special chemical properties of silicone compounds. The active silicon atoms in the silicone waterproofing agent can react with the hydroxyl groups on the surface of the building material to form a chemically bonded waterproof barrier. This barrier not only repels water but is also able to resist the erosion of the external environment, to protect the building materials from water damage (such as factory waterproofing).

In the treatment process of silicone waterproofing agent, it is first necessary to evenly apply the waterproofing agent to the surface of the building materials. Subsequently, the active ingredients in the waterproofing agent will penetrate into the interior of the material and have chemical reactions with the hydroxyl groups on the surface of the material. These chemical reactions lead to the formation of chemical bonding between the waterproofing agent and the building material, thus enhancing the adhesion and durability of the waterproof layer.

As the reaction proceeds, the waterproofing agent forms a dense waterproof layer on the surface of the building material. This waterproof layer has good hydrophobic properties and can effectively prevent water from penetrating through the surface of the material to the interior. At the same time, the waterproof layer is also able to resist the external environment of ultraviolet rays, acids and alkalis, and other unfavorable factors of erosion, and has long-term maintenance of the waterproof effect.

![]()

5. What are the features of silicone waterproof agents?

(1) Efficient waterproofing:

The silicone waterproofing agent formed has excellent hydrophobic properties and can effectively prevent water penetration into the building materials, to ensure the long-term waterproofing of the building safety.

(2) Environmentally friendly and harmless:

Silicone waterproof agent has no harmful substances in the production and use, which is harmless to the environment. At the same time, the chemical reaction between the waterproofing agent and building materials will not produce harmful substances that are harmless to human health.

(3) Strong weather resistance:

The waterproof layer formed by the silicone waterproof agent has good weather resistance and can resist ultraviolet rays, high temperature, low temperature, and other unfavorable environmental factors, to maintain a long-term waterproofing effect.

(4) Construction is simple:

Silicone waterproofing agent construction is simple, it only needs to coat the waterproofing agent evenly on the surface of building materials(as fine mist form). At the same time, the waterproofing agent's requirements for the construction environment are low and can be suitable in a variety of construction environments.

![]()

(5) Wide range of applications:

有机硅防水剂适用于多种建筑材料的防水处理,如混凝土、砖石、木材等。此外,该防水剂还可用于地下室、屋面、墙面、工厂的防水处理。

(6)透气性好:

有机硅防水剂具有一定的渗透性,可有效阻止水汽在材料内部的积聚,减少建筑材料因受潮而遭受的损坏。

(7)耐化学腐蚀性:

有机硅防水剂具有良好的耐化学腐蚀性能,能抵抗酸、碱等化学物质的侵蚀,保证防水层的长期稳定性。

6、如何让有机硅防水剂发挥更好的性能?

特殊配方有机硅防水剂凭借其独特的防水原理和优异的性能特点,已广泛应用于建筑工程。它不仅能有效保护建筑物免受水损害,还能提高建筑物的使用寿命和安全性。随着科技的不断发展,有机硅防水剂在未来将发挥越来越重要的作用,其应用范围已不再局限于单一领域,而是扩展到其他领域。如何提升特殊配方产品的竞争力?

鑫吉源有机硅是中国领先的有机硅MQ树脂和VMQ有机硅制造商之一,在有机硅行业拥有30多年的研发和生产经验,并拥有超过15项相关专利和技术支持。我们的有机硅原材料产品能够满足建筑领域的需求,并支持提供多样化的定制化大批量解决方案。立即添加到您的购物车。

![]()