With the booming development of the rubber and plastics industry, the use of release agents is becoming more and more widespread, especially in recent decades, the rapid development of injection molding, extrusion, calendering, molding, laminating, and other processes promotes the development of release agents. So why use silicone mold-release agents in the industry?

Non-silicone type mold release agent usually applies paraffin, fatty acid, etc. as a release agent, is the simple agent. If the working temperature is too high, the mold release agent is prone to thermal decomposition, carbonization, and other ills. Organic fluorine polymers beyond the permissible temperature may also release toxic substances.

Silicone mold release agents are available in a variety of forms and dosage forms, which facilitates adaptation to different options: As the skeleton of silicone polymers consists of silicone-oxygen bonds, the heat resistance is excellent, and the stabilization temperature exceeds that of almost all types of rubber, which can withstand a variety of plastic product processing temperatures, especially non-migratory silicone mold release agents based on silicone resin, not only the high working temperatures, but also the release agent components are stable and do not migrate, demonstrating an ultra-long service life of the release agent. And Silicone is a low surface energy material, so its product has the smallest stripping force when demolding, which means that the product is easiest to demold when using silicone demolding agents.

Here's some information about it:

- What is mold release agent?

- What are the criteria for good mold release agents?

- What are silicone mold release agents?

- What are the advantages of silicone mold release agents?

- What are the types of silicone mold release agents?

- What are the applications of silicone mold release agents in industry?

- How to make silicone mold release agents?

1. What is mold release agent?

The release agent is a functional substance between the mold and the finished product. Mold release spray is a type of processing aid that prevents molded products made of elastomers such as rubber, plastics, and other materials from bonding to the surface of the mold and serves to make it easy to release the mold. The aerosol carries the resin release, which, when applied, covers the resin mold. Mold release spray is used to form a semi-permanent film layer that does not participate in the reaction, isolating the mold and the product so that the product can be easily removed from the mold. Release agents require high adhesion to the mold and do not react with the product.

Mold release agents are divided into inorganic release agents, organic release agents, and organic polymer release agents. Early commonly used organic release agents are wax, stearic acid, metal soap, surfactants and grease, petroleum jelly, etc; Commonly used inorganic powder release agents are talcum powder, mica powder, clay, silica clay, lead powder, and white clay. With the development of polymer technology, the emergence of organic polymer release agents is prosperous, such as Polyethylene Glycol, Low Molar Mass Polyethylene, Polyether surfactants, silicone, and Organic Fluorine.

2. What are the criteria for good mold release agents?

The general requirements for good mold release agents are:

(1) Inert, no chemical reaction with the material to be stripped;

(2) Non-corrosive to the mold, stable at high temperatures, no decomposition to produce carbon deposits;

(2) Non-corrosive to the mold, stable at high temperatures, no decomposition to produce carbon deposits;

(3) Low surface tension and good mold release effect;

(4) Good leveling, leaving no blanks on the surface of the mold so that the surface of the product is smooth;

(5) It will not affect the post-processing;

(6) Good dilution stability, easy to find diluent;

(7) Low dosage, low cost;

(8) A coating can be used many times.

The raw material of silicone mold release agent provided by XJY Silicones fully meets the above criteria, and the silicone mold release agent produced is resistant to high and low temperatures, and has low surface tension, thus increasing the number of reuse times, improving downstream customer's productivity, and lowering the production cost. In high-temperature castings, tire molding and other fields have the best results.

3. What are silicone mold release agents?

The silicone release agent is a class of processing aids between the mold and the product so that it is easy to release, and can prevent rubber, plastic, elastomer, or other materials molded products from adhering to the mold, the use of release agents can reduce the adhesion between the product and the mold surface.

The earliest silicone mold release agent is mainly Dimethicone, which will be coated on the mold, polysiloxane in the mold surface spread into a single molecular orientation arrangement, its lateral group-methyl group (or alkyl, phenyl) array in the mold surface tightly, forming a layer of an inert lubrication layer, so that the mold products are very easy to take out of the mold from the mold, and the mold products of anti-wear performance and scratch resistance can also be improved.

Release agents have two effects: one is the filling effect, the release agents fill the mold surface of the deep holes, grooves, and cracks; the second is the lubrication effect, the release agents reduce the friction between the product and the mold surface. Silicone materials with low surface tension have two effects.

![]()

4. What are the advantages of silicone mold release agents?

(1) Better heat resistance than the general organic mold release agent

It is not easy to crack when the temperature rises: while the organic release agent will "burn" at high temperatures, generating carbonized precipitates - carbon deposits, which gather on the surface of the mold, making the molded product fail.

(2) Low surface tension and excellent fluidity

It can effectively infiltrate the whole surface of the mold, and even in the tiny parts of the mold, it can also spread to form a very thin lubricating film.

(3) Small viscosity

The viscosity temperature coefficient is small, under different temperatures can be in the mold surface to form a continuous film: and organic mold release agent at low temperatures when the mobility becomes poor.

(4) No contamination

It will not lead to molded parts surface defects.

(5) Low volatility

It can reduce smoke and can reduce the possibility of fire.

(6) Good chemical stability

Its contact with the material does not produce a chemical reaction, and will not corrode the mold.

(7) Good oxidation resistance

It has increased stability and improved overall performance, extended service life.

(8) Good physiological inertness

Therefore, it can be safely used for people and the environment.

(9) Low dosage

Low dosage can reduce the cost of demolding, while not affecting the accuracy of the molded product, compensating the cost.

![]()

5. What are the types of silicone mold release agents?

Silicone mold release agents can be divided into two kinds, internal release agents and external release agents.

(1) External silicone mold release agent takes dimethyl silicone oil as the main raw material. It is directly coated on the mold, mainly used for epoxy resin products and silicone mold release.

(2) The internal silicone mold release agent uses high-viscosity silicone oil, which is mixed with raw materials and oozes out of the product raw materials to form a film at a certain temperature. (The internal mold release agent improves the fluidity of the masterbatch, reduces the surface friction coefficient, and improves the abrasion resistance, lubricity, gloss, and hydrophobicity of the finished product). The addition of multifunctional reactive MQ silicone resins, hydroxyl silicone oils, and magnesium stearate to thermoplastic resins also improves the flame retardancy of the finished product. It is suitable for mold release in the automotive industry, fitness equipment, medical facilities, home culture, education, and entertainment.

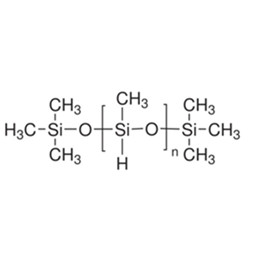

XJY-701 Polymethylhydrosiloxane is a high molecular weight organic synthetic with a general chemical structure and is high hydrogen silicone oil, which can be used as a mold release agent.

![]()

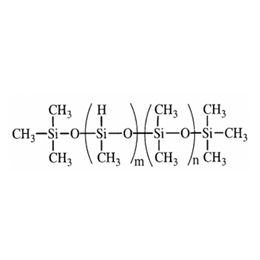

XJY-702 Methylhydrosiloxane, Dimethicone copolymer is non-toxic and tasteless, with active genes, under the action of a catalyst, it can react with double bond, hydroxyl, and other groups, it is the basic raw material of polyether-modified silicone oil, and it can be made into mold releasing agent. In addition to the characteristics of dimethyl silicone oil, this product can produce addition and cross-linking reactions due to the presence of active hydrogen.

![]()

6. What are the applications of silicone mold release agents in industry?

With the development of technology, silicone mold release spray has many different structures, properties, and varieties, which can be applied to a variety of industrial fields, commonly such as tires, shoes, metal casting (especially magnesium, aluminum, and zinc alloy metal castings), rubber and plastic and other materials; In addition, many industrial fields also benefit from the unique properties of silicone release agents, such as concrete, glass, glass fiber, asphalt, casting shell and core manufacturing industry, spray starch, adhesives, wood, yarn/thread lubricant and wire/cable lubricants.

With the recent development of plastics processing technology such as injection molding, extrusion, calendering, molding, and laminating, there are increasing opportunities to develop silicone mold release agents for use in this field.

6.1 How to apply silicone mold release agent in PU?

(1) In the molding of PU products

PU materials, like silicone materials, are also a large series of products, such as PU resins, PU plastics, PU elastomers and synthetic leather, PU fibers, PU coatings, PU sealants, PU adhesives, and PU foam products. In the PU plastic, PU elastomer, and PU foam molding, in order to facilitate the release of products, it is necessary to use a mold release agent because of the strong adhesion of PU on most materials. For the use of long-lasting mold release agents needs to choose silicone and other mold release agents.

Silicone is a relatively new release material with high performance and is currently mainly used in PU shoe soles, automotive parts, and automotive interior decoration of the release. With the depth of the scope of application, people will find silicone release agents in the cost-effective superiority of silicone release agents, the understanding of silicone release agents is improving, and silicone release agents in PU molding products are more and more widely used.

(2) In the PU foam molding process

PU hot vulcanization foam molding process is that the A and B two kinds of components are injected into the mold metal tool at 160 ℃ above sulfur for 10 or 14min, cooling the mold after demolding and getting the parts. It can be used emulsion-type and solvent-based silicone mold release agent.

The cold vulcanization foam molding process has developed faster in recent years, the mold temperature of this method is 35 ~ 45C, which has energy savings, improved productivity, available cheap non-metallic molds, and other advantages, there is a gradual replacement of the trend of the hot vulcanization process. This method mainly uses a solvent-type silicone mold release agent.

PU foam can be divided into hard foam, semi-hard foam, and soft foam. Hard foam is mainly used in refrigerators, automobiles, and industrial insulation materials; semi-hard foam is mainly used as automobile interior parts and shoe soles; soft foam is mainly used in automobiles, furniture seat cushions, and shoe soles. Silicone mold release agent is mainly used in the release of hard and semi-hard foam. Silicone mold release agent in the shoe industry application development is better, which is mainly used for shoe sole sandwich and shoe outsole mold release.

Ordinary PU soles mainly use water-based mold release agents. Silicone mold release agent with MQ resin is a kind of semi-permanent mold release agent with wide application. It has excellent mold coverage, good thermal stability, no carbonization, less buildup on the mold, no residue on the mold, no need to over-clean the surface of the molded part, and it can be used once to play the role of mold release in multiple molding cycles. After adding MQ resin, the content of the water-based mold release agent is about 60% silicone resin emulsion. It can be used diluted directly but needs to be prepared for immediate use. There is no need to clean the mold prior to application because of its excellent wetting and spreading properties and good mold release.

(3) PU semi-permanent silicone mold release agent

Semi-permanent mold release agents with silicone and fluorine-containing compounds as the main body have low surface energy, high thermal stability, and chemical stability so it has high surface activity, high thermal stability, and high chemical inertia. Compared with other types of release agents, the advantages of this release agent are: the quality of the release agent itself is stable, the product storage period is long; the concentration of diluted use is low, the continuous demolding effect is good; the demolding performance for high-viscosity materials and products is good, demolding molds and products basically is non-polluting, molds do not need to be cleaned, do not affect the secondary processing of products.

PU semi-permanent silicone mold release agent is a milky white liquid, mainly composed of silicone resin and silicone oil, which adds the appropriate amount of emulsifier emulsification.

① Compared with ordinary silicone oil-based release agents, the addition of special silicone resin effectively improves the wear resistance of the release layer and reduces the migration of the release agent components to the product.

② Compared with mineral oil-based release agents, PU semi-permanent silicone release agents have excellent heat resistance and chemical stability in addition to excellent lubricity and mold release. Therefore, like paraffin and inorganic materials, it will not contaminate or damage molds and molding materials.

③ In addition, no odor or fumes are produced after decomposition. Therefore, it has an extremely wide range of applications and has remarkable effects in improving product quality and operational efficiency.

![]()

XJY-8205 Methyl MQ Silicone Resin Powder is a solid powdered resin that provides excellent transfer resistance and water resistance and also forms a long-lasting film that can be used as a mold release agent.

![]()

6.2 How to apply silicone mold release agent in metal die casting?

Metal die-casting molding is a precision casting method that adds the molten aluminum alloy, zinc alloy, and other non-ferrous metals into the mold filling, and cooling solidification, forming under high pressure.

Metal die casting process uses mold release agents role for metal liquid and die casting mold to provide effective isolation between the protective layer to avoid the metal liquid directly brushing the cavity and core surface, and to improve the working conditions of die casting mold, reduce the heat conduction of die casting mold, protect the flow of the metal liquid and improve the molding of the metal liquid; In such a high temperature, it still provides excellent lubricating properties, in order to mold easily to push out the die casting and improve the surface quality of die casting. Die-casting surface quality is good, preventing sticking mold.

Metal casting temperature is very high, more than the general use of organic mold release agent temperature. Silicone material's high-temperature resistance is better than other organic compounds, and more suitable for metal casting mold release agents.

Silicone mold release agent is mainly used for aluminum alloy die-casting mold release. Such as automotive aluminum alloy die castings (including engine box and box cover, gearbox, sprocket room, timing gear room cover, connecting bridge, wheel hoops, etc.), communications aluminum alloy die castings (including magnetic card telephone shell, mobile communication transmission and reception box, set-top box, etc.), elevator aluminum alloy die castings (including GHT1000 mm, GHT 800 mm, GHT 600 mm type elevator type), aluminum alloy die casting, electromechanical and household appliances, aluminum alloy die castings (including motor cases, engine cases, mechanical parts, various types of lamps and lanterns, electric baking appliances, household appliances, etc.) of the mold.

6.3 How to apply silicone mold release agent in the tire preparation?

6.3.1 Tire Manufacturing Process and Tire Structure

The tire manufacturing process cannot be separated from the vulcanization molding process. Because rubber is a viscous material, its viscosity can be molded together with different rubber parts to become a tire. Heated vulcanization also allows the tire to stick to the mold when it is removed from the mold. Unlike most rubber products, tires have two interfaces between the rubber and the mold and the rubber and the bladder. They have completely different chemical compositions and require different mold release agents. It is impossible to produce tires efficiently without a release agent.

![]()

6.3.2 Types of Tire Release Agents

(1) Disposable tire release agents.

During tire curing, the adhesion at the rubber-mold interface is not necessarily so great as to produce a sticky mold, which does not require the use of a release agent. However, there are some rubbers that stick very firmly to the mold when heated and pressurized for vulcanization. If a release agent is not used, the mold release can be damaged by thermal tearing or production can be interrupted by the tire remaining in the mold. The most common method of overcoming sticking to the mold is to use a release agent.

If disposable release agents such as various oils, waxes, emulsions (or solvents) of oils and waxes and emulsions (or solvents) of silicone oil are used. These release agents are taken out of the mold when the tire comes out of the mold at the end of vulcanization, so the release agent must be reapplied before each vulcanization. Oils and waxes are inexpensive but they are absorbed by the rubber during vulcanization easily. Applying too little, the release agent can stick to the mold; applying too much, the release agent will migrate to the surface of the tire, producing an unwanted lubrication film. While silicone oil as a disposable release agent has a high lubricating effect, the amount of very small has an excellent mold release effect and it is easily absorbed by the rubber.

(2) Silicone semi-permanent tire release agent.

Disposable release agent has certain limitations: each time it needs to be coated with a large number of manpower and use a variety of raw materials before vulcanization; it may migrate to the surface of the tire so that the tire's joints parts open; emulsion-type release agent surfactant in the vulcanization temperature is unstable, the best way to increase mold scaling is to use silicone semi-permanent mold release agent.

This type of release agent in the polysiloxane is not a simple dimethyl silicone oil, which contains active groups (such as hydroxyl or alkoxy groups) or silicone resin, which in addition to maintaining the high lubricity of silicone oil and the characteristics of the dosage is small under certain conditions, but also can form a layer of film on the surface of the mold, which can be subjected to adhesive scratching, and can be used many times (different semi-permanent mold release agent cycle varies greatly, depending on the composition of the mold release agent, the type of mold, the nature of the rubber and vulcanization conditions), but also may reduce the amount of mold scaling and will not produce migration.

Semi-permanent mold release agents need to have two functional structures, one enables the release agent to form a solid film on the surface of the mold; the other is able to reduce the raw (embryo) rubber and mold kinetic friction, to prevent the rubber from adhering to the surface of the mold after vulcanization. The ratio of the two materials can be adjusted as needed. Heating accelerates curing and increases the life of the coating. Catalysts can also be added to lower the curing temperature and reduce the curing time.

7. How to make silicone mold release agents?

Silicone mold release agent is prepared from Organosiloxane, its advantages are good heat resistance, moderate surface tension, easy to form a uniform isolation film, long release life non-toxic, good luster, no affinity with the resin, etc., and widely used in plastics, rubber, and other various occasions. How to make your products more competitive in the market?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our MQ silicone resin can provide customized solutions according to your application requirement specifications (silicone mold release agent).