In the LED industry chain, LED packaging is where optical performance and long-term reliability often get decided. For high power LED devices (including UVB LEDs), the selection of LED packaging materials, outer lens materials, and the overall encapsulation process method can directly shape LOP stability, stress evolution, and lifetime.

Silicone resin is a preferred LED encapsulation material because it can be formulated optically clear, helping maintain high light output and luminous uniformity. Reducing the refractive-index mismatch improves light extraction efficiency and can boost light output power. Compared with many epoxy resins, silicone materials typically offer better heat resistance, high temperature performance, and heat aging resistance, which is critical for high-power LED devices. Silicone’s lower modulus and more suitable thermal expansion behavior make it a low-stress material, reducing internal stress, cracking, and delamination during thermal cycling. It also supports flexible processing and stable pot life.

- Why “packaging material” matters in UVB LEDs

- How does silicone resin encapsulant boost light extraction efficiency?

- Reliability reality: what happens during long-term operation

- Silicone vs epoxy in LED encapsulation: why the industry keeps shifting

- Mechanical and adhesive properties: stress is the silent lifetime killer

- Process options: from silicone resin to molded silicone polymers

- What does this paper mean for future research direction

1. Why “packaging material” matters in UVB LEDs

UVB LEDs face harsh operating conditions. Compared with conventional epoxy resins used in many white LED devices, UVB operation tends to expose material weaknesses faster, including poor heat resistance and optical deterioration. That is why the industry continues to explore general silicone materials, silicone polymer systems, and silicone-modified materials that can survive UV exposure and heat.

The study shows a packaging structure using encapsulating silicone between a UVB LED chip and a quartz glass cover. In that structure, the light output power was reported to be 13.8% greater than the corresponding structure without the silicone encapsulant.

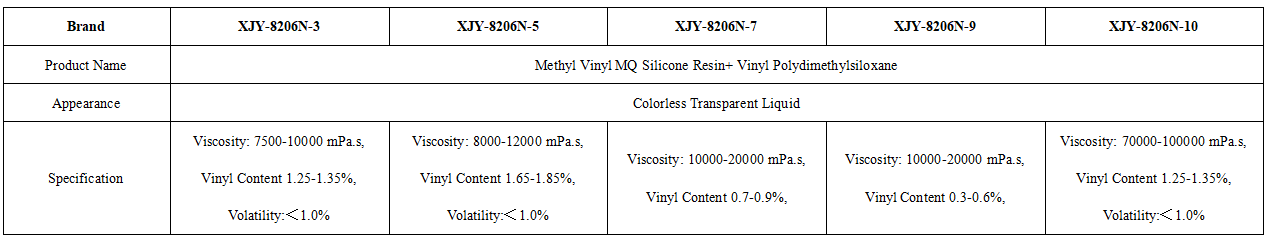

XJY-8206N VMQ Silicone Resin (Trimethylvinylsiloxysilicate) is a colorless transparent liquid resin composed of vinyl MQ silicone resin and vinyl polydimethylsiloxane. It can be used for LSR liquid addition molding silicone rubber, LED packaging adhesive, and other two-component addition adhesives.

2. How does silicone resin encapsulant boost light extraction efficiency?

The core mechanism is optical. When there is a large refractive index gap, total internal reflection increases, and photons get trapped. By inserting a silicone encapsulant, the refractive index gap between sapphire (chip side) and air is reduced, lowering total internal reflection and improving light extraction efficiency.

Practical translation:

If you want a higher LOP, you care about refractive index matching.

In many LED designs, the higher the refractive index (within a stable, low-absorption system), the more helpful it can be for extraction, so “high transparency materials” with a suitable high refractive index become valuable.

The paper also states that filling silicone improved LEE, and the LOP enhancement was attributed directly to the encapsulating silicone influence.

3. Reliability reality: what happens during long-term operation

UVB LED reliability is not only about the chip. The study reports long aging and shows that in the proposed silicone-based package types, LOP decreased substantially over time. In the conclusions, the authors report reliability tests over 3500 h, where LOP decreased to 45.3%, 48.6%, and 50.3% of initial values for the three proposed packaging types.

They also observed that cracks appeared in the encapsulated silicone after 1500 h and were evident after 3500 h, but the different degradation rates were not obviously correlated with crack appearance.

A key engineering recommendation in the paper:

If silicone is used to encapsulate the cavity in this style of package, the hermetic cover should be removed to avoid cracks occurring in the encapsulated silicone.

The paper further discusses that silicone between the chip and attached quartz glass may deteriorate due to thermal stress and UVB irradiation, and stress can be more obvious when silicone touches the quartz glass.

4. Silicone vs epoxy in LED encapsulation: why the industry keeps shifting

Many LED packaging lines have experience with LED packaging epoxy resin or modified epoxy resin. Epoxy has strengths, but for high temperature performance and UV exposure, epoxy systems can show faster degradation and stress-related issues.

That is why you see multiple technology directions:

silicone modified epoxy resins (and silicone epoxy resin) to combine “both epoxy resin” handling familiarity with silicone’s stability

Introducing silicone functional groups into epoxy networks via the epoxy modification method (including the chemical copolymerization method) to improve heat aging resistance, UV resistance, and reduce brittleness

Moving to pure silicone encapsulants: silicone resin, silicone gel, or LSR routes

In practice, “introducing silicone functional groups” often means selecting reactive groups such as hydroxyl and alkoxy groups or epoxy groups (depending on resin design) so the network can reach a workable high cross-linking density without creating large internal stress.

5. Mechanical and adhesive properties: stress is the silent lifetime killer

For LED packaging, you balance:

Optical properties (clarity, refractive index, haze growth)

mechanical properties (modulus, toughness, crack resistance)

mechanical and adhesive properties at interfaces (chip, ceramic, lens, lead frame)

thermal expansion coefficient matching to reduce stress

In many cases, silicone is preferred as a “material soft/low stress materials” solution that helps buffer thermal mismatch, while still being optically clear.

6. Process options: from silicone resin to molded silicone polymers

Depending on your product and where you sit in the entire industry chain (upper and lower levels), silicone solutions can match multiple manufacturing flows:

Silicone resin encapsulant dispensing and curing for UVB/UV packaging

Molded liquid silicone rubber for lens or housing parts (including injection molding, molding silicone rubber, and producing molded silicone polymers)

Hybrid approach: silicone encapsulation plus high-transparency inorganic materials (like quartz) where needed

For formulation families, many customers evaluate:

vinyl silicone resin and vinyl containing linear polysiloxane (often paired with a crosslinker such as hydrogen-containing silicone oil in addition-cure systems)

selected silicone oil grades to tune flow and processing

targets like very small shrinkage rate and a stable pot life during production

7. What does this paper mean for future research direction

The paper makes it clear: silicone can improve LOP through optical design, but long-term UVB aging introduces stress and deterioration mechanisms that still need optimization.

That is a realistic future research direction for UVB packaging: optimize stress, transparency retention, and structure choices (like whether a hermetic cover is necessary).

8. How to choose silicone materials?

As a silicone resin manufacturer, we supply silicone materials used as led encapsulation materials and silicone packaging materials, and we support customers with raw material selection and application matching.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone cosmetics field and support the provision of diversified customized solutions.