In high-temperature masking tape, insulation tape, and many industrial tapes, silicone pressure-sensitive adhesive systems are among the most important pressure-sensitive adhesives on the market. These silicone pressure-sensitive adhesives (often shortened to silicone PSA or silicone PSAs) are widely used where a wide temperature range, high heat resistance, excellent cold resistance, and strong chemical resistance are required.

Compared with acrylic pressure-sensitive adhesives or rubber-based pressure-sensitive systems, a silicone pressure-sensitive adhesive offers several key advantages:

- A much wider service temperature range, from very low temperatures up to extremely high heat

- Excellent resistance to chemicals, solvents, moisture, and even fungus or mildew in demanding environments

- The ability to bond to low-energy surfaces and difficult substrates, such as fluoropolymers, polyolefins, and silicone release liners

- Good clarity and optical properties for films, protective films, display films, and plastic films

However, for these pressure-sensitive adhesive systems to deliver the right adhesive properties, adhesion, cohesion strength, and clean removability, the choice of silicone resin—especially MQ silicone resin and methyl/phenyl silicone resins—is critical.

- What is the backbone of silicone PSA?

- Methyl vs. Phenyl – Balancing Performance and Cost

- What is the real value of silicone resins in applications?

- What Should Formulators Look for When Selecting Silicone Resins?

- What Can a Silicone Resin Supplier Offer to Tape Manufacturers?

- How to make silicone PSA perform better?

1. What is the backbone of silicone PSA?

A typical solvent-based silicone pressure-sensitive adhesive is built from two core raw material components:

(1) High Molecular Weight Silicone Gum

Methyl silicone gum or methyl/phenyl copolymer gum

Provides flexibility, low-temperature performance, and good bonding to various surfaces and substrates

(2) Highly Branched MQ Silicone Resin (MQ Resin)

Composed of M units (SiO₀.₅R₃) and Q units (SiO₂)

R can be methyl, phenyl, or other organic groups, providing a versatile, wide array of design options

Has a high glass transition temperature (Tg) and a rigid structure

It is essential to build cohesive strength, adhesive strength, and high temperature stability.

In a suitable solvent system (often toluene, aliphatic hydrocarbons, or their blends), silicone gum and MQ resin are formulated and processed together. Under the right catalyst and curing process, they condense and later crosslink to form a three-dimensional network. The coating is then applied as a coating onto backings such as polyester, polyimide, cloth, or release papers, and further cured to build the final adhesive performance.

For the formulation engineer, selecting and adjusting the type and level of silicone resin allows fine-tuning of:

- Tack, peel, and adherence (peel adhesion)

- Cohesive strength (internal cohesion strength) and high temperature shear

- Clean removability after heat aging or long-term insulation use

- Adhesion to different surfaces and substrates (metals, plastics, films, foams, and textiles)

In simple words:

Silicone gum determines whether it sticks; silicone resin determines how strongly it sticks, how it behaves at high temperatures, and how cleanly it can be removed.

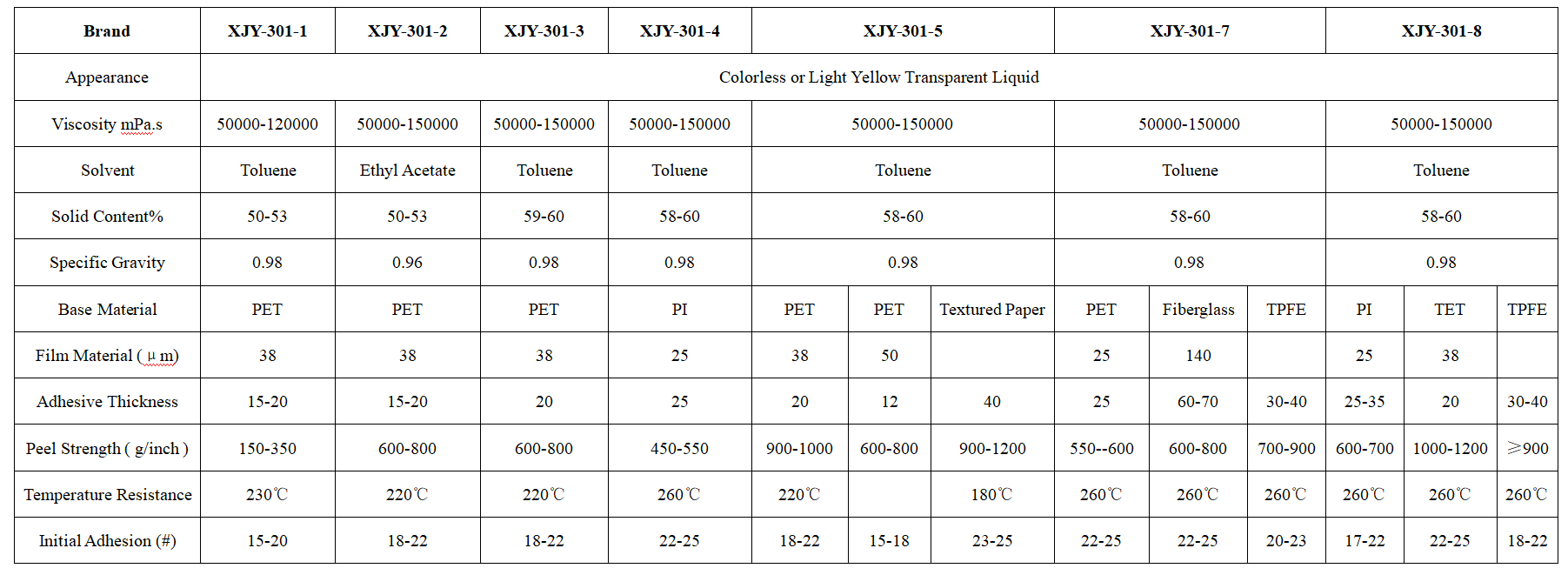

XJY-301 Silicone pressure-sensitive adhesives

It is made from the specific structure of silicone resin and high molecular weight polydimethylsiloxane in cooperation with organic adhesive, which is suitable for specific scene conditions.

Compared with natural rubber, it is characterized by heat resistance, high stability, good electric insulation, good transparency, high peel adhesion, and chemical resistance etc. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care, and mica tapes, splicing tapes, protective films, and other fields.

2. Methyl vs. Phenyl – Balancing Performance and Cost

In high-temperature-resistant silicone PSA tapes, two major families of silicones are used:

Methyl silicone pressure-sensitive adhesive systems

Phenyl silicone pressure-sensitive adhesive systems

The main difference is whether phenyl groups are introduced into the backbone or side chains.

Phenyl silicone PSAs typically provide:

Even better, high heat resistance and thermal stability

Improved performance at very high temperatures, where vibration, thermal cycling, and aggressive chemicals are present

However:

Phenyl silicone gum and phenyl silicone resins are more expensive compared with pure methyl systems

This raises the cost of the total pressure-sensitive adhesive system

Methyl silicone PSAs usually offer:

More competitive cost, especially for large-volume industrial applications

A good compromise between adhesive properties, adhesive strength, and cost

With the right silicone resin and MQ silicone pressure-sensitive formulation, they can reach excellent resistance to heat, moisture, solvents, and chemicals

Many tape makers, therefore, ask:

“How can we use methyl silicone pressure-sensitive adhesives to get performance closer to phenyl systems, while still controlling cost?”

The answer is to optimize the resin package: using well-designed MQ silicone resins and methyl/phenyl silicone resins to assist the engineer in improving anchorage, improving bond strength, and enhancing high-temperature performance.

3. What is the real value of silicone resins in applications?

End users care less about theory and more about concrete tape applications. Their typical questions are:

“What kind of silicone resin is suitable for my application?”

“Which raw material can help me reduce residue and improve high-temperature adhesion?”

Below are several key fields where silicone pressure-sensitive adhesive systems and silicone resins are widely supplied and used.

(1) Electronics & Electrical – High Temperature Soldering and Insulation Tapes

In electronics and electrical insulation, silicone PSAs are used in:

Solder masking tapes for PCB and FPC

High temperature insulation tape for motors and transformers

Protective films and special film applications for displays and sensitive electronic parts

These products must offer:

Reliable high-temperature adhesive performance during soldering, reflow, curing, and other harsh processing steps

Strong adhesion and cohesive strength to PI and PET films, copper, stainless steel, and other substrates

Excellent electrical insulation, chemical resistance, and moisture resistance

Clean removability, with minimal or zero residue

Here, MQ silicone resin is key to:

Build internal cohesion strength so that the coated adhesive layer does not slide or split under stress and vibration

Maintain adhesive properties and reliability over a wide temperature range

Work with suitable primer systems to improve anchorage to difficult surfaces

When formulated correctly, these silicone PSA systems show high stability in contact with solvents, fluxes, and various chemicals encountered in electronic processing.

(2) Automotive – Engine Compartment, Wire Harness, and Paint Masking

In the automotive sector, high-temperature tapes are used for:

Masking around engines and exhaust components

Fixing and bundling wire harnesses in areas exposed to heat and vibration

Body paint and bake masking tape on polyester, steel, and other backings

EV battery pack insulation and protection

In these applications, the adhesive must combine:

High adhesive strength and secure bonding to many substrates

Long-term stability at elevated temperatures, including exposure to oil, chemicals, and moisture

Easy, clean removability without damaging the surfaces or leaving heavy residue

By using optimized silicone resins and MQ silicone resins, automotive tape producers can achieve:

Better high temperature resistance and cohesive stability

Controlled peel, tack, and adherence to painted metals, plastics, and composites

Durable performance under vibration, temperature cycling, and outdoor sunlight

Compared with many standard acrylic pressure-sensitive adhesives from big brands such as Dow, a well-designed silicone pressure-sensitive adhesive often delivers superior temperature and chemical resistance and is more suitable for under-the-hood environments.

(3) Powder Coating & Industrial Coating – High Temperature Masking and Clean Removal

In metal finishing, industrial powder coating, and baking coating lines, silicone pressure-sensitive masking tapes are required to:

Resist high curing temperatures in powder coating ovens

Maintain line clarity and sharp masking edges

Offer clean removability even when removed hot

If the pressure-sensitive adhesive is not heat-resistant enough, the adhesive may soften, flow, or degrade, leading to:

Dirty edges and poor masking quality

Adhesive residue on metal surfaces and films

Extra processing steps and cleaning to remove adhesives

By choosing high Tg silicone resin and a well-balanced MQ resin package, powder coating masking tapes can be formulated to:

Provide strong internal cohesion, strength, and high temperature resistance

Work on polyimide, polyester, and cloth backings as well as papers

Offer a reliable balance between tack, peel, and clean removability

These advantages help coaters and fabricators reduce rework and discover more stable production windows.

4. What Should Formulators Look for When Selecting Silicone Resins?

As a silicone resin and silicone PSA raw material supplier, we often hear:

“My high temperature masking tape has poor shear and residue issues – which silicone resin can assist with that?”

“I want to move from a phenyl system to a more economical methyl silicone pressure sensitive adhesive – which MQ resin is suitable?”

Formulators should pay attention to several key factors when choosing silicone resins:

Resin Type and Structure

- Pure methyl MQ silicone resins, methyl/phenyl MQ silicones, and other silicone resins

- Each structure influences Tg, rigidity, compatibility, and overall adhesive properties

Resin / Gum Ratio (R/G Ratio)

- Controls adhesive strength, cohesive strength, and high temperature resistance

- Too low: insufficient cohesion strength and heat stability

- Too high: lower tack and flexibility, difficult processing

- Functionality, Catalyst and Cure Mechanism

Silanol, vinyl and other functional groups must fit the chosen catalyst and cure process

- Impacts crosslink density, volatility, and the ability to resist solvents, aliphatic hydrocarbons and other chemicals

Solvent System and Dilution

- Compatibility with solvents like toluene, xylene, and diluted blends

Viscosity and solids must match your coating and drying process so the adhesive layer is evenly coated

Target Applications and Backings

Electronics and electrical insulation tapes

Automotive high-temperature masking and insulation tapes

Industrial and powder coating masking tapes, protective films, and plastic films

Specialty applications on polyimide, polyester, cloth, and paper backings

Matching the silicone pressure-sensitive system to the real application is essential to get the best properties and long-term reliability.

5. What Can a Silicone Resin Supplier Offer to Tape Manufacturers?

From a raw material supplier’s perspective, we do more than just sell “a resin in a solvent.” Our goal is to help you formulate a better, more sensitive adhesive system.

For customers developing or upgrading high-temperature silicone pressure-sensitive adhesives and tapes, a professional silicone resin partner can:

Supply a portfolio of MQ silicone resins and related silicones, with different M/Q ratios and functionalities

Offer resin solutions optimized for electronics, industrial insulation, powder coating masking, and automotive applications

Recommend combinations of silicone pressure-sensitive materials, primer systems, and backings to improve anchorage, bonding, and adherence

Work with your coating and curing process to optimize viscosity, solids, cure schedule, and oven profile

By adjusting the resin package, you can:

Increase high-temperature cohesive strength and adhesive strength

Maintain strong adhesion yet still get clean removability

Improve overall reliability and stability of the adhesive system, even under sunlight, chemicals, moisture, and mechanical vibration

6. How to make silicone PSA perform better?

Whether you are working in electronics, automotive, or industrial coating, the demand for high-performance pressure-sensitive adhesives and high-temperature tape is growing. Customers expect:

- Strong, durable adhesion on a wide variety of substrates and surfaces

- A wide temperature range, plus high heat resistance and cold resistance

- Excellent chemical resistance, moisture resistance, and resistance to solvents and chemicals

- Reliable, clean removability with minimal residue

In all of these areas, silicone pressure-sensitive adhesives formulated with the right silicone resin and MQ silicone PSA technology can outperform many conventional systems.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone PSA field and support the provision of diversified customized solutions.