In both the construction industry and textile finishing, silicone waterproof agents have become indispensable for achieving long-lasting protection against water, moisture, and chemicals. From cement mortar and roof tiles to fabrics and floor tiles, silicone-based waterproofing agents are widely applied across building materials and industrial coatings. Why use silicone waterproof agent as a hydrophobic treatment for textiles?

Unlike traditional oil or wax-type repellents, silicone waterproofing treatments form transparent, colorless, and breathable films that protect the surface of concrete, wood, ceramics, or metal without affecting appearance.

They are also suitable for antique buildings, underground engineering, bathroom sealing, and roofing repairs — anywhere long-term moisture-proof performance is required.

This article explores how silicone waterproof agents work, their form, main materials, film-forming mechanisms, durability, and application techniques.

- What is Silicone Waterproof Agent?

- How the Waterproofing Mechanism Works?

- Processing & Application Guidelines

- Physical and Chemical Characteristics

- What are the applications across industries?

- Safety, Storage, and Handling

- How to make your waterproof perform better?

1. What is Silicone Waterproof Agent?

A silicone waterproof agent (sometimes called a silicone sealant or hydrophobic waterproofing agent) is a specially formulated product designed to protect porous materials like cement mortar, bricks, tiles, and plasterboard from soaking, rain, and moisture damage.

It is a main material in construction and repair work, providing a colorless layer that prevents water from penetrating deep into the substrate.

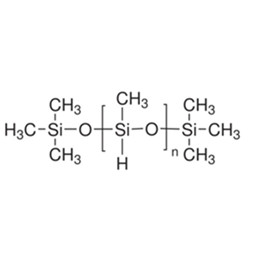

XJY-701-Polymethylhydrosiloxane

Under the action of the metal salt catalyst, it can be cross-linked into a film at low temperatures, forming a waterproof film on the surface of various materials, and can be used as a waterproofing agent for fabrics, glass, vinyl tiles, ceramics, paper, leather, metal, cement, marble, galvanized metal, and so on.

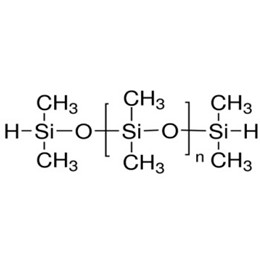

XJY-711 Hydrogen-terminated Methylhydrogensiloxane/Dimethylsiloxane Copolymer

It can be used as a water repellent for fabrics and buildings.

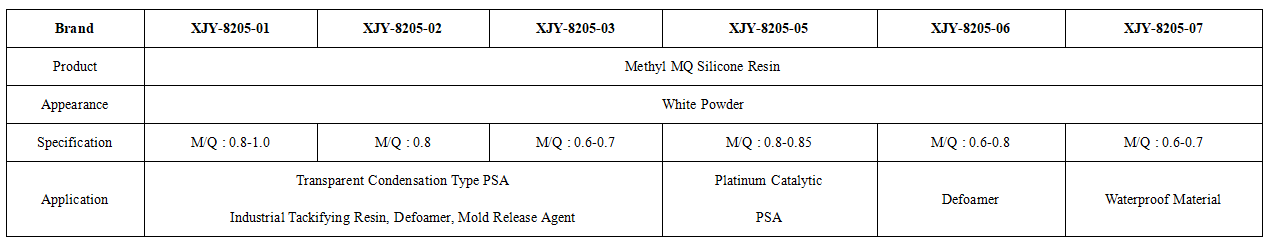

XJY-8205 Methyl MQ Silicone Resin

It is a solid powder resin that provides excellent water resistance, forms a durable film to does not shrink, and can be used as a water repellent.

Most silicone waterproofing emulsions are light yellow or transparent, making them suitable for decorative tiles, fabrics, and flooring where aesthetic integrity is important.

2. How the Waterproofing Mechanism Works?

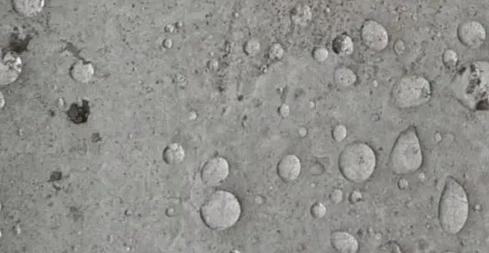

When applied to cement, tiles, or fabrics, the silicone waterproof agent spreads evenly and penetrates into the pores and holes of the substrate.

Upon drying or curing, a transparent film forms on the surface, binding to mortar, concrete, or ceramics through chemical condensation reactions between silanol and hydroxyl groups.

At the microscopic level, methyl (-CH₃) groups orient toward the air, creating a hydrophobic barrier that repels water and moisture.

This film remains breathable, allowing trapped moisture to escape from inside walls or floors while preventing external soaking from rain or pools.

In underground engineering, such as basements, tunnels, or storage areas, the same mechanism ensures that concrete and bricks maintain strength and do not degrade due to water infiltration.

3. Processing & Application Guidelines

To achieve optimal waterproof performance, the formulation and application process must be precisely controlled.

(1) Concentration & Mixing: For cement mortar or gypsum products, dilute the silicone waterproofing emulsion with water before mixing it into the base materials.

(2) Surface Preparation: Ensure the surface is clean and free of oil, dust, or loose particles. Avoid contact with wet substrates before application to prevent uneven curing.

(3) Application Methods: The product can be applied by spraying, brushing, or soaking, depending on the materials. For large construction surfaces such as walls, floors, or roof tiles, spraying is convenient and provides uniform coverage.

(4) Curing Conditions: Allow the film to dry at room temperature or under moderate heat. Avoid direct sunlight or strong airflow to maintain a smooth, transparent finish.

(5) Compatibility: The agent can be safely used on ceramic tiles, cement, bricks, wood, and metal, as well as fabrics and adhesives used in roofing or bathroom sealing.

The result is a durable, moisture-proof, long-lasting coating that helps protect building materials in indoor and outdoor environments.

4. Physical and Chemical Characteristics

A typical silicone waterproofing emulsion appears light yellow or colorless, with medium viscosity and good fluidity for brushing or spraying.

It exhibits strong adhesion to cement, concrete, and ceramics, and maintains excellent waterproof performance even under heat or low temperatures.

Particle size distribution ensures deep penetration into pores and cracks in tiles, mortar, and plasterboard, forming a continuous, flexible layer that remains transparent after curing.

The resulting coating is moisture-proof, breathable, and provides effective protection against rain, soaking, and chemicals.

Even after extended storage or multiple wash cycles (for fabrics), the silicone waterproof agent maintains its form and does not separate or lose performance.

5. What are the applications across industries?

(1) Construction and Building Materials:

Silicone waterproof agents are widely used to protect cement mortar, roof tiles, floor tiles, gypsum products, and bricks in modern construction. They enhance service life, prevent shrinkage, and reduce repair frequency.

(2) Underground Engineering and Basements:

Ideal for underground or storage environments exposed to moisture or soaking. The film prevents water infiltration while maintaining breathability to avoid trapped vapor.

(3) Antique Buildings and Cultural Restoration:

The transparent, colorless form of silicone waterproofing makes it suitable for antique buildings or historical ceramics, ensuring no change in surface color or texture while providing protection from rain and moisture.

(4) Household and Industrial Uses:

In bathrooms, pools, roofing, and indoor floors, silicone-based sealants and adhesives help repair cracks and seal holes. The same materials are used to maintain fabrics, plasterboard, and perlite composites for heat and moisture resistance.

6. Safety, Storage, and Handling

Always avoid contact with skin, eyes, and open wounds. During transportation and storage, keep containers sealed and stored in a light-proof, cool, and dry place.

Silicone waterproof emulsions are generally non-toxic, but contact with chemicals or oil should be avoided to prevent contamination.

In case of low temperatures, warm the product gently before use to restore fluidity. The silicone sealant should never be mixed with strongly alkaline substances unless designed for cement integration.

With proper handling, the service life of the stored product can exceed 12 months, ensuring stable performance and convenient use for all construction scenarios.

7. How to make your waterproof perform better?

Silicone waterproof agents and sealants represent the next generation of waterproofing agents for both textiles and building materials.

Their ability to penetrate, protect, and maintain surfaces such as cement, ceramics, tiles, and fabrics makes them essential in modern construction and renovation projects. By combining durability, moisture-proof protection, and long-lasting performance, these materials help enhance the beauty and stability of structures in all environments — from underground engineering to roofing and indoor design. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone waterproof field and support the provision of diversified customized solutions.