Silicone coatings for automotive applications are widely recognized as a reliable and high-performance solution for protecting metal surfaces and components exposed to extreme heat, harsh chemicals, and demanding environmental conditions. As automotive technology evolves, manufacturers increasingly rely on silicone materials and silicone polymers to provide superior protection, long-term durability, and stable performance under high temperatures.

From exhaust systems and engine components to electrical insulation and composite structures, silicone coating systems offer a unique combination of heat resistance, flexibility, adhesion, and environmental stability that traditional coatings struggle to maintain.

- Why Silicone Coatings Are Ideal for the Automotive Industry

- Processing Advantages and Curing Options

- Typical Automotive Silicone Coating Applications

- Benefits for Automotive Manufacturers

- How to make your coatings products better?

1. Why Silicone Coatings Are Ideal for the Automotive Industry

(1)Outstanding Heat and Temperature Resistance

One of the most critical advantages of HT silicone coating technology is its ability to withstand extreme temperatures and repeated heat cycling without cracking, peeling, or losing adhesion.

Silicone coatings are commonly used on:

- Exhaust systems and titanium exhaust wrap

- Exhaust wraps reinforced with glass fiber

- Engine parts are exposed to continuous heat dissipation

- Surfaces operating under extreme heat and thermal shock

Thanks to their low modulus and high tolerance for thermal expansion, silicone coatings maintain performance where conventional organic coatings fail.

(2)Reliable Protection in Harsh Environments

Automotive components are exposed to oil, moisture, chemicals, vibration, and corrosion. Silicone rubber–based coatings and silicone coating formulations provide:

Excellent water repellency

Strong resistance to oils and automotive chemicals

Long-term corrosion protection

Stable performance under fluctuating environmental conditions

These properties ensure reliable protection and help automotive manufacturers extend component service life, even in harsh environments.

(3)Superior Adhesion to Metals and Complex Surfaces

Advanced silicone polymers are engineered to deliver excellent adhesion to a wide range of metals, plastics, and composites. This makes silicone coatings suitable for

Engine housings and structural parts

Surfaces exposed to heat and vibration

Multi-material assemblies requiring flexible sealing

Silicone coatings can be applied by spray, dip coating, or through automatic dispensing equipment, offering flexibility for modern production lines and design engineering requirements.

(4)Flexible, Durable, and Crack-Resistant Performance

Unlike rigid coatings, silicone systems remain flexible after curing. This flexibility allows them to:

Act as protective seal layers

Accommodate movement between joined components

Maintain adhesion during repeated thermal and mechanical stress

These properties are particularly valuable in automotive applications where vibration, expansion, and contraction are unavoidable.

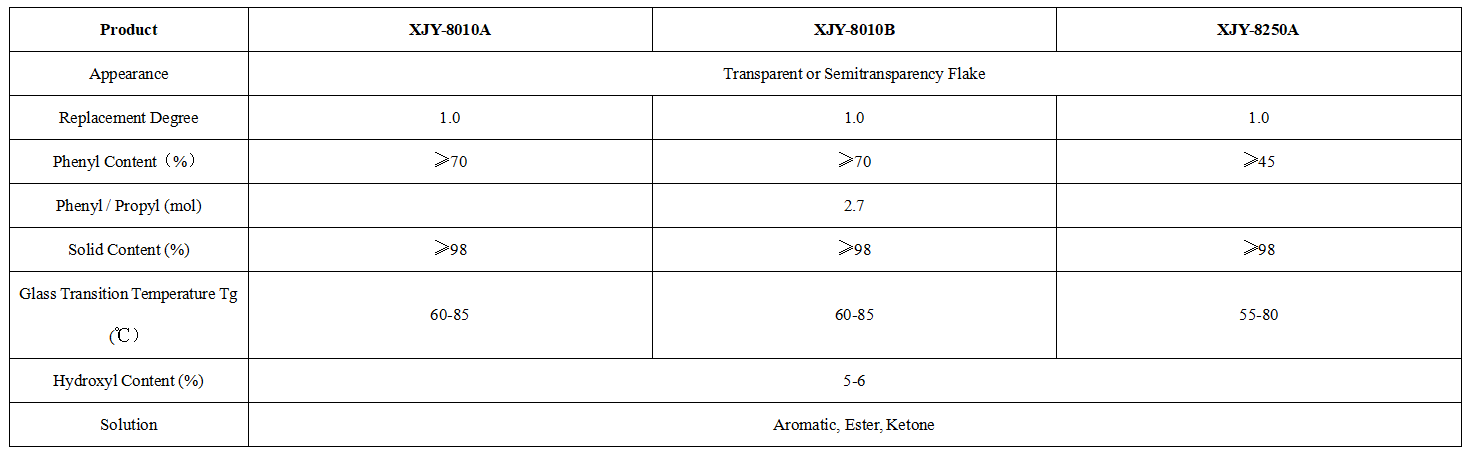

XJY-8010A/B/8250A Methyl Phenyl Silicone Resin

Methyl phenyl silicone resin can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat resistance, which hardly decomposes at 200℃ or even higher temperatures, and can be used to prepare all kinds of heat-resistant coatings, with heat-resistant insulation grade up to H class. Silicone resins have excellent weathering and UV resistance and can be used for powder and liquid coatings. Silicone resins have excellent weather resistance and provide all-around protection for equipment. Silicone resins have excellent weatherability and good adhesion. Silicone thin layers also have excellent weather resistance, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties.

2. Processing Advantages and Curing Options

(1)Fast Cure and Heat Curing Compatibility

Most automotive silicone coatings are designed for heat curing, offering:

Fast cure cycles

Compatibility with high-throughput manufacturing

Uniform film formation across complex geometries

Depending on performance requirements, coatings may be applied in three coats, with each next coat building enhanced durability, insulation, and surface protection.

(2)Compatibility with Advanced Automotive Technologies

Originally developed for high-temperature industrial use, silicone coatings have evolved into innovative solutions for modern automotive systems, including:

Electrical insulation and encapsulation

Optical bonding in sensor and lighting systems

Adhesion layers for gaskets, adhesives, and sealing materials

Their stable physical properties ensure consistent performance across a wide temperature range.

3. Typical Automotive Silicone Coating Applications

Silicone coatings are widely used in:

Automotive exhaust systems and exhaust wraps

High-temperature engine components

Metal and composite parts requiring heat resistance

Electrical insulation and protective encapsulation

Flexible sealing, bonding, and protective layers

Functional coatings combining aesthetic appeal with protection

4. Benefits for Automotive Manufacturers

For automotive manufacturers and material suppliers, silicone coatings offer clear advantages:

Maintain performance at high temperatures

Provide long-term durability and reliability

Reduce maintenance and replacement costs

Support lightweighting and advanced materials

Enable advanced formulations tailored to specific applications

5. How to make your coatings products better?

Silicone coatings for automotive use deliver a rare balance of temperature resistance, adhesion, flexibility, and durability. Whether applied to metal surfaces, exhaust components, or complex assemblies, silicone coating systems provide superior protection under extreme operating conditions.

As automotive materials continue to advance, silicone coatings remain a proven and future-ready solution for protecting components, enhancing performance, and meeting the demanding standards of the global automotive industry.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone cosmetics field and support the provision of diversified customized solutions.