With the rapid development of silicone optics, optical silicone materials are increasingly used in a wide range of optical and lighting applications.

Compared with traditional plastics, polycarbonate (PC), and glass, optically clear silicone offers a unique combination of optical performance, durability, and design freedom.

- Optical Clarity and Optical Properties

- Wide Operating Temperature Range and Dimensional Stability

- Design Freedom and Moldability

- Lightweight, Flexible, and Durable Performance

- Medical and Contact Optical Applications

- Material Stability and Long-Term Performance

- From Prototype to Production

- Why choose XJY Silicone?

1. Optical Clarity and Optical Properties

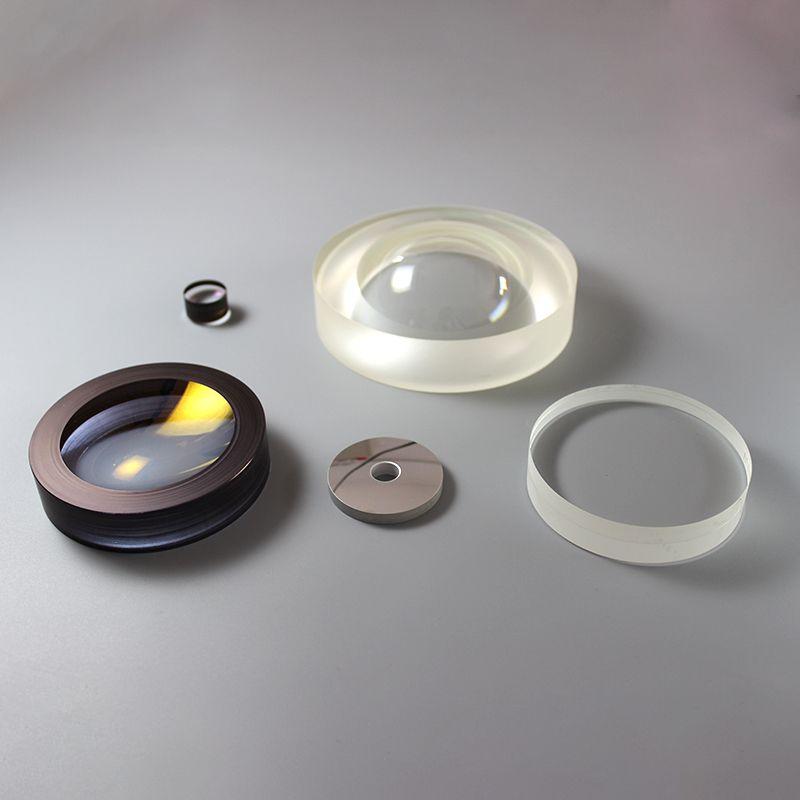

Optically clear silicone is known for its excellent optical properties, delivering high clarity, high purity, and low haze. In many LED applications, lenses, and light pipes, silicone maintains long-term transparency and shows a reduced likelihood of yellowing or losing optical performance.

Unlike some other materials, silicone does not easily lose transparency under prolonged exposure to UV, heat, or harsh environmental conditions, making it highly suitable for demanding lighting and optical silicone systems.

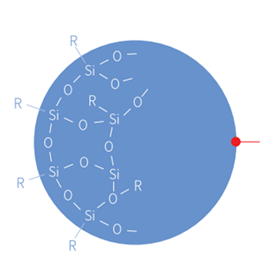

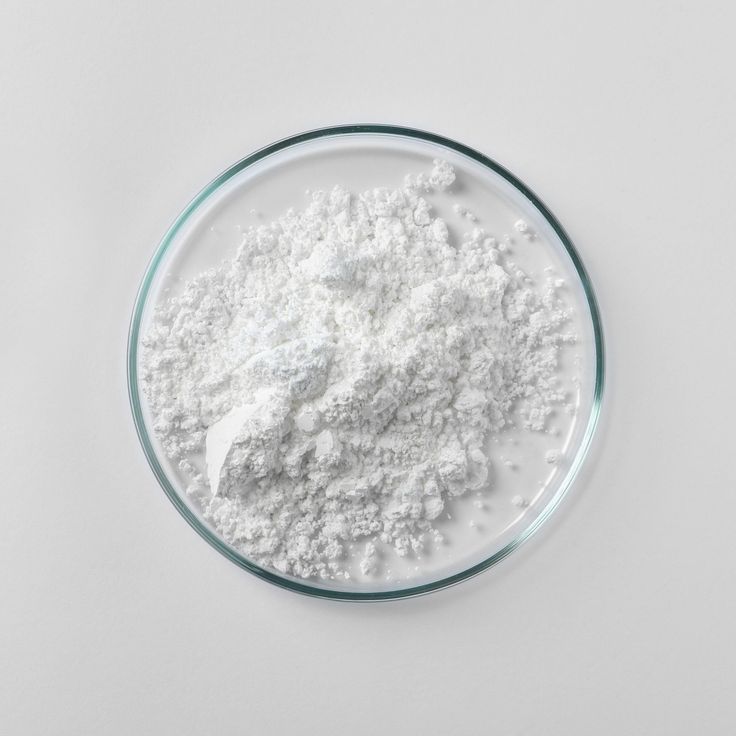

XJY-801 Polymethylsilsesquioxane (Spherical Silicone Resin Powder) can be widely used in high-end transparent PC lamps, lampshades, lightboxes, flat-panel LCD light diffuser plates, etc.

2. Wide Operating Temperature Range and Dimensional Stability

One of the key advantages of silicone optics is their wide operating temperature range. Optical silicone materials maintain excellent dimensional stability across extreme temperature conditions, minimizing deformation and internal stresses during operation.

This property is especially valuable in compact devices, LEDs, and optical assemblies, where thermal cycling can negatively affect optical alignment and system performance.

3. Design Freedom and Moldability

Compared with rigid glass or thermoplastic plastics, optical liquid silicone rubber offers significantly greater design freedom. Thanks to its low viscosity, silicone can easily fill complex mold geometries, allowing the replication of fine features, small undercuts, and even negative draft angles.

Designers can create parts with thicker walls, complex surface structures, and integrated optical functions, reducing design challenges while improving overall function.

4. Lightweight, Flexible, and Durable Performance

Silicone optical components are significantly lighter than glass while remaining robust and flexible. They show excellent resistance to vibration, mechanical shock, and repeated thermal stress.

This combination of lightweight structure and long-term durability makes silicone ideal for LED applications, portable devices, and advanced lighting systems where reliability is critical.

5. Medical and Contact Optical Applications

In medical applications, optical silicone materials provide additional value due to their proven biocompatibility. Their soft surface, adjustable durometer, and controlled flexibility make them suitable for applications involving contact with the human body.

Silicone optics are also easy to keep clean, comfortable during use, and resistant to chemical and environmental degradation, which is essential in healthcare environments.

6. Material Stability and Long-Term Performance

Silicone materials demonstrate strong resistance to aging, chemicals, and environmental exposure. Their optical and mechanical properties remain stable over time, even in harsh UV, high-heat, or high-humidity conditions.

This stability ensures reliable performance in long-life optical applications, reducing maintenance needs and extending product lifespan.

7. From Prototype to Production

Optical silicone materials are well-suited for both prototype development and mass production. Their ease of making, adaptability to different sizes, and compatibility with automated assembly processes simplify the transition from concept to finished product.

For engineering teams and material designers, silicone offers an ideal balance between manufacturability and advanced optical performance.

As optical systems continue to evolve toward higher integration, smaller form factors, and enhanced durability, silicone optics will play an increasingly important role. Their combination of optical clarity, flexibility, heat resistance, and long-term stability makes them a valuable material choice for future optical silicone, lighting, and medical device designs.

8. Why choose XJY Silicone?

With continuous research and material innovation, silicone resins and elastomers are expected to further expand their role across a broader range of high-performance optical applications.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone cosmetics field and support the provision of diversified customized solutions.

![]()