A pressure-sensitive adhesive (PSA) is designed to bond on contact with light pressure, enabling fast bonding without a complex process. In the market today, PSAs are widely used in tapes, labels, protective films, and many industrial applications, including electronics, automotive, and healthcare.

When engineers compare silicone pressure-sensitive adhesive systems with acrylic pressure-sensitive adhesive systems, the decision often comes down to performance needs: operating temperature, surface energy of the substrates, clean removability, and long-term reliability (including shelf life and resistance to the environment).

As a silicone resin manufacturer, we provide silicone resin and silicone additive options designed to upgrade adhesive properties in advanced PSA systems.

- Silicone PSAs vs Acrylic PSAs: What’s the Key Difference?

- Why Silicone Additives (Including Silicone Resin) Are Used in PSA Formulations

- Application Advantages: Where Silicone Pressure Sensitive Adhesive Wins

- Coating & Processing Notes (Without Going Into Lab Details)

- Trade-Offs to Expect: Balancing Tack, Adhesion, and Cohesive Strength

- How to Choose the Right Silicone PSA?

1 Silicone PSAs vs Acrylic PSAs: What’s the Key Difference?

Silicone PSAs are built on a flexible polysiloxane backbone (Si–O–Si), which is known for stability across wide temperatures and strong resistance to harsh conditions such as moisture and sunlight exposure.

By contrast, acrylic PSA systems can offer good performance at a lower cost for many general uses, but silicone-based PSAs are often selected when the application demands:

Higher operating temperature limits

Better performance on low-energy surfaces

Strong, clean removability (easy to remove with minimal residue)

Reliable performance on specialty plastic films and challenging substrates

In short, acrylic can be a great baseline; silicone becomes the upgrade path when requirements are strict.

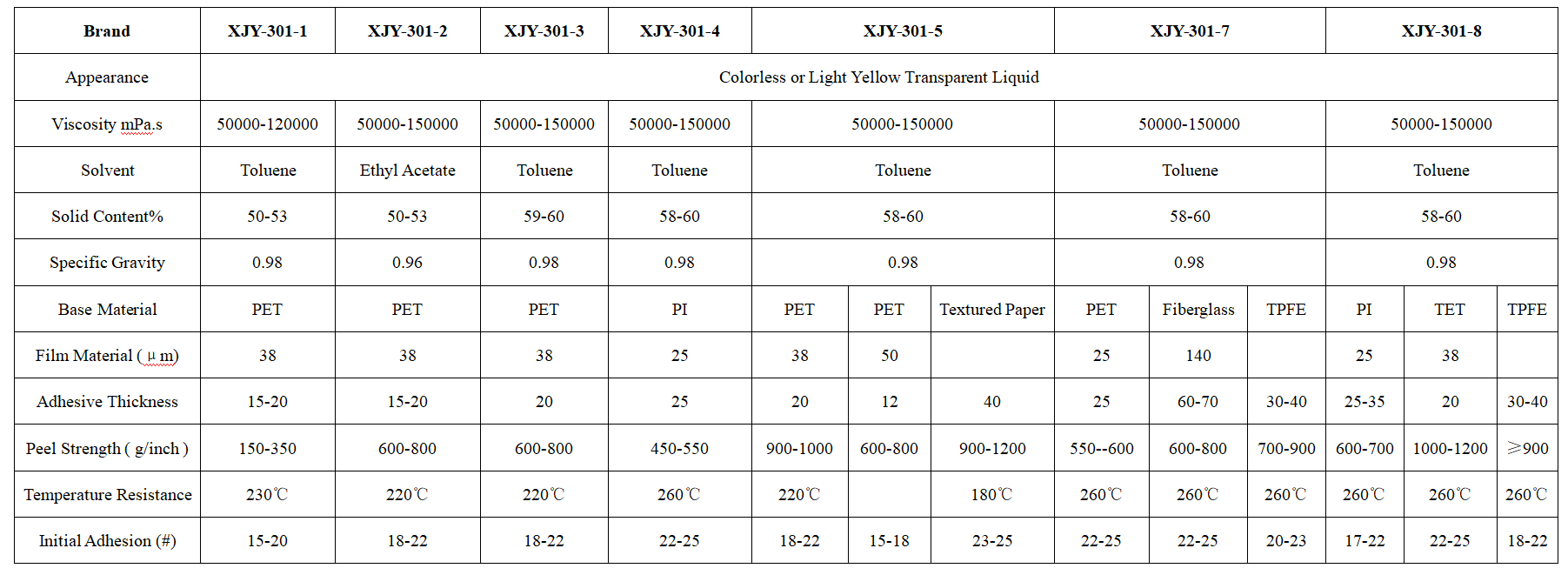

XJY-301 Silicone pressure-sensitive adhesives

It is made from the specific structure of silicone resin and high molecular weight polydimethylsiloxane in cooperation with organic adhesive, which is suitable for specific scene conditions.

Compared with natural rubber, it is characterized by heat resistance, high stability, good electric insulation, good transparency, high peel adhesion, and chemical resistance, etc. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care, and mica tapes, splicing tapes, protective films, and other fields.

2 Why Silicone Additives (Including Silicone Resin) Are Used in PSA Formulations

Even within silicone PSA systems, manufacturers may add silicone additives to tune performance. In practical manufacture, the goal is to achieve a balanced set of properties:

Adhesive strength (often measured as peel/adhesion)

Cohesive strength/cohesion strength (internal strength to resist creep)

Tack (instant stick)

Processing window and shelf life (stable viscosity and handling over time)

Thermal and environmental resistance

Silicone resin or silicone-based additive packages can be designed to reduce shrinkage, stabilize coating behavior, and improve heat resistance, depending on the PSA system and the required performance target.

3 Application Advantages: Where Silicone Pressure Sensitive Adhesive Wins

A) Low-energy surfaces and difficult substrates

Many PSAs struggle to wet out and anchor on low-energy surfaces. Silicone PSAs are often selected to improve anchorage and adherence on difficult substrates, including selected plastics and release-sensitive surfaces.

B) High operating temperature range

For high-temperature masking, insulation, and process tapes, the operating temperature window is a make-or-break KPI. Silicone PSA systems are commonly formulated to meet demanding high-temperature requirements better than standard acrylic systems.

C) Clean removability for films, displays, and protection

In applications like protective films, displays, and optical components, clarity and clean removability matter. A silicone PSA can be formulated for reliable adhesion during use, then be removed cleanly, helping reduce rework and surface contamination risk.

D) Better environmental resistance (moisture, mildew, fungus)

For some environments, PSAs face humidity-driven performance loss, plus biological issues like mildew or fungus on certain backings and surfaces. Silicone-based systems are often chosen where moisture resistance and long-term stability are crucial.

4 Coating & Processing Notes (Without Going Into Lab Details

In PSA tape production, the adhesive is typically coated onto a backing (for example, polyester films or other backings) and then dried/cured, depending on the system.

Depending on the production line and product positioning, silicone PSA can be formulated using different solvent strategies (including being diluted for coat-weight control). Some producers also evaluate aliphatic solvent routes as part of their process and compliance strategy.

Key point: manufacturing constraints (solvent management, viscosity stability, coat weight, cure schedule) should be considered early when selecting silicone resin/additive packages.

5 Trade-Offs to Expect: Balancing Tack, Adhesion, and Cohesive Strength

A practical rule in PSA development: improving one axis can shift another.

When silicone additive addition is used to push thermal resistance or dimensional stability, you may see changes in tack, adhesion, or peel behavior. That’s why a formulation must be set based on the end-use: substrate type, required clean removability, operating temperature, and targeted cohesive strength.

6 How to Choose the Silicone PSA?

When customers request a recommendation, we typically ask for:

- Target operating temperature and duration

- Substrate type (especially low-energy surfaces) and surface condition

- Target adhesion profile: tack, peel, and cohesive strength

- Backing type (e.g., polyester, plastic films, paper) and whether it is coated/treated

- Processing preference: solvent route, coat weight, cure approach, and shelf life requirements

- Any special needs: clarity for displays, moisture resistance, removability, or contamination control

- Based on these inputs, we can offer suitable silicone resin grades and additive options to meet the performance target.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone cosmetics field and support the provision of diversified customized solutions.

![]()