Among the wide variety of Silicone softeners, silicone additives have attracted more and more attention due to their unique surface properties and excellent softness. Now, most of the fabrics finished with Silicone softener are hydrophobic, which makes the wearer feel stuffy and difficult to wash. Many products often show demulsification and bleaching. The traditional hydrophilic polyether silicone oil has better hydrophilicity and water solubility, but its flexibility and finishing effect is poor in durability. Therefore, the development of a new type of hydrophilic Silicone softener with excellent flexibility and durability has strong practical significance.

![]()

It is suitable for the softness of natural fiber textiles such as cotton, wool, silk, hemp, and human hair.

Fabric Silicone softener has a wide range of applications in fabric finishing. Silicone softener can process not only natural fiber fabrics but also various synthetic fibers such as polyester and nylon. The treated fabric is anti-wrinkle, anti-fouling, anti-static, anti-pilling, plump, soft, elastic, and shiny, and has a smooth, cool, and firm style. Silicone softener can also increase the strength of the fiber and reduce wear. Silicone softener is a promising softener, and it is also an important additive to improve product quality and increase product added value in textile printing and dyeing.

![]()

![]()

![]()

XJY Silicones

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

We are manufacturing and customizing the raw material of the silicone softener, our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.

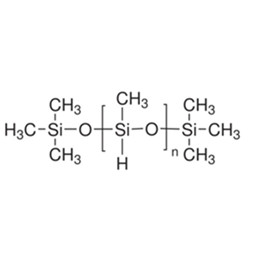

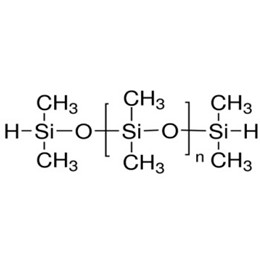

XJY-701 (Polymethylhydrosiloxane(PMHS)) and XJY-707(Hydride Terminated Polydimethylsiloxane(HPDMS)) can be applied to silicone softeners for synthetic fibers.

![]()