The history of human beings utilizing medical-grade materials is as long as the history of human beings. Since the beginning of mankind, people have been fighting against various diseases, and biomedical materials are one of the effective tools for mankind to fight against diseases. Medical grade silicone is a new environmentally friendly material in modern society, and is widely used in the medical field, so why choose medical silicone for the biomedical field?

Silicone material was a synthetic polymer introduced in the 1940s, its excellent performance is extremely good in many fields, such as medical grade silicone in the field of biomedical materials is very useful.

Silicone materials are chemically inert at room temperature, non-carcinogenic, hypoallergenic, and do not lose their mechanical properties when implanted over a long period. They have high stability in chemical and thermal degradation, which makes them suitable for a wide range of medical applications, such as bionic materials used for bone tissue regeneration, various types of catheters, breast forms, prosthetics, bioprostheses, synthetic skins, cardiac bypass machines, repair materials, stuffing materials, coatings, and so on. In addition, good blood compatibility also makes it possible to meet the needs of materials in contact with blood.

Here's some information about it:

- What are the properties of silicone?

- What are the preparation methods of silicone?

- How to apply silicone in the biomedical field?

- How to choose silicone raw material products?

- How to make silicone products?

1. What are the properties of silicone?

Silicone is an important material. The physical properties of silicone are determined by its molecular structure and chemical bonding.

The main chain of silicone consists of Si-O, and a variety of organic groups can be attached to the Si atom, such as methyl, amino, methoxy, etc. The molecular structure of the silicone structure and organic groups makes the silicone material both organic and inorganic materials and thus has excellent properties such as corrosion resistance, high and low-temperature resistance, non-toxic, hydrophobic, and physiologically inert.

Its main features are a certain degree of flexibility and a certain degree of elasticity, chemical stability, and thermal stability, and material changes can be easily controlled. The introduction of organic groups has greatly enriched the applications of silicone materials.

2. What are the preparation methods of silicone?

There are many ways to prepare silicones, including chemical synthesis, phase transfer catalysis, free radical polymerization, and flexible template methods.

3. How to apply silicones in the biomedical field?

Medical grade silicone materials mainly include in vitro applications, in vivo applications, and in the blood as a drug carrier in the field of medical applications.

Because hypoallergenic, non-toxic, biocompatible, and other characteristics of medical grade silicones, do not produce an allergic reaction with the skin in vitro applications and can be used as a substitute for the body's tissues and organs, auxiliary supplies for long-term or short-term retention in vitro application, for drugs also has a unique advantage in the blood as a carrier.

3.1 In vitro application

Because medical-grade silicone rubber has good tissue compatibility, and no cytotoxicity, its film dressings have better gas permeability, which means silicone materials can be used for in vitro wound dressings, medical silicone adhesive ( for high-strength elastic bonds), and so on.

Medical pressure-sensitive adhesives need to consider the problems that may arise after contact with the skin, such as skin irritation, skin sensitization, infection caused by bacterial growth, and so on. Silicone pressure-sensitive adhesive has a mild and stable long-lasting adhesion, is hypoallergenic, repeated use will not damage the skin, widely used in medical wound patches, elastic bandages, and medical tape.

![]()

![]()

Silicone resin is a highly cross-linked, both organic resin and inorganic material with dual characteristics of silicone materials, with excellent hydrophobicity and anti-sticking release properties, etc., and can be used as coatings, paints, etc. in biomedical equipment, surgical tools. Silicone surface coating on the surface of biomedical materials can form a thick layer of silicon oxide, this layer can control the chemical properties of the material surface to achieve good biocompatibility and anti-inflammatory properties.

3.2 In vivo applications

Medical-grade silicones can be used to improve the compressive strength and shock resistance of biomedical materials, thereby significantly improving the durability and reliability of biomedical materials. Medical-grade silicones can be used as materials for biomedical material scaffolds. High-consistency rubber has better performance in the high-strength molding process and extrusion processes. Silicone scaffold materials can provide a certain degree of mechanical strength support for the body's tissues while maintaining the appropriate elasticity and can be stable and safe to support and repair the body's internal vital organs and tissues.

Medical grade silicones are physically and chemically stable, with little reaction to tissues within the body, and can play a role in the body as a barrier, support, and provide a place for cell growth and adhesion, and are often used as short-term or long-term implants. For example, medical grade silicones elastomers have ideal biological properties for the flexible leaflets of fully synthetic heart valve replacements.

Thanks to the medical grade silicones implanted in the human body after the foreign body reaction, physiological inertia, and other characteristics, a considerable part of the silicone products are used as various types of catheters, which in the process of application to avoid the risk of bacterial infection.

![]()

3.3 In blood application

Silicone can be used as a biomedical material matrix material. Silicone materials have a high degree of biocompatibility and biofilm selectivity, can promote cell adhesion and proliferation, and also can control cell differentiation. As a matrix material, silicone can be used not only for bone repair but also as a biocompatible material for blood vessels, nerves, and other important tissues.

Silicone materials applied to blood, mostly using mesoporous silicon nanoparticles as a drug carrier placed in the body, subject to pH, light, ultrasound or redox reactions and other factors to achieve controlled release of drugs, or used in tumor therapy stimulus-responsive drug release, targeted drug delivery and so on.

The mechanism is that the organic functional groups in the silicone nanoparticles can induce surface polarity, by affecting the interaction between the carrier particles and drug molecules to achieve stimuli-responsive release and a high drug loading rate.

![]()

![]()

3.4 What are the precautions for medical silicone?

When used in vitro, it is necessary to consider whether the material will cause allergy and damage to human skin, and when in contact with wounds, it is also necessary to consider the permeability and antibacterial properties of the material.

Implants left in the body need to pay more attention to the material's biocompatibility, cytotoxicity, and antibacterial properties. Silicone materials have excellent biocompatibility and low toxicity with the human body, but if they are inadvertently contaminated during contact or if microorganisms accumulate during use, they can have a significant impact on the human body. Therefore, the development process focuses on the antimicrobial modification of the material.

Due to physiological inertia and excellent biocompatibility, silicone materials in biomedical use have a unique advantage that is difficult to replace, more and more products are being developed, from skin dressings, artificial joints, cochlear implants, to hydrocephalus drainage devices, artificial heart valves, catheters, and then to drug carriers, silicone materials are in a variety of forms of active guarding human health.

4. How to choose medical silicone raw material products?

XJY-8206 Powder Series Methyl Vinyl MQ Silicone Resin

It is a solid powder resin, this resin is used for additive molding silicone rubber reinforcing filler.

It can be used as the basic raw material of highly transparent and high-hardness silicone, with wear-resistant and weather-resistant, etc., and it is used to improve the performance of medical devices.

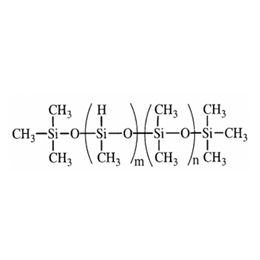

XJY-702 Methylhydrosiloxane/Dimethylsiloxane Copolymer

This product is non-toxic and tasteless, with active groups, under the action of catalysts, it can react with double bonds, radicals, and other groups, and is the basic raw material for water-soluble silicone oil and other products.

It can be used as a crosslinking agent for the production of additively molded liquid silicone rubber for medical devices.

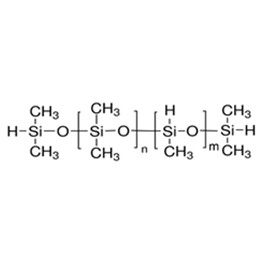

XJY-711 Hydride Terminated Methylhydrosiloxane/Dimethylsiloxane Copolymer

It can be used as a crosslinking agent for applied silicone rubber and liquid silicone rubber.

It is used in many medical devices, including seals for implantable or non-implantable devices, pistons, gaskets, and parts of electronic electronic devices( such as drug-eluting devices).

XJY-706 1,1,3,3-Tetramethyldisiloxane

It is soluble in many organic solvents such as aromatic hydrocarbons/petroleum hydrocarbons and insoluble in water, it is a kind of silicone intermediate with a wide range of uses.

Due to the molecular structure of the molecule containing active hydrogen atoms, it can be synthesized through the silicon-hydrogen addition reaction of the copolymer polymers, and from them can be made into pharmaceutical intermediates.

5. How to make silicone products?

With the continuous development of the application of biomedical materials, the application of silicone in the field of biomedical materials is also continuously expanding and deepening, with great potential for development and good technical prospects. Although there are still some technical difficulties and technical bottlenecks, these problems can be optimized and solved through in-depth research and technological innovation, thus promoting the wider and deeper application of silicone in the field of biomedical materials. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing method and experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the medical industry and support the provision of diversified customized solutions.