Waterproof agents are chemicals that prevent moisture penetration and can be applied to a variety of different materials such as textiles, wood, concrete, stone, and more. Waterproof agents work by forming a protective film that prevents water penetration, thus protecting the material from water erosion and damage. Silicone waterproof agents have excellent performance and are quite popular in the market, so why use silicone waterproofing agents?

Traditional waterproof agents have the disadvantages of temperature sensitivity, low tensile strength, and tensile rate, poor aging resistance, especially for exposed waterproofing projects, and extreme temperature characteristics are not good. the old sealant is easy to cause aging, dry cracks, deformation, fracture, rot, and other phenomena.

Silicone waterproof agent has impermeable performance and good durability, service life is up to 10 years or more(permanent waterproof); the waterproof membrane formed by the water-repellent is permeable layer, and its permeable pores than water molecules are smaller than the water vapor, and thus, the rain outside can not penetrate into and moisture indoor can be emitted; silicone waterproof agents coating is colorless and transparent, it painted on the surface of the building does not affect the color of the building.

Here’s some information about it:

- What are silicone waterproof agents?

- How to use silicone waterproof agents?

- What are the use methods of silicone waterproof agents?

- What are the precautions of silicone waterproof agents when used?

- How to make silicone waterproof agents?

1. What are silicone waterproof agents?

Silicone waterproofing agent is a non-polluting, non-irritating new efficient material, widely used in various countries as a clear silicone sealant. This is sprayed (or brushed) on the surface of the building, it can form a layer of colorless transparent, UV-resistant breathable film on its surface which is imperceptible to the naked eye when the rain blows on it or meets the humid air, the water droplets will naturally flow to prevent the intrusion of water, and at the same time it can also wash away the dust and soil on the surface of the building, which can play a role in making the inner wall moisture-proof, mildew-resistant, and protective seal, and so on.

![]()

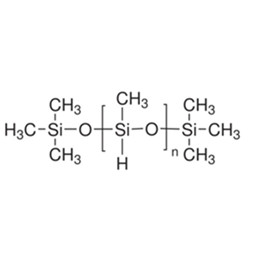

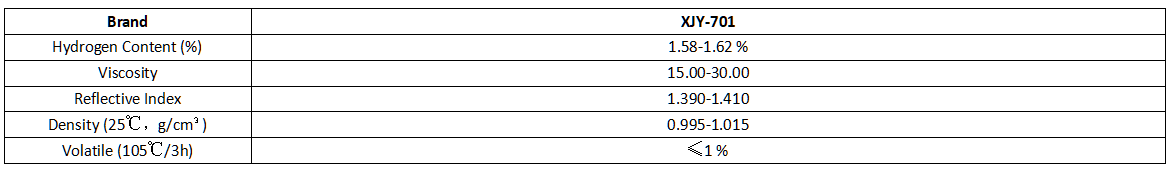

XJY-701-Polymethylhydrosiloxane

Under the action of a metal salt catalyst, it can be crosslinked into film at low temperatures to form a waterproof film on the surface of various materials, which can be used as a waterproof agent and apply sealant for various materials such as fabrics, cultured marble, glass, vinyl tile, ceramics, paper, leather, metal, cement, marble, galvanized metals and so on, especially waterproofing of fabrics.

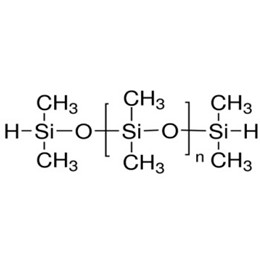

XJY-711 Hydride Terminal Methylhydrosiloxane/Dimethylsiloxane Copolymer

It can be used as a waterproof agent for fabrics and buildings.

XJY-8205 Methyl MQ Silicone Resin

It is a solid powdered resin that can provide excellent water resistance to form a long-lasting film, which can be used as a waterproof agent.

2. How to use silicone waterproof agents?

Silicone waterproof agent is a common waterproofing material, which has excellent waterproof performance and durability and is widely used in various fields. Such as the construction field: for roofs, walls, basements, bathrooms, kitchens, and other buildings treatment; the industrial field: for chemical plants, power plants, petrochemicals, textiles, paper, and other industrial facilities waterproofing treatment; the automotive field: for automobile body, engine, chassis and other parts of the waterproof treatment.

![]()

(1) Silicone waterproof agents are widely used in roofing, interior and exterior walls, weather stripping, floors, bathrooms(bath sealant), plumbing fixtures, kitchens, basements, and warehouses of waterproofing moisture, reinforced concrete structures to prevent penetration, repairing sinks; In the external wall surface to form a layer of breathable water-repellent film, like a transparent, breathable raincoat to the building, to prevent water from wetting, soaking into the wall, preventing the interior wall surface wet mold, black and peeling and other diseases. Because of this product's rocket head-like molecular structure, making it have excellent permeability, it can be used as a polished floor tiles antifouling agent, which has a good effect.

![]()

![]()

(2) For underground civil defense projects: such as culverts, bridges, dams, tunnels, large hydroelectric power stations, and water diversion projects to reduce water erosion and prevent weathering;

(3) For wood surface, to prevent wood cracking

(4) For a variety of pools: such as aquarium safe, swimming pools, clean water pools, sewage tanks, water towers, etc;

(5) For high water absorption inorganic aggregates: such as perlite boards, roof tiles, cement bricks, high-rise buildings, lightweight brick finishes, asbestos, fabrics, insulation materials, etc. impregnation, so that it has a significant waterproofing, moisture-proof effect.

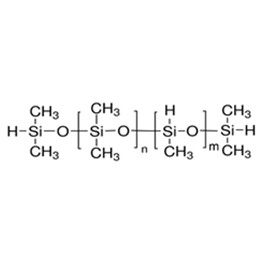

XJY-707 Hydride Terminated Polydimethylsiloxane

It can be used as a waterproof agent for natural and synthetic fiber fabrics.

(6) For water-soluble architectural coatings waterproofing, protection of color, prevention of pollution, and prevention of aging, has been widely used in exterior wall finishes;

(7) For latex paint, water glass, 107 glue additives, silicone waterproof agents can make it have obvious water, and can maintain stable bond strength;

(8) For oil drilling, can adjust the mud viscosity and density, can effectively prevent the drilling well collapse, and improve the drilling rate; used in oil wells in the late stage of the opening of the pump, injected into the oil recovery layer, to prevent the recovery layer of the crustal skeleton collapsed, so that far from the wells of the oil is more smoothly exploited;

![]()

![]()

(9) Silicone waterproof agent can be added to the proportion of 1-2% of the melted tarmac, which can increase the strength, and high-temperature resistance so that the road life extension.

(10) For architectural coatings. Further hydrolysis can produce methyl transparent resin coatings, and can also be mixed with 107 glue for embedded glue. At the same time, silicone waterproof agents can also be used for gypsum decorative materials fire treatment.

![]()

3. What are the use methods of silicone waterproof agents?

It can be sprayed and brushed directly, or added into cement mortar or concrete for use.

3.1 Spraying or brushing

In the concrete, mortar, precast concrete, and other surfaces are relatively rough parts of the project, with spraying is better; stone, marble, and other smooth surfaces of the project parts, can be brushed.

(1) The base surface should be cleaned carefully, and obvious cracks and holes should be repaired;

(2) Then it can use a low-pressure sprayer or rows of brush coated on the surface of the grass-roots level, spraying two times continuously, without intermission;

Note: The bottom surface should not be sprayed if it is too wet or if it is raining.

![]()

![]()

3.2 Adding cement mortar

(1) Clean up the base surface: First, it needs to clean up the grass-roots surface of oil, floating ash, and shedding layer.

(2) According to the weight ratio of 1:50 waterproof agent and cement, mix well waterproofing agent and the appropriate amount of water and then add cement and sand mixed into mortar use. Gray sand ratio control in 1:2.5-3 (32.5R grade above silicate cement, sand, mud content less than 3%), water-cement ratio ≤ 0.5. The waterproof layer is divided into two layers of construction (each layer 10mm thick). The bottom layer is first smeared with plain mortar 1mm, then smeared with a waterproof mortar layer, compacted at the beginning of condensation, rubbed with a wooden spatula into the hemp surface; smeared with the second layer of waterproofing mortar to catch the light, and compacted (such as decorative construction, must be rubbed into hemp surface). According to normal watering maintenance, the spraying cement maintenance agent effect is better.

3.3 Waterproof concrete

Sodium methyl silicone waterproof dose is 1% of the amount of cement, evenly mixed into the preparation of concrete, which is an ordinary concrete construction method. In order to ensure that the mix is uniform, the first silicone waterproofing agent and the concrete proportion of water are mixed evenly, and then cement, sand, and gravel.

![]()

![]()

4. What are the precautions of silicone waterproof agents when used?

(1) For winter construction: silicone waterproof agents can be used with sodium nitrite antifreeze.

(2) For general chemicals: construction workers should be careful not to splash the face in the storage and transportation and use, especially not splash into the eyes, or immediately rinse with plenty of water or ask a doctor to deal with it. They need to wear labor protection gloves, protective glasses, and good working clothes, to avoid contact with the skin.

![]()

![]()

(3) In the transportation and use of this agent, silicone waterproof agents shall not be in contact with zinc, aluminum, tin, and other more active metals, and can not be stored in ferrous metal containers in order to avoid chemical reactions caused by product deterioration and container corrosion.

(4) Pay attention to prevent rain, exposure, and packaging container damage during storage and transportation.

(5) Storage and transportation environment temperature is 0 ~ 30 ℃, and shelf life is three years.

5. How to make silicone waterproof agents?

Silicone waterproof agent has excellent waterproofing properties, and can ensure that the substrate is in a wet environment for a long time without damage, with good stability, high reliability, long-lasting effect, and so on; Silicone waterproofing agent can be waterproofing at the same time to maintain the respiratory properties of the substrate, which is very important for the waterproofing treatment of some building materials; Silicone waterproofing agent will not pose a threat to the environment, and will not release toxic substances to the human body. In addition, the use of silicone waterproofing agents will not cause discoloration or damage to the substrate, will not change the original nature of the substrate, and to protect the health of building materials is very favorable. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone material product can meet the needs of silicone water repellents and support the provision of diversified customized solutions.