UV-curable silicone resin is a versatile UV-curable resin system that hardens rapidly under UV light irradiation, offering a crystal clear appearance, low shrinkage, and excellent durability. Compared with conventional epoxy resin or standard UV resin, silicone-based UV cure resin systems combine fast UV curing speed with high heat resistance, flexibility, and long-term stability.

With growing demand for quick curing, low odor, and energy-efficient materials, UV-curable silicone resin has gained great importance in coatings, electronic devices, optical components, and small indoor projects requiring precise shape control and smooth surfaces.

- What Is UV-Curable Silicone Resin?

- Key Advantages of UV-Curable Silicone Resin

- Applications of UV-Curable Silicone Resin

- UV-Curable Silicone Resin vs. Epoxy UV Resin

- Why choose XJY Silicone?

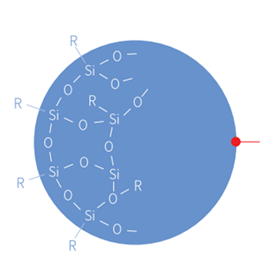

1. What Is UV-Curable Silicone Resin?

UV-curable silicone resin is a silicone-modified UV-curable resin that reacts and hardens when exposed to ultraviolet light. Unlike traditional thermally cured materials, this UV curable system enables fast curing without high-temperature processing, making it suitable for sensitive substrates such as glass, plastics, and electronic components.

Some advanced systems also feature secondary moisture cure, allowing deeper layers to harden completely, even when UV light penetration is limited. This helps overcome curing risks in thicker coatings or complex shapes.

2. Key Advantages of UV-Curable Silicone Resin

(1) Low Shrinkage and High Transparency

Compared with standard UV resin curing systems, UV-curable silicone resin exhibits low shrinkage and reduced internal stress. This minimizes cracking, brittleness, and bubble formation during curing. The material remains highly transparent and crystal clear, making it ideal for jewelry, optical parts, and protective coatings where appearance and surface quality matter.

(2) Fast UV Curing and Short Curing Time

Under UV light, the resin hardens within seconds to minutes, significantly reducing curing time and energy consumption. This quick-curing process improves production efficiency and is especially suitable for indoor use, small projects, and crafts that require fast turnaround and clean processing.

(3) High Heat Resistance and Temperature Stability

Thanks to the siloxane backbone, UV-curable silicone resin maintains performance across a wide temperature range, including low temperatures and elevated heat conditions. Compared with epoxy-based UV resins, silicone systems offer superior resistance to thermal aging, making them suitable for electronic devices and coatings exposed to heat during operation.

(4)Improved Flexibility and Tensile Strength

While many UV resins become hard and brittle after curing, silicone-modified systems provide a balanced combination of hardness, flexibility, and tensile strength. The cured resin forms a durable yet slightly soft structure that resists cracking under stress, vibration, or temperature changes.

(5) Excellent Adhesion and Surface Protection

UV-curable silicone resin delivers reliable adhesion to a wide range of substrates, including glass, metals, silicone rubber, and coated surfaces. Its low surface energy creates smooth, protective layers that resist moisture, chemicals, and environmental exposure. This makes it suitable for coating, bonding, and surface protection applications.

3. Applications of UV-Curable Silicone Resin

Coatings and Surface Finishing

UV-curable silicone resin is widely used in coatings where fast UV curing, durability, and smooth surface finish are required. Typical applications include protective coatings for indoor equipment, decorative surfaces, and functional layers that protect substrates from wear, moisture, and contamination.

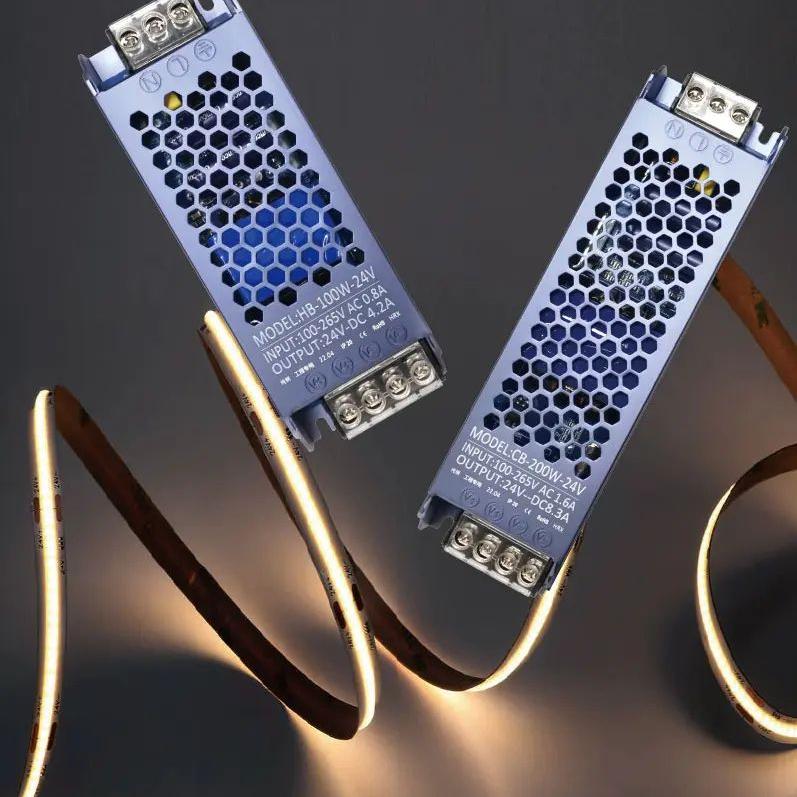

Electronics and Electrical Materials

In electronic devices, UV-curable silicone resin provides insulation, adhesion, and heat resistance. Its low viscosity allows easy coating and encapsulation of delicate components without damaging them during the curing process.

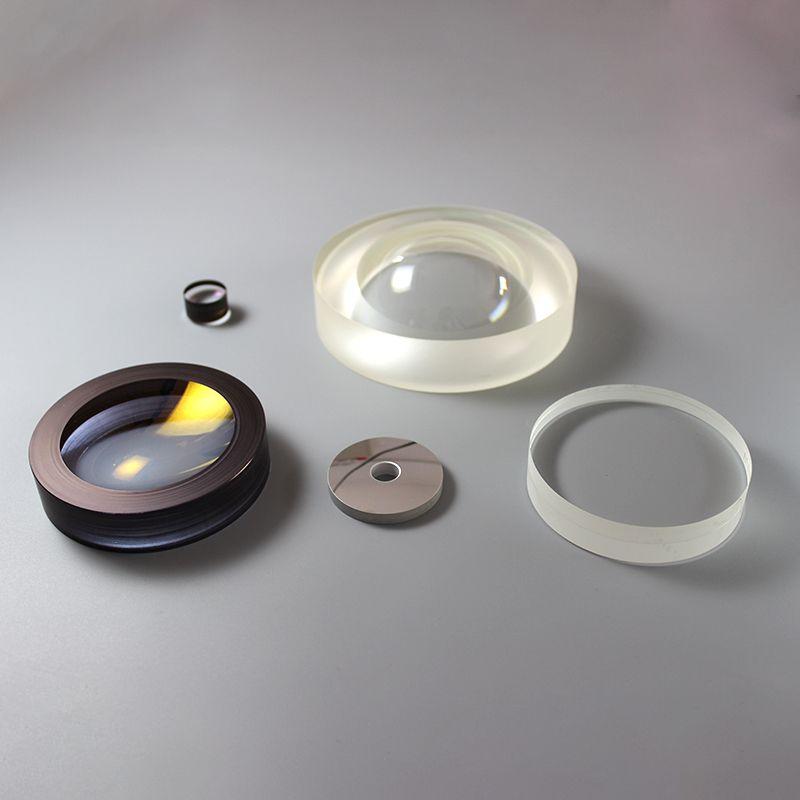

Optical, Jewelry, and Craft Applications

Due to its high transparency, low odor, and clean curing behavior, UV-curable silicone resin is commonly used in jewelry making, crafts, and decorative projects. The resin cures quickly under UV light, hardens evenly, and produces smooth, glass-like surfaces without excessive bubbles or stickiness.

4. UV-Curable Silicone Resin vs. Epoxy UV Resin

Compared with epoxy UV resin systems, UV-curable silicone resin offers:

Lower shrinkage and reduced internal stress

Better flexibility and resistance to brittleness

Higher heat resistance and durability

Improved performance under long-term UV exposure

These advantages make silicone-based UV resins a more robust solution for demanding applications where quality, stability, and long service life are required.

5. Why choose XJY Silicone?

UV-curable silicone resin represents an advanced UV-cure resin technology that combines fast UV curing, high transparency, low shrinkage, and excellent heat resistance. Its versatility makes it suitable for coatings, electronic devices, optical components, jewelry, and indoor applications requiring quick curing and durable performance.

As UV curing technology continues to develop, UV-curable silicone resin is expected to play an increasingly important role in modern materials systems, offering reliable solutions across a wide range of industries.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone optical field and support the provision of diversified customized solutions.