The silicone softener is an emulsion or microemulsion of polysiloxane and its derivatives, which can make the fabric have a good soft and smooth hand feeling. The products include emulsion polymerization, polymer silicone oil emulsification, and production processes such as modification and compounding, which have basically formed a system. But the application effect and performance are very different.

![]()

The main varieties of fabric silicone softeners are divided into the following categories according to the functional groups contained in the chemical structure.

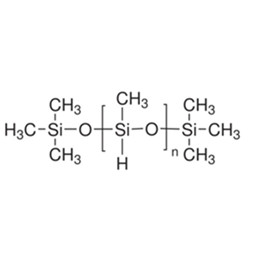

1. Dimethyl Silicone Emulsion:

This is the first product used in all kinds of silicone softeners. The relative molecular mass of silicone oil used as a softener is generally 60,000-70,000. It can give the fabric a slippery, firm and cool hand feeling, reduce the friction coefficient of the fabric, and improve the abrasion resistance and seamability of the fabric. However, it has worse washing durability and limited improvement in elasticity.

![]()

2. Hydroxy Silicone Emulsion:

This is the most widely used silicone softener in the 1980s. Its relative molecular mass is generally 60,000-80,000. The larger the relative molecular mass, the better the softness and smoothness. Because of its molecular chain end and Hong group end-capped, under the action of crosslinking agent and catalyst, it can crosslink with the reactive base of the fiber or itself to form a certain elastic polymer film, so it is washable. And can improve the elasticity of the fabric. The emulsion stability of silicone hydroxyemulsion softeners is also an important index to evaluate its quality.

![]()

3. Hydrophilic Soluble Silicone (polyether hydrophilic silicone):

This kind of silicone softeners is usually polyether and epoxy-modified polysiloxane. The appearance is a colorless and transparent thick liquid, which can give fabrics good moisture absorption, air permeability and antistatic properties. It can be mixed with various additives. In addition to resin finishing and soft finishing, it is also widely used in the paint dyeing process. It can not only improve the feel of the fabric due to the adhesive, but also improve the shortcomings of the adhesive roller.

![]()

![]()

4. Amino Modified Silicone:

The introduction of amino groups into the macromolecular chain of polysiloxane can greatly improve the performance of organosilicon. The introduction of amino groups can not only form firm orientation and adsorption with fibers, reduce the friction coefficient between fibers, but also chemically react with epoxy groups, carboxyl groups, and hydroxyl groups, so it can be applied to cotton, wool, silk, viscose, fiber, polyester, nylon, acrylic and other fibers and their blended fabrics. After finishing the fabric, it can obtain excellent softness and resilience, and its hand feel is soft and plump, smooth and delicate. Generally speaking, the higher the amino content, the better the softness. But higher amino content is also easier to cause yellowing.

![]()

5. Hydroxyamino Emulsion Polymerization Silicone Oil Emulsion

This type of silicone softener has an active ingredient of hydroxyamino-modified silicone oil. After commercialization, it is a blue translucent emulsion that is easily soluble in water and is mainly used for the smoothing and finishing of various fibers and fabrics. It has a good feel, and it is easy to cause oil drift and sticky rollers if used carelessly. It still needs improvement in terms of high-temperature resistance, high shear resistance, electrolyte resistance, and cationic chemical resistance.

![]()

6. High-concentration silicone softener

such as mixed silicone oil emulsion is represented, and its effective ingredients are amino-modified silicone oil, hydroxy silicone oil, silicone resin, etc. After commercialization, it is a white emulsion with giant particles, which is easily dispersed in water and is mainly used for the soft and smooth finishing of various fibers and garments. It feels good, but it still needs improvement in terms of storage stability, shear resistance, high electrolyte resistance and high-temperature resistance.

![]()

7. Linear polyether amino-modified silicone oil

This kind of silicone softener, its active ingredient is polyether amino-modified linear silicone oil. After commercialization, it can be a transparent liquid, easily soluble in water, and is mainly used for the soft and smooth finishing of various fibers and fabrics. It feels good and is excellent in high-temperature resistance, high shear resistance, electrolyte resistance, etc., but the use cost is relatively high.

![]()

Silicone softeners are now developing rapidly, with more and more varieties, and their prices have fallen. The number of applications using silicone softeners has increased significantly. In addition to the various types of silicone softeners mentioned above, there are also silicone softeners such as epoxy modification, amide modification, and carboxyl modification.

XJY Silicones

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

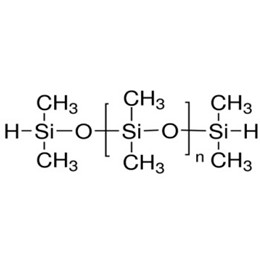

We are manufacturing and customizing XJY-701(Polymethylhydrosiloxane), XJY-707(Hydride Terminated Polydimethylsiloxane) in silicone softener, our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.

![]()