With the continuous progress and development of science and technology. People's demand for industrial materials also continues to rise. As a breakthrough material, photoelectric materials have received extensive attention and research. In such a background, silicone material is also gradually integrated into the field of optoelectronics materials and has become one of the hot spots of research from electrical to optical. What are the applications of silicone material in optoelectronics?

Silicones can form a variety of different chemical bonds so that a variety of silicone materials with different structures and properties can be designed, such as silicone rubbers, liquid silicone rubber, silicone oils, and so on.

Silicones are used in a wide range of applications and have unique optical properties, mainly due to the structural interactions between their silicon atoms and organic molecules, resulting in changes in the energy bands, and thus optical properties. Silicone can be prepared more easily, processing methods are convenient, and it can be used as a light-emitting material in optoelectronic devices, for example of optoelectronic devices consist of display screens; silicone has a variety of applications in emitting devices, such as solar power generation as an photovoltaic material; silicone can also be used in optical communications, and the use of silicon photovoltaic technology instead of traditional communications. Silicone is an important part of the research and development of optoelectronic materials.

Here’s some information about it:

- What is the structure of silicone?

- What are the performances of silicone?

- How to apply silicone in optoelectronic display devices?

- How to apply silicone in solar power generation?

- How to apply silicone in optical communication?

- How to choose silicone raw materials?

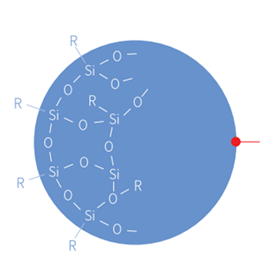

1. What is the structure of silicone?

Silicone material has a unique structure:

(1) Sufficient methyl groups on the Si atom shield the high-energy Polysiloxane main chain;

(2) C-H is unpolarized, making the intermolecular interaction force very weak;

(3) The Si-O bond length is long and the Si-O-Si bond angle is large.

(4) A Si-O bond is a covalent bond with 50% of the characteristics of an ionic bond (a covalent bond has directionality, the ionic bond has no directionality).

The basic structural unit of silicone product is composed of silicon-oxygen chain links, and the side chains are connected to various other organic groups through silicon atoms. Therefore, the structure of silicone products contains both "organic groups" and "inorganic structure", this special composition and molecular structure makes it a combination of organic properties and inorganic functions.

![]()

2. What are the performances of silicone?

Compared with other polymer materials, the most outstanding properties of silicone products are:

2.1 Temperature resistance properties

Silicone product (such as silicone rubber) have silicon-oxygen (Si-O) bond as the main chain structure, C-C bond energy of 82.6 kcal/g molecule, and Si-O bond energy in the silicone 121 kcal/g molecule, so the thermal stability of silicone product is high and the chemical bonds of molecules do not break or decompose under high temperature (or radiation exposure). Silicone can not only withstand high temperatures but also withstand low temperatures. It can be used in a wide temperature range. Whether it is chemical properties or physical and mechanical properties the temperature change is very small. So generally liquid silicone rubber can be used in most injection moulding machines.

2.2 Weather resistance

The main chain of silicone product is -Si-O-, which has no double bond, so it is not easy to decompose by ultraviolet light and ozone. Silicone has better thermal stability than other polymer materials, as well as irradiation and weather resistance. The service life of silicone rubber in the natural environment can reach several decades than natural rubber.

2.3 Electrical Insulation Properties

Silicone product has good electrical insulation properties, dielectric loss, voltage resistance, arc resistance, corona resistance, volume resistance coefficient, surface resistance coefficient, etc. are among the top insulating electronic materials, and their electrical properties by the temperature and frequency of the impact is very small.

Therefore, they are a stable electrical insulating material and are widely used in the electronic and electrical industries. In addition to excellent heat resistance, silicone also has excellent water repellency, which is the use of electronic devices in wet conditions with a high-reliability guarantee.

2.4 Biological Properties

Bioactive silicone is an essential nutrient for the human body. Silicone is an important element in the composition of human tissue and metabolism.

It is present in every cell of the human body and serves as a support for cell construction and helps in the absorption of other important substances such as magnesium, phosphorus, calcium, etc.

2.5 Low surface tension and surface energy

The main chain of silicone is very smooth, and its intermolecular force is much weaker than hydrocarbons, so it has a lower viscosity than hydrocarbons of the same molecular weight, weaker surface tension, smaller surface energy, and stronger film-forming ability.

This low surface tension and low surface energy is the main reason why it has been applied in many ways: hydrophobic, defoaming, foam stabilization, anti-sticky, lubrication, varnish and other excellent properties.

3. How to apply silicone in optoelectronic display devices?

Silicone has a high luminous efficiency and purity, it can be used as a light-emitting material in OLED devices, OLED devices have a very high brightness and color reproduction, but also can have low energy consumption. Currently, OLED technology is used in the main screen of cell phones, flat panels of medical devices, and TVs on the market.

Silicon-based OLED is a new type of OLED technology that utilizes a silicon-based substrate compared to traditional OLED technology, making the manufacturing process simpler and less costly. Silicon-based OLED technology is expected to become an important new display technology in the future, applied to smartphones, TVs, wearable devices, and other fields.

In addition, silicone can also be applied to optical components' material for LCD backlighting. In the traditional cold cathode fluorescent lamp liquid crystal displays, the yellow phosphor yellows, making the entire screen color degradation, and energy efficiency is not high. Silicone can directly emit light, thus reducing the electrical energy consumption of the entire LCD, and the color effect is more vivid.

XJY-801 Polymethylsilsesquioxane ( Spherical Silicone Resin Powder)

It has a light refractive index different from that of the base material. Inside the diffusion material with spherical silicone resin, light from a single direction can be diffused in all directions. Light diffusers can be made for flat panel LCD/PS light diffusers.

3.1 Why use silicon-based OLED technology?

The advantages of silicon-based OLED technology include the following:

(1) Low cost

Traditional OLED technology requires the use of an expensive glass substrate, while silicon-based OLED technology uses a common silicon substrate, which is much lower in cost.

(2) Simple production process

The production process of silicon-based OLED technology is simpler than traditional OLED technology, and the manufacturing process is easier to control.

(3) Higher stability and reliability

Silicon-based OLED technology can provide higher stability and reliability because the silicon-based substrate has better mechanical properties.

(4) Miniaturization possible

Silicon-based OLED technology can realize smaller pixel size and higher pixel density, which is expected to be applied to micro-displays and other miniature optoelectronic devices.

![]()

4. How to apply silicone in solar power generation?

The solar cell is a technology that people convert light energy into electricity by utilizing solar energy. Silicone can be made into transparent electrodes and used in organic solar cells as a photovoltaic material. Due to their flexibility and transparency, organic solar cells can be used in a variety of complex devices, such as mobile power, wearable electronics, and so on.

4.1 How to choose silicone materials in solar power generation?

(1) In the solar thermal power generation system:

According to use and form, silicone materials have these applications in the solar thermal power generation system: Silicone oil as a high-temperature heat transfer medium for solar thermal power generation systems; Heat-resistant and weather-resistant silicone coatings for solar photovoltaic power generation structures; Silicone materials for molding of Fresnel lens for solar thermal power generation

(2) In the solar cell system supporting:

According to use and form, silicones have these applications in the solar cell system supporting: One-component room-temperature vulcanized silicone rubber as a photovoltaic material; Solar cell chip surface reflection-reducing film materials; Protective film on the light-transmitting surface of solar cell modules; Filling and bonding materials for solar cell module assembly

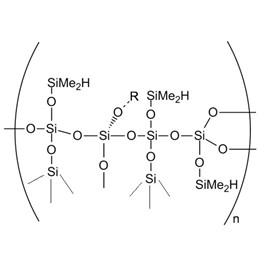

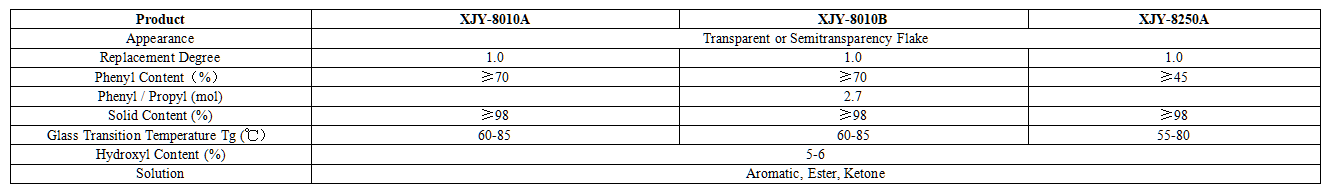

XJY-Flake Methyl Phenyl Silicone Resin

They are silicone resins with light functional groups, which are used in high-temperature-resistant powder coatings and liquid coatings. The first and foremost characteristic of silicone resin is its excellent heat-resistant property, which hardly decomposes under 200℃ or even higher temperatures, and can be used in the preparation of various heat-resistant paints, whose heat-resistant insulation grade can reach H class.

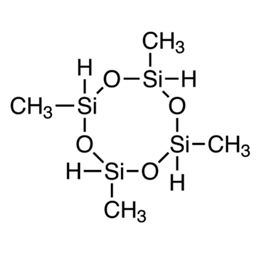

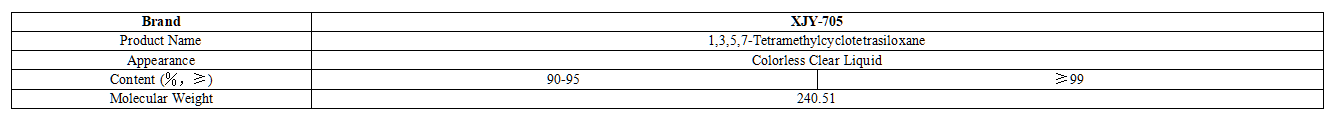

XJY-705 1.3.5.7-Tetramethylcyclotetrasiloxane(D4H)

It is a kind of active silicone containing silicone-hydrogen bonding, which can change with unsaturated olefin by addition. It can be used to synthesize special crosslinking agents for room-temperature vulcanized silicone rubber.

It can be used as reinforcing filler for room-temperature vulcanized silicone rubber.

5. How to apply silicone in optical communication?

Silicon optical communication is the use of silicon photoelectric technology to allow the computer and other electronic devices to send and receive optical signals.

Simply put, this communication technology is to use optical fibres to replace the traditional copper wire to transmit signals, in order to obtain a higher transmission speed. This optical waveguide has good optical performance, extends the optical signal transmission distance to several kilometers, and has better noise immunity than traditional means of communication, which can meet most people's communication needs.

Silicon optical modulators are part of silicon optical communication, simply put, the signal generated by the light source carries a large amount of data and information through the light waves to the modulator, and then a detector is needed to receive this information.

The silicon optical communications linkage system consists of a silicon transmitter and a receiver chip, both of which integrate all the necessary building blocks and incorporate many of Intel's breakthroughs over the years, including the first hybrid silicon lasers developed in collaboration with the University of California, Santa Barbara, and high-speed optical modulators and photodetectors released in 2007.

The transmitter chip consists of four lasers, and the beams emitted through each of them go to an optical modulator, which encodes the data at 12.5 Gbps. The four beams are then pooled and output into a single optical fiber, for a total data transfer rate of 50 Gbps. At the other end of the linkage, the receiver chip separates the four beams and directs them into individual photodetectors, which convert the data back into electrical signals. Both chips are assembled using low-cost manufacturing techniques commonly used in the PC industry.

Silicon photovoltaics will enable a wide range of applications in the computing industry.

For example, home entertainment and video conferencing can also enjoy wall-sized 3D screens; silicon optical communication can also allow supercomputers or future data center components scattered in all corners of the building, each other can achieve high-speed connectivity; silicon optical communication will also enable search engine companies, cloud computing providers and other users of data centers to improve performance, increase functionality, energy and space savings, and can even help scientists to build more powerful supercomputers to solve the world's most difficult problems.

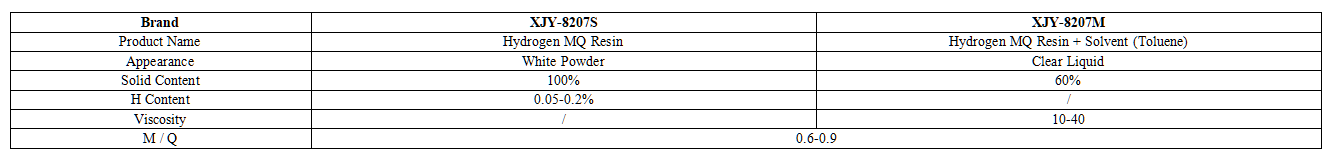

6. How to choose silicone raw materials?

Silicone materials in various forms are mostly half-inorganic half-organic special polymer structures, and silicone materials have high and low temperature resistance, weather aging, water-repellent and moisture-proof, high dielectric strength, and low dielectric loss, optically transparent, safe and non-toxic risk a series of excellent performance. In short, silicone has been widely used in a number of photoelectric materials in the field. Its unique structure and good performance for the study of optoelectronic materials provide broader application prospects. How to make your products more competitive?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers that produce silicone product in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone optoelectronic material products and support the provision of diversified customized solutions.