At present, the commonly used encapsulation materials for LED electronic components mainly include epoxy resin, silicone, and other materials with high transparency. Epoxy resin has become the mainstream material of low-power LED packaging because of its excellent bonding performance, electrical insulation, dielectric performance, low cost and easy molding. But for power LED and printed circuit boards, congenital defects such as strong moisture absorption, easy aging, poor heat resistance and impact resistance of epoxy resin directly affect the service life of LED, and the color change under high temperature and short wave light directly affects the luminous efficiency. It is far from meeting the requirements of packaging materials in terms of high refractive index, low stress and high temperature aging resistance, so it is not suitable for power LED packaging materials.

High-performance silicone potting compounds and encapsulation materials have a series of excellent properties, such as high light transmittance, low internal stress, excellent high and low-temperature resistance, moisture insulation, UV and ozone aging resistance, good hydrophobicity and electrical insulation, and have widely become an ideal choice for LED potting and encapsulation applications materials.

|

|

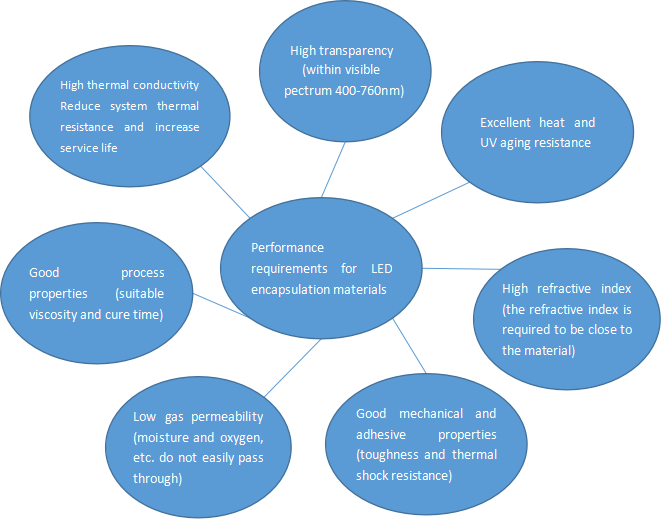

Performance requirements of LED encapsulation materials

Different encapsulation forms require different materials. In recent years, LED has been developing in the direction of high power, high energy efficiency, high brightness and high reliability. This puts forward higher requirements for the optical properties, mechanical properties, aging resistance and construction properties of silicone potting and encapsulation materials. Good optical properties can ensure that LED light can be output more effectively, and good mechanical and adhesive properties can make LED chip-sensitive components better protected. Good aging resistance can prolong the service life of LED, and good construction performance can improve encapsulation compound efficiency.

Characteristics of silicone materials

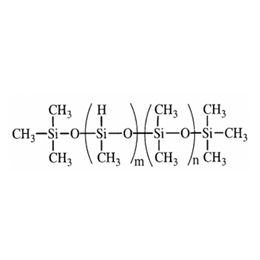

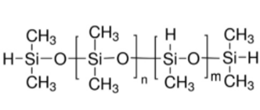

Silicone materials are a kind of polymers with Si-O-Si bond as the main chain and side chains connected with various organic groups through silicon atoms.

Silicone materials have the dual characteristics of both organic polymers and inorganic materials, with high bond energy (452KJ/mol), large bond length (0.165nm), bond angle (109) of Si-O bond, low rotational hindrance of Si-O bond and good flexibility of chain segment, good thermal conductivity.

These inherent properties make silicone rubber materials have a series of excellent chemical resistance properties for protecting electrical components: excellent high and low-temperature resistance, which can work in the temperature range of-50 ℃-250 ℃; excellent aging resistance (heat resistance, ultraviolet resistance, ozone aging resistance), with several decades of service life in the natural environment; good hydrophobicity, surface energy as low as 21-22mN/m2; high light transmittance and very low internal stress; excellent electrical insulation for radiator leak sealing applications, good flexibility for vibration isolation applications, etc.

What is the classification of silicone encapsulant materials

Silicone encapsulant materials can be divided into two categories: low refractive coefficient and high refractive coefficient according to their use. in some special applications, there will be medium refractive coefficient products between them.

The refractive index of encapsulation materials with low refractive coefficient is 1.40 ~ 1.45, most of them are silicone methyl encapsulant materials, and the refractive index of high refractive coefficient silicone packaging materials is 1.50 ~ 1.55, most of which are phenyl silicone packaging materials.

However, due to the large difference between the refractive index of the silicone packaging adhesive with a low refractive coefficient and the refractive index of the chip, part of the light is fully reflected back into the chip, affecting the light output.

At present, the preparation of phenyl-containing vinyl polysiloxane and hydrogen-containing polysiloxane to obtain high refractive index encapsulation materials is one of the more mature and widely used methods. Silicone high refractive encapsulation materials generally use a two-component addition vulcanization system.

What is the curing principle of silicone encapsulant

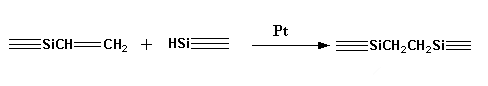

Generally, the curing principle of silicone encapsulant material is to use vinyl silicone resin or silicone oil as the base glue, Si-H containing silane oligomer as the crosslinking agent, and platinum complex as the catalyst to form the encapsulant elastomer resists weathering, high or low temperatures, thermal shock and so on. The addition crosslinking room temperature curing reaction occurs between Si-CH=CH2 and Si-H of silicone polymer under the action of the catalyst.

What is the composition of silicone encapsulant

Silicone potting and encapsulation raw materials are two-component colorless and transparent liquid substances. Component a generally includes base glue, catalyst and tackifier, and component B generally includes base glue, crosslinking agent and inhibitor. A small amount of reinforcing filler and pigment can be added according to the use situation.

1. Base glue

It is mainly an R-vinyl silicone resin / R-vinyl silicone oil, which provides vinyl groups that can participate in the reaction. R groups can be methyl, phenyl, tetrachlorophenyl and aminopropyl, etc., which are endowed with different packaging characteristics by connecting different groups.

Common synthesis methods mainly include functional siloxane hydrolysis condensation method, cyclosiloxane anionic ring-opening polymerization method, siloxane catalytic equilibrium method, etc. vinyl silicone oil or silicone resin can also be prepared by cationic polymerization with acid catalysts such as trifluoromethane sulfonic acid and cation exchange resin.

2. Crosslinker

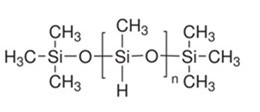

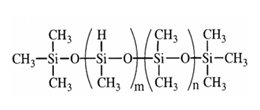

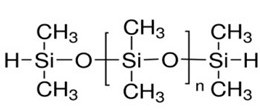

It is generally a low-viscosity hydrogen-containing silicone oil (such as XJY-702 Methylhydrosiloxane, Dimethylsiloxane Copolymer series) or silicone resin (such as XJY-8206 vinyl MQ silicone resin), by controlling the molecular weight of hydrogen-containing silicone oil and functional group distribution and active hydrogen content and distribution, which can improve the performance of silicone encapsulation materials. The commonly used synthesis methods of hydrogen-containing silicone oil are generally hydrolysis condensation or cationic ring-opening polymerization under acidic conditions.

3. Catalyst

In this type of reaction, the catalyst is mainly used to catalyze the addition reaction of vinyl and active hydrogen to fast curing, and complexes such as platinum and palladium are generally used as catalysts. Among them, platinum-based catalysts with higher catalytic efficiency have a high catalytic effect at a concentration of 10-100 ppm.

However, silicone materials for LED encapsulation have high requirements for transparency and catalytic activity. At present, there are kinds of literature showing that the Karstedt catalyst and Speier catalyst are due to the use of tetramethyltetravinylcyclotetrasiloxane, tetramethyldivinyl Ethyl disiloxane, methyl vinyl phenyl cyclopolysiloxane or isopropanol solution are used as coordination solvents, which increase the compatibility with silicone resins and improve the overall performance, and have become the current silicone packaging materials. The most commonly used synthesis catalyst.

4. Inhibitors

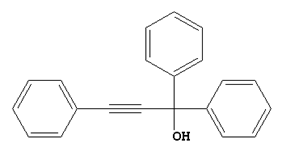

Although the amount used in the reaction system is very small, it plays a crucial role in improving the storage stability of the reaction system, inhibiting the hydrosilylation reaction, and preventing excessive crosslinking. Commonly used inhibitors include ethynyl cyclohexanol, triphenyl propargyl alcohol, heavy metal ion compounds, 6-12-membered cyclic siloxane oligomers containing olefin groups, and benzotriazoles.

Ethynyl cyclohexanol

Triphenyl propargyl alcohol

5. Tackifier

Because there are no reactive groups on the surface of the substrate, ordinary addition-type silicone materials have little adhesion to the substrate. In order to maintain good sealing between the packaging material and the LED device, the packaging material must have good adhesion to the LED bracket and the bottom plate material. A common solution is to introduce tackifiers into LED packaging materials. Commonly used tackifiers include silane coupling agents and silane coupling agents modified (containing epoxy, acryloxy and vinyl) polysiloxanes. A large number of experiments have confirmed that the silicone tackifier modified by the silane coupling agent can greatly improve the bonding and sealing performance with the substrate without affecting its transparency and mechanical properties.

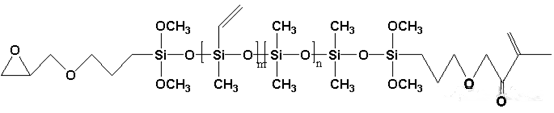

Polysiloxane tackifier modified by silane coupling agent

6. Reinforcing fillers

There are mechanical property issues with traditional two-component addition silicone materials, thus it requires reinforcing filler to meet the mechanical properties of packaging materials.

Commonly used reinforcing fillers mainly include fumed silica and MQ silicone resin, etc. For the special requirements of LED packaging materials for transparency, currently, the most commonly used silicone packaging material reinforcement filler is MQ silicone resin with good compatibility with the system. MQ silicone resin is a kind of silicone resin containing both monofunctional Si-O chain unit (M) and tetrafunctional Si-O chain unit (Q). MQ silicone resins such as vinyl MQ silicone resin and hydrogen-containing MQ silicone resin have good compatibility with the silicone packaging material system for LEDs and the reinforcement effect is obvious.

With the continuous improvement of power and brightness and the rapid development of white LEDs, silicone encapsulation materials have advantageous over EP encapsulation materials. Among them, high-refractive-index silicone packaging materials will be ideal matrix resin for high-power LED packaging. With the continuous breakthrough of technical barriers, the application scope of high-refractive-index silicone packaging materials will continue to expand, and many domestic LED lighting manufacturers will promote and apply it.

XJY Silicones—First choice silicone raw material supplier of potting compounds and encapsulation materials

| XJY Silicones, one of China's leading silicone MQ resin manufacturers, has 30+ years of R&D and manufacturing experience and 15+ related patents in the silicone industry, also can customize the products according to your potting and encapsulating applications requirements. |

Methyl Vinyl VMQ silicone

| XJY-8206 Methyl Vinyl VMQ silicone resin powder: high transparent and high hardness silicone, addition silicone rubber reinforce stuffing | |

| XJY-8206N VMQ silicone oil solution: LED encapsulation silica gel, high transparent and high tearing resistant silica gel |

Cross-linking agent: Hydrogen-containing silicone oil

| XJY-701 Polymethylhydrosiloxane: cross-linking agent for addition liquid silicone |  |

| XJY-702 Methylhydrosiloxane, Dimethylsiloxane Copolymer: cross-linking agent for addition liquid silicone rubber |  |

| XJY-705 1,3,5,7-Tetramethylcyclotetrasiloxane (TMCTS): a special cross-linking agent for synthesizing room temperature vulcanized silicone rubber and addition molding silicone rubber |  |

| XJY-707 Hydride Terminated Polydimethylsiloxane (HPDMS): chain extender for adding liquid silicone rubber, a crosslinking agent for forming a hot vulcanized silicone rubber |  |

|

XJY-711 Hydride Terminated Methylhydrosiloxane Dimethylsiloxane Copolymer: special crosslinker for liquid silicone |  |