|  |

Due to the unique properties of silicone-based compounds, featuring both organic groups and an inorganic backbone, these materials find extensive applications across various industries. Let's explore their key applications:

- Application of polysiloxane in daily and cosmetic products

- XJY's silicone products are also widely used in the personal care and cosmetic industries. The following are related products

- Polysiloxane for medical and health applications

- XJY's methyl vinyl VMQ silicone resin can be used as a raw material to produce the above medical devices

- Polysiloxane in the textile industry

- XJY products can be used as raw materials for polysiloxane side chains or terminal carbon atoms in fabric products. Here are a few of the raw material products for fabrics

Applications in Daily Use and Beauty Products

The early polysiloxane used were dimethicone oils of varying degrees of polymerization, mainly used in a few cosmetic products to increase the lubricity and water resistance of the skin. It will not oxidize and deteriorate under ultraviolet light and cause irritation to the skin. It has good lubricating performance and can form a uniform protective film with water resistance after applying to the skin but without any sticky and greasy feeling and good glossiness. Good permeability, even if the formation of a silicone film on the skin does not affect sweat discharge. It has a slow-release fragrance role, and thus a long fragrance retention period of high stability is chemically inert, with no adverse effects on other components of cosmetics, especially if the active ingredients match well. It has a certain curative effect on certain skin diseases, such as eczema neurodermatitis, and occupational dermatitis with difficulty in sweating. Silicon dioxide and silicone oil are the most widely used. Among various silicone oils, methyl silicone oil is the most widely used and is the most important variety of silicone oil, followed by methyl phenyl silicone oil.

Organopolysiloxanes are now widely used in skincare, hair care, beauty products, and special products such as antiperspirants and deodorants. Organosiloxanes are very heat resistant, so they do not easily melt, like most other organic compounds. Through a large number of long-term physiological, toxicological, and genetic experiments, it has been confirmed that some silicon compounds organopolysiloxane are safe, reliable, and have excellent chemical properties, such as light transmission and UV resistance: non-toxic, high permeability, high temperature and low-temperature resistance, low surface energy, odorless, permeability to gases, excellent mechanical properties, and with good surface activity, these characteristics make organopolysiloxane in cosmetics are increasingly widely used. Polysiloxane has a number of outstanding advantages for use in personal skin care products. In comparison with a variety of ingredients commonly used in personal care products (petroleum jelly, white oil, etc.), it was concluded that methyl groups polysiloxane with a viscosity of 315 × 104 (m2/s) was the best in terms of spreadability, emollience, and softness, and that silicone skin care does not clog the pores of the skin surface and reduces acne.

XJY's silicone products are also widely used in the personal care and cosmetic industries, the following are related products.

1.XJY-8203/ 8205 Trimethylsiloxysilicate

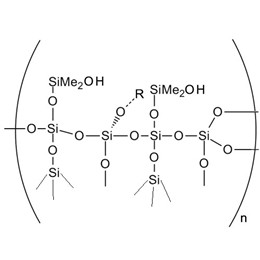

XJY-8203 / 8205 Trimethylsiloxysilicate is a series of solid silicone resin powders, these silicone resins have been specially developed to provide film forming and softness effects. With the alkyl groups pointing to the outside, silicones produce hydrophobic films. It can provide excellent water repellency and resistance to detergent/ water wash-off and a flexible film with a smooth and comfortable touch on the surface of many skin care products.

2.XJY-056 Phenyl Trimethicone

XJY-056 personal care products can improve the glossiness and better softness of hair conditioner products and have non-greasy and easy-to-apply emollients in skin conditioner products, which has high application in the beauty industry.

3.XJY-801 For Personal Care Polymethylsilsesquioxane PMSQ

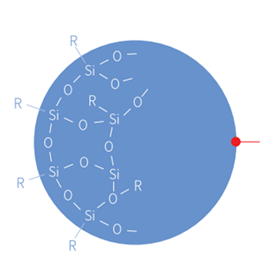

Polymethylsilsesquioxane is a silicone ingredient that can be used in many skincare and cosmetic applications and has good spreading properties in skin care and sun care treatments. Polymethylsilsesquioxane is primarily used to protect and condition the skin, to reduce the appearance of fine lines and wrinkles through the use of foundations and decorative cosmetics, and to help improve the repair of aging skin as it occurs.

Polysiloxane for medical and health applications

Polysiloxane, depending on the molecular weight, polysiloxane can be oiled, greased, rubbered, or plastics. They are characterized by unique material properties combining biocompatibility and durability and have found widespread application in health care. The materials' high durability is a result of other material properties such as hydrophobicity, low surface tension(liquid silicones), and chemically and thermally stable. Silicone surfaces have been found to inhibit the blood from clogging for many hours and thus have been used to fabricate silicone-coated needles, syringes, and other blood-collecting instruments. Because organopolysiloxane has many advantages such as being non-toxic and tasteless, good biocompatibility, no skin sensitization, strong physiological inertia, unique solution permeability, and various physical and silicone chemistry properties stability, it is widely used in the medical and healthcare field. Silicone chemistry is remarkably versatile because silanol groups readily react with many other functional groups.

In medical devices, silicone medical grade materials have unique and irreplaceable advantages in medical device applications and are being adopted by more companies in medical applications. Medical silicone rubber catheters made from organopolysiloxane are the most versatile and fastest-growing medical catheters. Promising progress has been made using the unique permeability of silicone rubber to make biodegradable microlenses for the diagnosis and treatment of cancer.

Silicones have been used in a variety of applications including intraocular lenses, silicone implant bandages, scar treatment sheets, and Silicone Breast Implants (liquid silicone), Silicone was first used for breast implants in the 1960s for women who had undergone mastectomies, surgical removal of their breasts. Silicone implants later became popular with women who had no medical problems but wanted larger breasts. They are also water-repellant and can withstand extremes of sunlight, moisture, cold, and attack by most chemicals. These properties make them useful for medical protective coatings, electrical insulation, and adhesives. Silicone elastomers have been used in numerous catheters, drug delivery systems, shunts, drains, and tubular implants such as the artificial urethra. From infusion tubes, cochlear implants, and prostheses to orthodontic dental molds and wound care, silicone materials are actively protecting human health in a variety of forms.

XJY's methyl vinyl VMQ silicone resin can be used as a raw material to produce the above medical devices.

1.XJY-8206 VMQ Silicone resin

XJY-8206 vinyl methyl silicone resin is a silicone polymer and silicone compound made from VMQ material. It has physical properties such as resistance to a wide range of temperatures, abrasion, weathering, pressure, and ultraviolet radiation, which improves the use of medical devices and effectively reduces costs, etc. Therefore, it is widely used in the medical industry.

2.XJY-8206N VMQ Silicone Solution

XJY-8206N VMQ silicone resin (Trimethylvinylsiloxysilicate) is a colorless and transparent liquid resin composed of VMQ silicone resin and vinyl silicone oil. It can help provide high-transparency silicone rubber, which is important for the production of infusion tubes, translucent medical devices, etc., in the medical field.

3.XJY-8206 for Dental Methyl Vinyl MQ Silicone Resin

VMQ silicone rubber and two-component additive silicone rubber systems are increasingly used in the dental field, with the advantages of good elasticity, high precision, and great stability for a variety of dental restorations and precision cast dentures.

Polysiloxane in the textile industry

The compounds formed by amino or arylamine groups attached to the side chain or the terminal carbon atom of polysiloxane are mostly used in the textile industry as finishing agents, softeners, and combustion aids for fabrics, etc. It can effectively reduce the generation of static electricity in textiles, improve the softness of fabrics, and increase their storage stability.

For example, on polyester-cotton fabrics, high polymerization levels of amino-modified polysiloxane can give the fiber a cotton-like feel, while low polymerization levels of amino-modified polysiloxane give the fiber a smooth, silky feel. Experiments were conducted with polyester cotton woven fabric, and it was found that the tear strength of the fabric adsorbed with 1% amino-modified polysiloxane could be increased by 30%, resulting in a significant increase in tear strength and a significant increase in resilience.

XJY products can be used as raw materials for polysiloxane side chains or terminal carbon atoms in fabric products. Here are a few of the raw material products for fabrics.

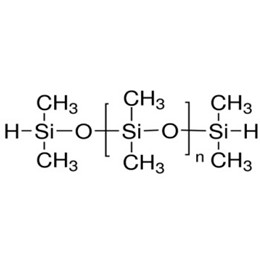

1.XJY-707 Hydride terminated Polydimethylsiloxane

XJY-707 hydride terminated polydimethylsiloxane is commonly used in the production of textile softeners, blocking silicone oils, surfactants, and as a water repellent and a softener for natural and synthetic fabrics.

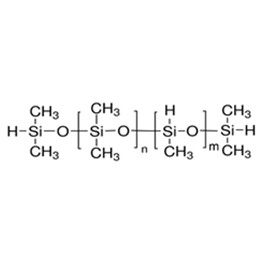

2.XJY-711 Hydrogen terminated methyl hydrogen siloxane dimethylsiloxane copolymer

As a water-repellent and finishing agent for fabrics, it improves the service life of fabrics.

3.XJY-706 1,1,3,3-Tetramethyldisiloxane

Superior water resistance and stability, suitable for leather products, and textiles, so that the color, feel, and breathability will not change, and the waterproof effect is long-lasting.

XJY Silicones-Excellent Choice for Silicone Rubber Raw Material Supplier

XJY Silicones, one of China's leading Silicone MQ resin and VMQ silicone manufacturers, has 30+ years of R&D and manufacturing experience and 15+ related patents in the silicone industry. Can customize the products according to your potting and encapsulating requirements.

![]()