Nowadays, products with fabric water resistance are more and more commonly used in people's daily lives to solve the mess resulting from sudden bad weather conditions. From the perspective of cost, water resistance, and various other factors, manufacturers are always seeking more effective materials for moisture protection. This article explores which materials can be applied as moisture barriers and the reasons why they are preferred.

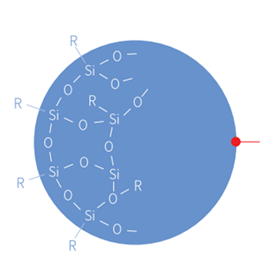

Silicone materials, recognized as non-polluting, non-irritating, and highly efficient waterproofing agents, have found widespread application in many industries, including construction and fabric water repellent solutions. These agents are emerging as advanced alternatives in many developed countries around the world.

Let’s discuss the following points:

Then let’s talk below:

- Differences between silicone and traditional water repellent

- Why water repellent is necessary? (Typical examples)

- Application (Construction, Fabric)

Silicone vs Traditional

Silicone waterproofing agent

- Not only by physical action. Mainly by the chemical effect, the formation of a moisture-barrier layer waterproof

- Non-toxic and tasteless, green products

- Belong to organic inorganic composite materials, non-aging, can improve the compressive strength of concrete, long-term water resistance, and extend the life of concrete.

- Capable of penetrating into concrete for overall water resistance

- Resistant to high and low temperatures, strong resistance to freeze-thaw cycles

- Breathable, keeping the building dry

- The base surface is allowed to be wet, and no leveling layer is required

- No need to fill and trim corners, joints, and edges, no overlap to ensure waterproofing integrity

- It can be completed simultaneously with the mixed concrete, which can shorten the construction period, simplify construction operations, and lower overall cost.

- Good waterproofing effect, long service life, and no maintenance

Traditional waterproofing materials

- Most rely on physical covering for waterproofing concrete surfaces

- Many emit irritating odors, may be toxic, and potentially harmful to humans

- Do not improve concrete strength and are prone to aging, limiting their effective lifespan

- Offer limited or no permeability into surfaces

- Poor resistance to temperature fluctuations and freeze-thaw cycles

- Hardly breathable

- Requirement for dry surfaces and a leveling layer before application

- Joints, corners, and edges need special attention; overlaps can cause leakage risks

- Cannot be applied concurrently with concrete construction; operation is more complex and labor-intensive, making the total cost higher

- Short service life, frequent maintenance is required

Why Is Moisture Protection Essential?

Barriers to moisture not only prevent water intrusion but also protect against steam and other harmful gases, stopping corrosion of the material underneath. At the same time, they help prevent frost, moss, and weathering by isolating moisture and liquid water to reduce the risk of deterioration.

A few typical examples:

1. For Metals

| Because of water-resistant properties, durable water repellent materials can prevent water from penetrating to the metal surface; prevent moisture, steam and other harmful gases and liquids in the air from corroding metals, and slow down metal oxidation, especially the rate of rust, oxidation and corrosion of steel in a high-humidity environment Several times the dry environment, so the water repellent treatment of steel can greatly improve its durability. |

2. For stone

| Stone water repellent is the water repellent of stone and brick products such as marble, cultural stone, artificial stone, chopping stone, ceramic tile, mosaic, inscription, and other stone and brick products.

In a certain marble floor tile, the comparison between two pictures without water repellent and water repellent is very obvious.

In addition, the stone is treated with professional water repellent before construction, so that it will not be polluted by the outside world, and it will always maintain a beautiful and new effect. |

3. For wood

Application

1. Building wall

Moisture-resistant technology is employed on various exterior walls such as brick, ceramic, and natural stone. Treated surfaces offer resistance to rain and seepage, retain color, resist stains, and combat weathering—all while retaining the original appearance.

-

Excellent waterproof performance

| Walls treated with silicone products act much like waterproof fabric, repelling rainfall and maintaining dryness. The result is similar to the lotus leaf effect—keeping walls dry thanks to outstanding water and mildew resistance. |

-

Good air permeability

General waterproofing agents block pores and capillaries, isolating water and external air but impeding moisture emission from within building materials. This impermeable feature can result in blistering or peeling of coatings. Silicone moisture-protection agents, however, manage both breathability and waterproofing.

-

Moisture-proof, mildew-proof, and no moss

Keep the room dry in a humid environment, especially suitable for (food) warehouses, residences, archives, libraries, etc. It is used on the joints of tiles and mosaics. Because it does not absorb water, it will not freeze and expand in winter, which can prevent the tiles and mosaics from peeling off. Used on natural stones such as monumental stele towers, it can prevent the growth of moss and keep the surface clean.

-

Anti-pollution, anti-weathering, and color retention

| When used in gardens, stone buildings, red or yellow powder walls, statues, and monuments, this technology can effectively prevent staining from rain and maintain the original appearance. The surface does not readily collect dust, so even after rainfall, it remains clean and attractive. These treatments defend against aging and weathering, offering long-term preservation, especially for cultural relics. |

-

Good durability

This method provides excellent long-term performance. The solution can penetrate deeply into the wall, reducing the impact of sunlight and environmental aging, so the protective effect can last for many years.

-

Detailed application: Gypsum Board

Gypsum Board, also known as wallboard or plasterboard, is a popular material for making interior and exterior walls and ceilings. One major advantage is its natural resistance to moisture. Gypsum contains hydroxyl groups, which react with hydrogen to create a thin protective layer, enhancing its ability to repel liquid.

There is a reason why the gypsum board is one of the most common names among all paneling products. Compared to different paneling materials such as fiberboard, hardwood, and plywood, the gypsum board stands out for its inherently water-repellent advantages. Gypsum board with a hydroxyl group, and it will react with a hydrogen group to form a water repellent film.

2. Waterproof fabrics

With the improvement of people's living standards, functional fabrics such as fabric water coating technology are becoming more and more popular among consumers. Commonly used moisture-resistant clothing focuses on four aspects: resistance to water, oil, dirt, and ease of cleaning. After special textile finishing, fabrics can gain all four of these protective qualities.

The so-called waterproofing of fabric is about reducing water absorption, so that water beads up and rolls off, rather than soaking immediately through the surface. While prolonged exposure to water may eventually allow moisture to pass through, these fabric water treatments offer much better breathability and comfort than traditional coatings.

| Cloth treated with hydrophobic materials repels moisture quickly, preventing wetting and keeping the wearer dry—even during heavy rain or high-pressure water exposure. In contrast, everyday untreated clothing with hydrophilic surfaces gets soaked almost instantly. If you quickly wipe water droplets off a treated waterproof jacket, the fabric stays dry. |

The principle of oil and dirt resistance is similar: it works by altering the surface properties of fibers. The finishing creates a protective barrier that combines with the fibers, so oil and everyday stains do not penetrate.

Fabrics that resist both water and oil are called functional or smart textiles. These fabrics not only keep off rain and dirt but also let sweat and heat escape, maintaining comfort. Such moisture- and stain-resistant technologies are increasingly used in daily life, from tablecloths to car covers, and continue to gain favor in decorative and industrial fields.